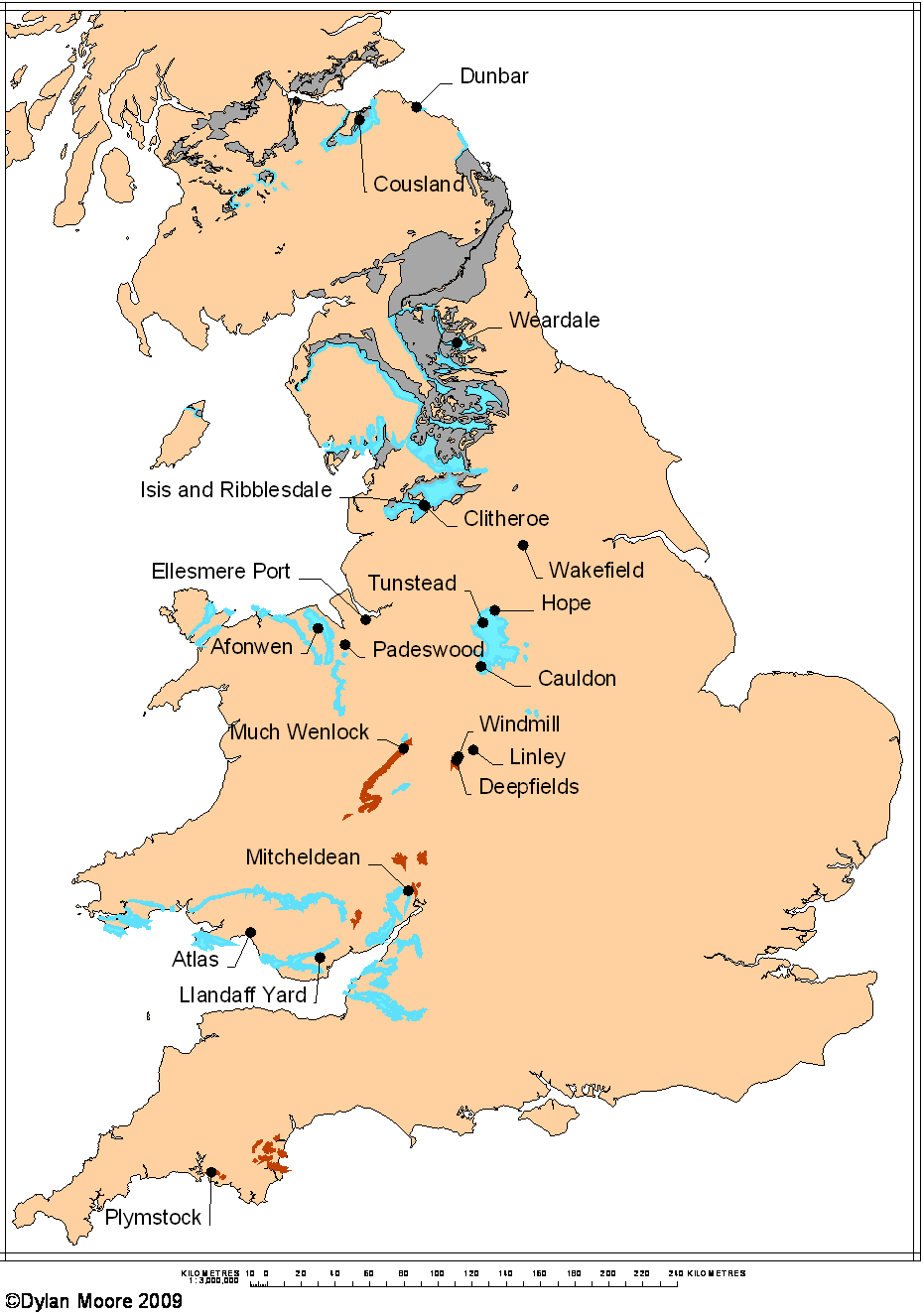

These, in Britain and Ireland, are confined almost solely to the Carboniferous Limestone ( Mississippian in US parlance). The limestone occupies most of the Dinantian epoch (326-359 million years old) at the base of the Carboniferous. It is familiar in the Mendips, the Peak District and the Pennines, and as narrow outcrops surrounding the coal fields. It also covers much of Ireland, where the “bog-and-lake” landscape is the characteristic limestone scenery (see Ireland). The formation is very variable chemically: in places it can reach very high levels of purity with low magnesia, but elsewhere it varies in a rather unpredictable manner, yielding dolomitic limestones, shales and sandstones. Mineralization with lead, zinc etc is common. The limestone is often high in chert. Cherty limestones often make excellent raw materials due to the easy combination of their silica content. Where the chemistry is good, these limestones are the best for low-cost cement manufacture using modern dry-process equipment. Towards the north of the formation (northern England and Scotland), it is progressively more represented by sandstones, and limestone of cement-making quality is rare in Scotland, occurring in significant quantity only in the Lothians. The Middle Coal Measures (US: Pennsylvanian) in the West Midlands contain thin seams of argillaceous limestone, and these were used at one time to make what was very loosely termed “Roman Cement”, and latterly attempts were made to use them for Portland cement.

Other limestones are rarely used: Devonian limestone characteristic of the Torbay and Plymouth areas has been used at only one plant. Ludlow and Wenlock Limestones of the Silurian are widespread in Wales and the Midlands, but rarely meet cement-manufacturing chemical requirements. They have been used at a few small plants.

Pre-carboniferous limestones (Devonian and Silurian) are shown on the map in red. What is referred to on maps as “Carboniferous Limestone” is variable, and not all of it is actually limestone, let alone limestone of the quality required for Portland cement manufacture. In the map, the blue areas are outcrops in which limestones are common, while in the grey areas they are rare.

The earliest plant in the group was, of course, the Aspdin plant at Wakefield. However, Aspdin’s process was painfully complex, involving double burning, so when the industry got under way on the Thames, no new entrant was likely to consider hard rock raw materials. The earliest subsequent plants in this group were those in the West Midlands that used localised argillaceous stones to make ersatz “Roman Cement”. The first plant to make a proper Portland cement mix (albeit of poor quality) was probably Afonwen, around 1874. The primary problems with the material were its hardness and its variability, necessitating competent chemical supervision, which was not commonly available before the 1890s.

This was the situation in Britain: serious chemical control on cement plants began in Germany 20 years earlier.

Many subsequent small plants used dry processing techniques first developed for Blue Lias.

The first plant in the group to install a successful rotary kiln was Mitcheldean, and this used wet process.

A first-generation dry process Ransome kiln had been unsuccessfully tried much earlier.

The next was Ellesmere Port, where dry process was tried, but soon abandoned, probably more due to the incompetence of its promoters than real problems with the dry process. Despite the obvious suitability of the material for dry processing, the next three plants (Hope, Ribblesdale and Padeswood) all used wet process – Ribblesdale had the distinction of installing Britain’s last wet kiln as late as 1976. Starting with Cauldon in 1957, a number of semi-dry and dry process kilns were installed, and Hope was converted to dry process in 1970. The last wet kiln to operate was at Tunstead, replaced by dry process in 2004. As of 2009, all but four of the fifteen plants still operating are in this group.

Because Carboniferous Limestone is often high grade, it was used by some plants as a "sweetener" to raise the calcium content of marginal local raw materials. Notable in this context are the South Wales Blue Lias plants. The slag-burning plants in Scotland used local stone, often supplemented with high grade stone brought in by ship from the coastal quarries of North Wales, and otherwise destined for the steel industry.