Click the plant name to reach the plant page uless map is resized by device. Use your back button to return to the map.

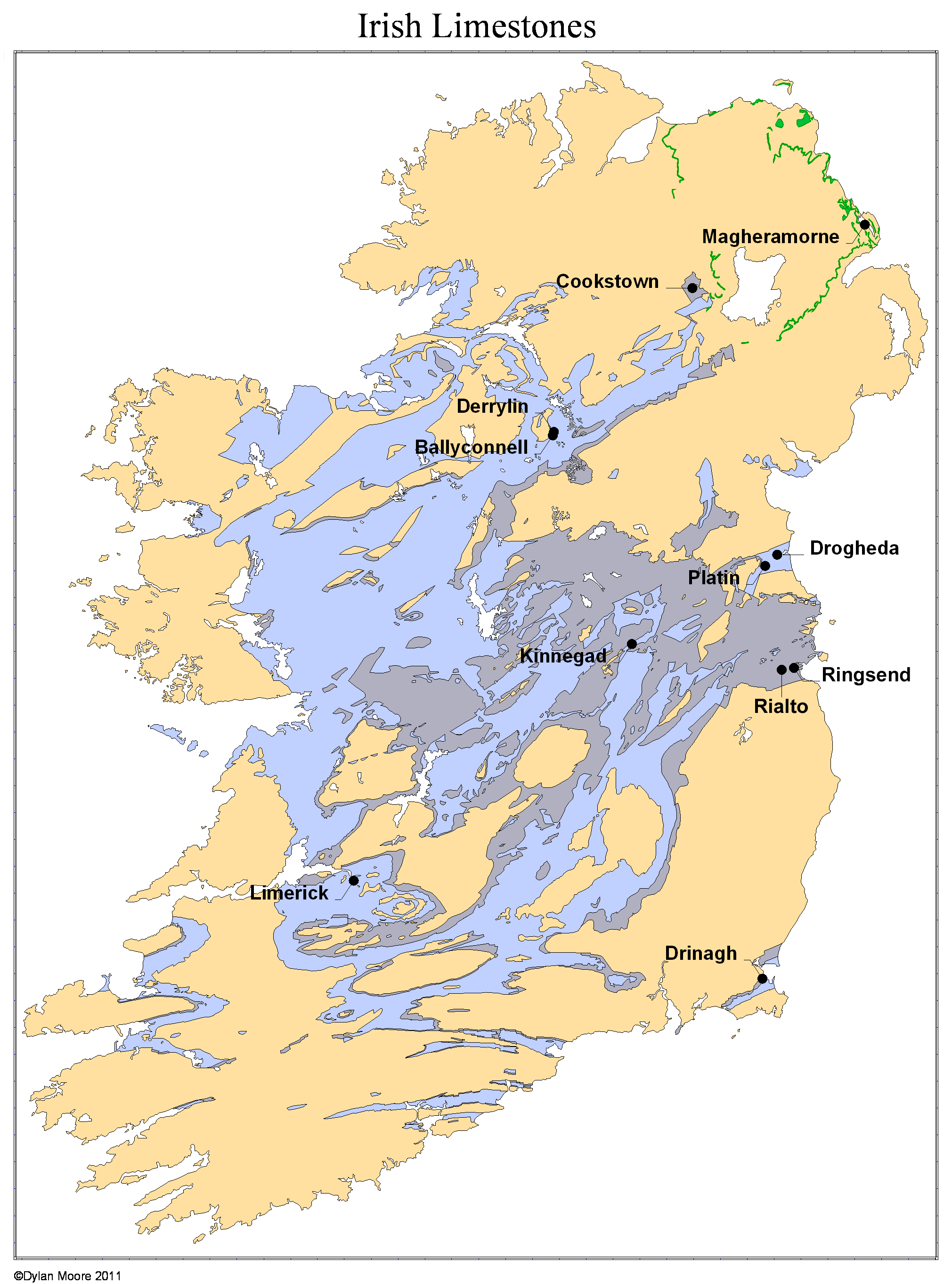

Ireland is particularly well supplied with cement raw materials, most of which allow a highly efficient manufacturing operation. Of the limestones of Britain, only the Chalk and the Carboniferous Limestone are present, but the outcrop of the latter occupies much of the island. Low-lying Carboniferous Limestone, subject to solution weathering, contributes the characteristic "bog and lake" morphology of the Irish midlands. Despite the eminent geological suitability of Ireland as a cement-producing region, the industry's growth was slow and faltering, partly because of a small local market, and partly because of a distinct tendency of the British industry to suppress Irish ventures by dumping. See article.

The Chalk, which may once have covered much of Ireland, is now confined to the northeast of Ulster, where it has been protected from the erosive forces at work elsewhere by the massive basalt flow of the Antrim Plateau, which was erupted over the Chalk during the Paleocene 56-61 million years ago. The Chalk, which is around 150 m thick, is similar to the British Chalk, with flints, but is considerably harder, drier and denser. Portland cement manufacture in Ireland probably commenced in 1868 at Greencastle (Belfast) using outcrop chalk. Only one post-1895 plant (Magheramorne) used chalk, this involving stripping back a great thickness of overlying basalt. The cost of this explains why Chalk was not used elsewhere.

The Carboniferous Limestone, as in Britain, has varying purity, both vertically and laterally, and is subject to dolomitisation in a rather unpredictable way. However, the extent of the outcrop is such that, although the lower-lying midland limestones are often below the water table, there is no shortage of workable high purity stone. The first Irish plant to use Carboniferous Limestone was Drinagh from 1881, using a coastal deposit already in use for lime manufacture. Argillaceous limestone ("calp") was used at Rialto and Ringsend.

Despite the suitability of all the raw materials for dry process, and the relatively high price of imported fuel in Ireland, it was not until the building of Cookstown in 1968 that a dry process rotary kiln was employed. Nevertheless, conversion to dry process was relatively rapid after this, and the last wet kilns to operate were those at Limerick shut down in 1983.

The remaining (2016) six operable plants consist of one Lepol kiln, two air-through precalciners and four air-separate precalciners - a setup potentially as efficient as in any geographical region in the world.