Rotary Kiln Processes

With the arrival of rotary kilns in Britain in 1900, cement manufacturing processes became sharply defined according to the form in which the raw materials are fed to the kiln. Raw materials were either ground with addition of water, to form a slurry containing typically 30-45% water, or they were ground dry, to form a powder or "raw meal".

- In the Wet Process, the kiln system is fed with liquid slurry, the water then being evaporated in the kiln.

- In the Semi-Wet Process, raw material is prepared as a slurry, but a substantial proportion (50-80%) of the water is mechanically removed, usually by filtration, and the resulting "filter cake" is fed to the kiln system.

- In the Dry Process, the kiln system is fed with dry raw meal powder.

- In the Semi-Dry Process, a limited amount of water (10-15%) is added to dry raw meal so that it can be nodulised, and the damp nodules are fed to the kiln system.

In addition to these distinctions, a further category has emerged in the last 50 years: Precalciner Kilns, in which a proportion of the kiln fuel is burned in a static preheater before the feed enters the rotary kiln.

Rotary kilns are discussed under the following headings:

| Early rotary kilns |

| Design features of rotary kilns |

| Wet and semi-wet kilns |

| Dry and semi-dry kilns |

| Precalciner kilns |

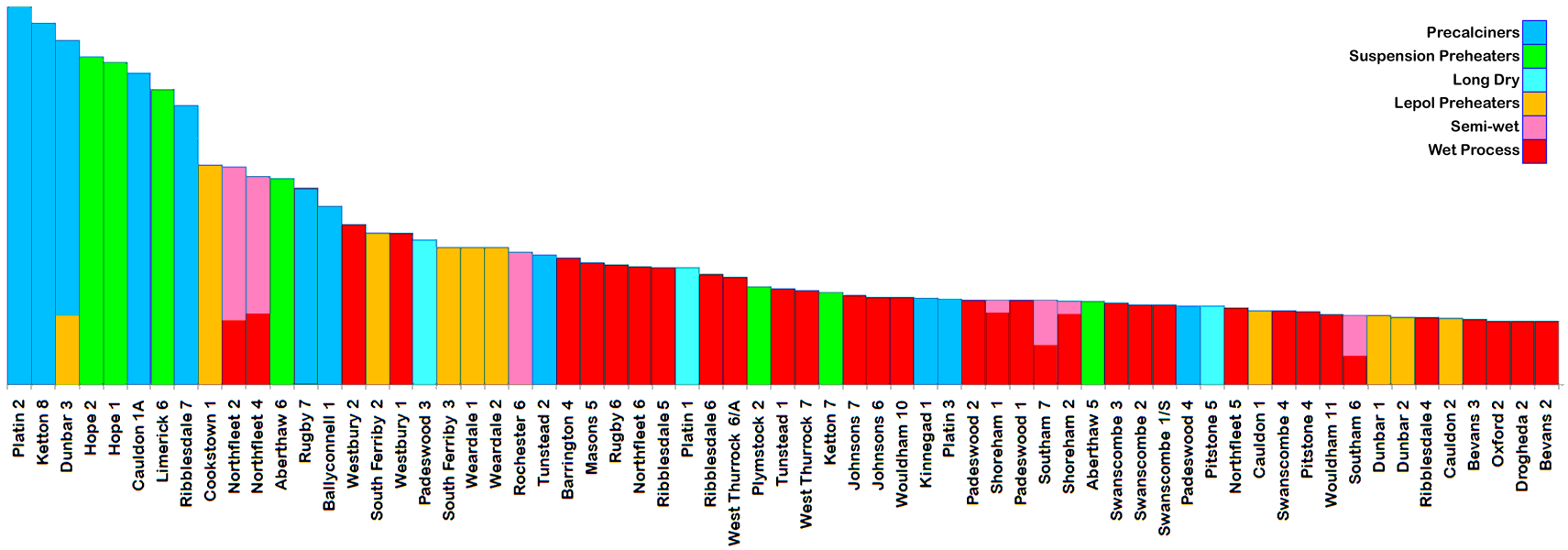

Approximate production to 2016: all kilns that have produced over 5 million tonnes of clinker