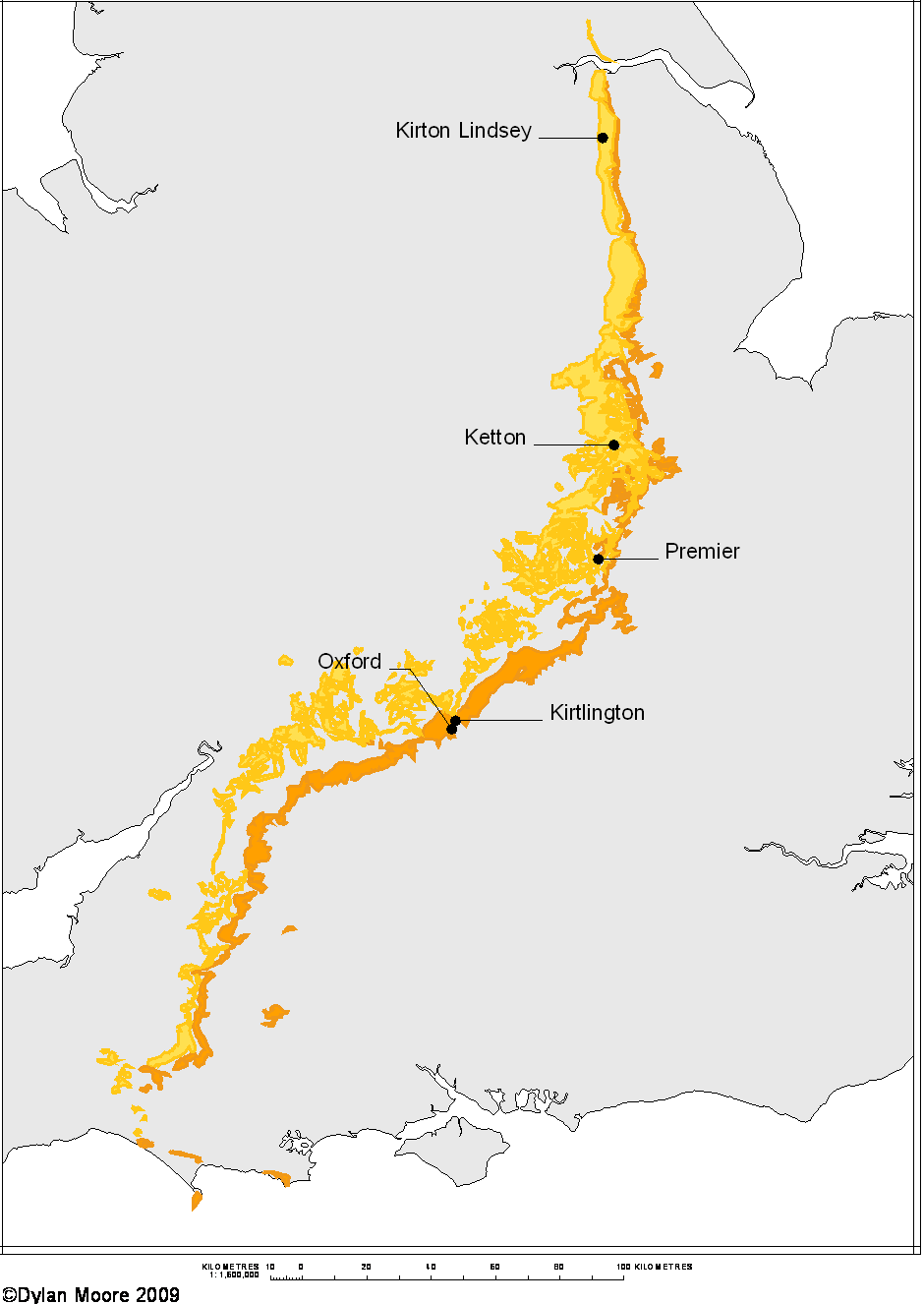

Limestones form successive escarpments across England at several levels in the Jurassic. These lie somewhat north and west of the chalk escarpment, and have been used for millennia as building stones, notably the Cotswold stones and the Rutland and Lincoln limestones. These generally make excellent dry-process raw materials, being reasonably soft when freshly quarried, but fairly dry (3-6% water).

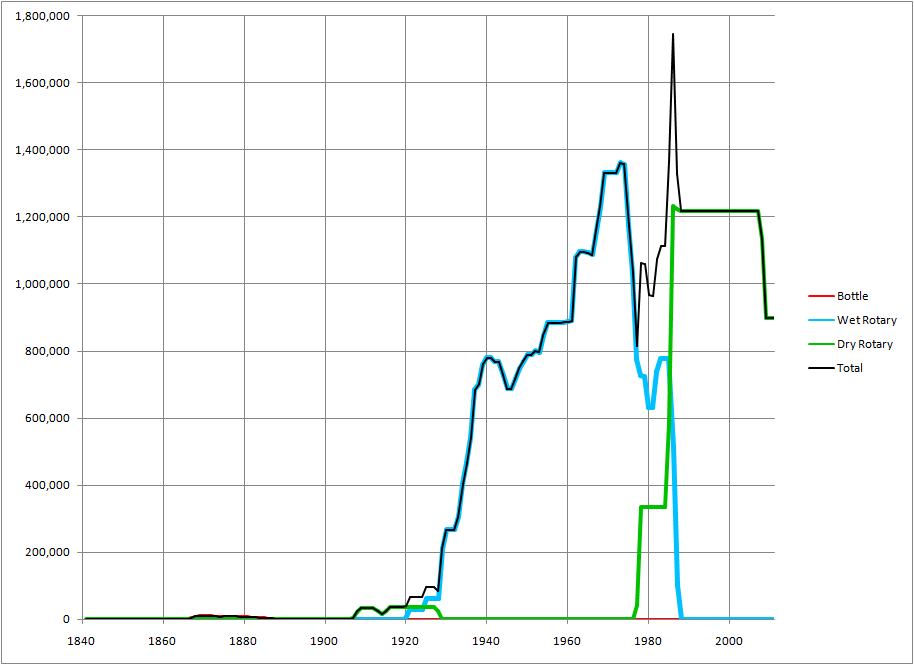

In the map, “Inferior Oolite” is shown in yellow, and “Great Oolite” limestones and the Cornbrash are shown in orange. Despite the attractiveness of these limestones as cement raw materials, only five plants appear within the timeframe of this work. All five plants began operation late, the first being Premier in 1898. Although both Premier and Kirtlington used Dry Process, the materials being eminently suitable for this, the other three plants used wet process, with Ketton commencing dry processing as late as 1977. Blue Circle let slip away the opportunity to create an efficient dry process plant at Oxford, and Ketton is the only plant remaining in 2009. For supply of cement made by efficient dry process to London and the southeast, these limestone outcrops provide the nearest suitable raw material.

At Ketton, the limestone is sufficiently high-grade to require addition of clay, and the overlying Great Oolite Clay is used. At the other four plants, different grades of argillaceous limestone or inter-bedded limestone and shale were blended, without (usually) clay addition.

In addition to these five plants, some Blue Lias plants - notably Barnstone, Harbury and Stockton - brought in high-grade oolitic limestone from some distance away to act as a "sweetener".