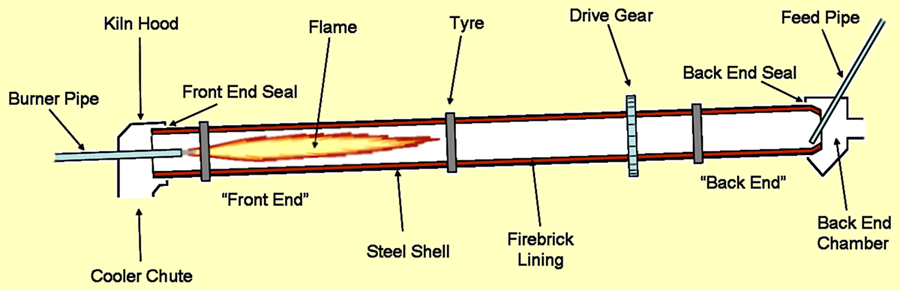

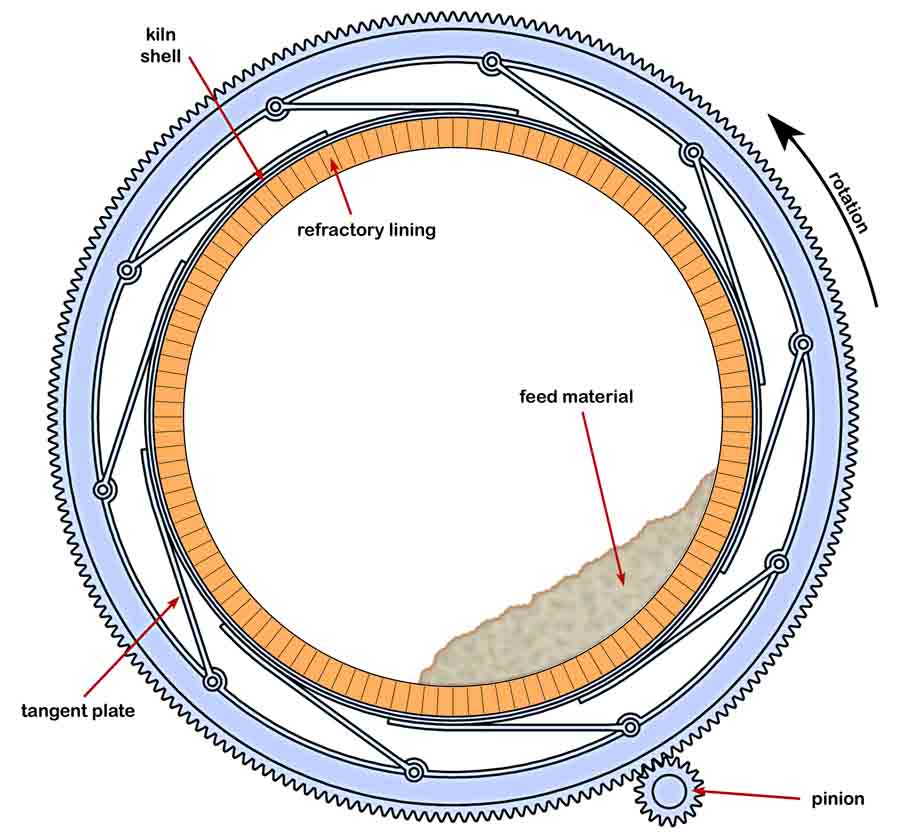

Rotary kilns systems have evolved considerably in form and complexity over the last 120 years, but the kilns themselves have certain common features. This page lists these and describes their evolution.

Rotary kiln terminology

Rotary kiln terminology

Rotary kilns systems have evolved considerably in form and complexity over the last 120 years, but the kilns themselves have certain common features. This page lists these and describes their evolution.

Rotary kiln terminology

Rotary kiln terminology

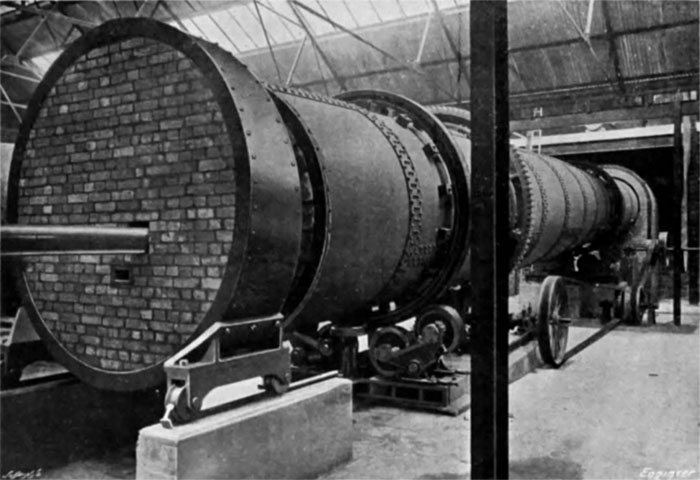

Picture: ©NERC: British Geological Survey Cat. No. P540333. Front end of Ribblesdale Kiln 2 (constructed 1937): shell constructed mainly from staggered semi-circular sections, with all joints riveted.

Picture: ©NERC: British Geological Survey Cat. No. P540333. Front end of Ribblesdale Kiln 2 (constructed 1937): shell constructed mainly from staggered semi-circular sections, with all joints riveted.

Picture: ©Rugby Archive: Cat. No. RC-3-6-8. Back end of Southam Kiln 7 (constructed 1961): shell entirely welded. The shell still consists of staggered half-cylindrical sections.

Picture: ©Rugby Archive: Cat. No. RC-3-6-8. Back end of Southam Kiln 7 (constructed 1961): shell entirely welded. The shell still consists of staggered half-cylindrical sections.

The shell of the kiln is made of mild steel plate. Mild steel is the only viable material for the purpose, but presents the problem that the maximum temperature of the feed inside the kiln is over 1400°C, while the gas temperatures reach 1900°C. The melting point of mild steel is around 1300°C, and it starts to weaken at 480°C, so considerable effort is required to protect the shell from overheating.

Historically, the construction of rotary kiln shells has closely paralleled the construction of boilers.

The engineers who pioneered the first rotary kilns all had a background in locomotive construction.

Shell sections were made from flat rolled plate, of thickness typically in the range 18-25 mm. The plate was cold-rolled to the required curvature, typically into semi-circular pieces. Two of these were then joined to make a cylinder, usually of length about equal to the diameter. The pieces were butt-jointed together using a strap of steel plate of similar thickness attached with rivets. The cylindrical sections were joined end-to-end in a similar manner. Short sections were usually assembled at the factory, and final assembly was performed on site, with the kiln in place.

Riveted construction continued until WWII. The technique of making welded joints in such heavy plate by arc welding developed in the USA. As in the shipbuilding industry, welding was adopted only rather slowly in the UK. Welding has the obvious advantage that a lighter construction is possible, without the extra weight of the straps. Kiln suppliers began to use welding after WWII, but on-site assembly continued using rivets because of the lack of the required skill at cement plants. Typically sections of length up to about 10 m - the longest that could be moved by road - were welded, then riveted together when in place.

Finally, from the late 1950s, all-welded kilns were installed. Although welded construction reduced the weight of kilns, it had the distinct disadvantage that the shell, without the reinforcement of thick straps, became somewhat less rigid, despite the adoption of thicker plate (25-35 mm).

Except for the very earliest kilns, the shell was strengthened at the location of tyres and turning gear by providing extra layers - "wrapper plates" - of steel, either riveted or welded on, in order to resist the high flexural forces encountered there.

The ends of the kiln have special features. At the back end there is often either a conical constriction or a "closure plate" reducing the diameter, both intended to prevent the rawmix from spilling over the back of the kiln. At the front end, clinker at 1200°C or more is flowing over the lip of the kiln, and the shell is subject to very aggressive conditions. Castings of heat resistant steel are attached to the end of the mild steel, contoured to retain the refractories of the nose ring. Because the shell inevitably gets hot, the tendency is for the steel to "bell out" at the end, until the brickwork will no longer stay in. Because of this, early kilns were supplied with easily replaceable nose sections. Modern kilns keep the nose cool with elaborate systems to duct pressurized cold air around the outside of the nose.

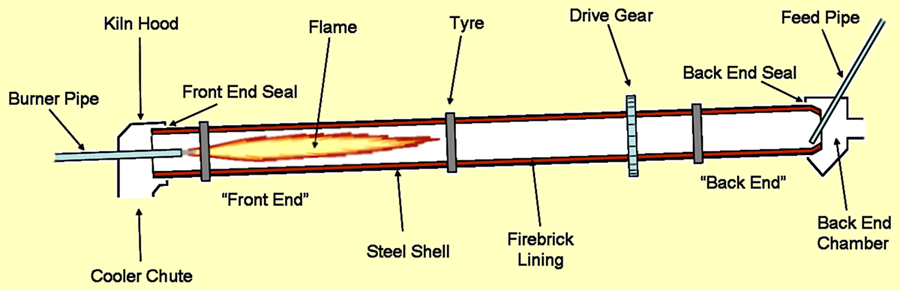

Early rotary kilns were simple cylinders. However, the idea that different parts of the kiln ought to have different diameters emerged quite early. Before 1900 in the USA, kilns were being installed with the front (hot) half having a shell diameter 20-30% greater than the rear half. A wider burning zone with a reduction in its diameter at the outlet end was favoured because this was considered to produced a zone in which the material bed depth was increased, thereby slowing material flow down, and allowing clinker to "soak" at the peak temperature. A further, more practical reason for a wide burning zone shell was that it allowed room for thicker refractory and for thick coating that usually forms in this zone.

The provision of expanded zones in other parts of the kiln enjoyed periods of popularity at various times. Expanded mid ("calcining") zones were advocated in the 1920s, while various forms of expanded rear (cold end) zones had a long and continuing popularity, these becoming more standard as it became known that most "long" kilns are limited in their capacity by the gas velocity at the back end. At the same time, there has always been a strong body of opinion in favour of "straight" kilns, it being argued that the benefits of expanded sections are outweighed by their disadvantages - the tapered sections are mechanically weak and hard to line with stable brickwork.

The wet process kilns at Dunstable: No 1 at the top. The kilns are 30 ft apart. These exemplify the variations - often eccentric - in shapes of wet process kilns.

The wet process kilns at Dunstable: No 1 at the top. The kilns are 30 ft apart. These exemplify the variations - often eccentric - in shapes of wet process kilns.

The early commercially successful rotary kilns in Britain were nearly all "straight" cylinders, the exceptions being those at Norman (1904). Lengthening of the early kilns at Wouldham and Bevans resulted in kilns with enlarged burning zones, while the lengthened kilns at Swanscombe had enlargements at both ends. Among new installations from 1909 to 1914, only 15 out of 44 were "straight", the rest having enlarged burning zones. The pattern was repeated in the 1920s, when 46 out of 57 new installations had enlarged burning zones, and of those, four also had enlargements at the cold end. The latter included the Lewes kiln, which was the first of what became a common FLS design, with elongated wide front and rear sections, and a narrower "waist" occupying the middle third. The other back-end enlargements were by Vickers, who during the 1930s offered short, large-diameter back-end "bulges" both on new kilns and as retrofits to existing kilns - for example they were fitted on the FLS kilns at Wilmington and Hope. These were supplied as part of the project to fit wet kilns with chains, and led by 1938 to the development of the Vickers Desiccator, designed to act as a short, wide heat exchanger. Many of these were fitted in order to uprate the short wet process kilns of the 1920s, and their characteristic shape remained a feature of many kilns long after their inefficient internals had been removed.

After WWII, larger wet process kilns began to be installed, and these fell into two camps: Vickers Armstrong supplied kilns with enlarged burning zones only, while FLS supplied mostly kilns with enlarged rear sections only, employing an identical design for the Long Dry kilns at Padeswood, Pitstone and Platin.

With the abandonment of wet process, most of these embellishments have disappeared. The larger Lepol kilns had short enlarged rear sections, although the smaller kilns were straight. Suspension preheater kilns are invariably short, straight cylinders, with minor conical constrictions at the inlet, and sometimes the outlet.

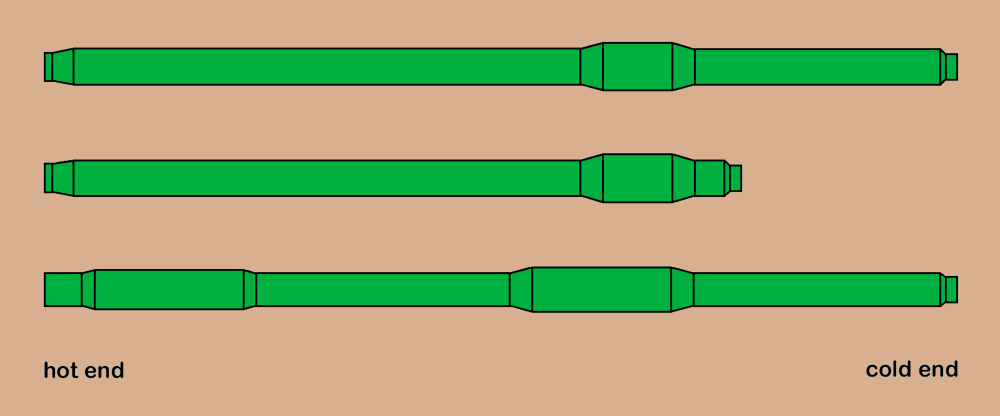

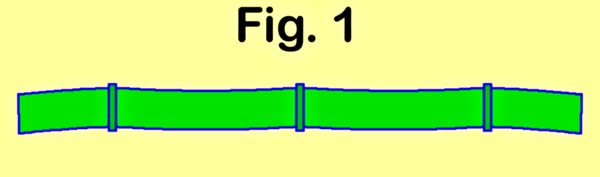

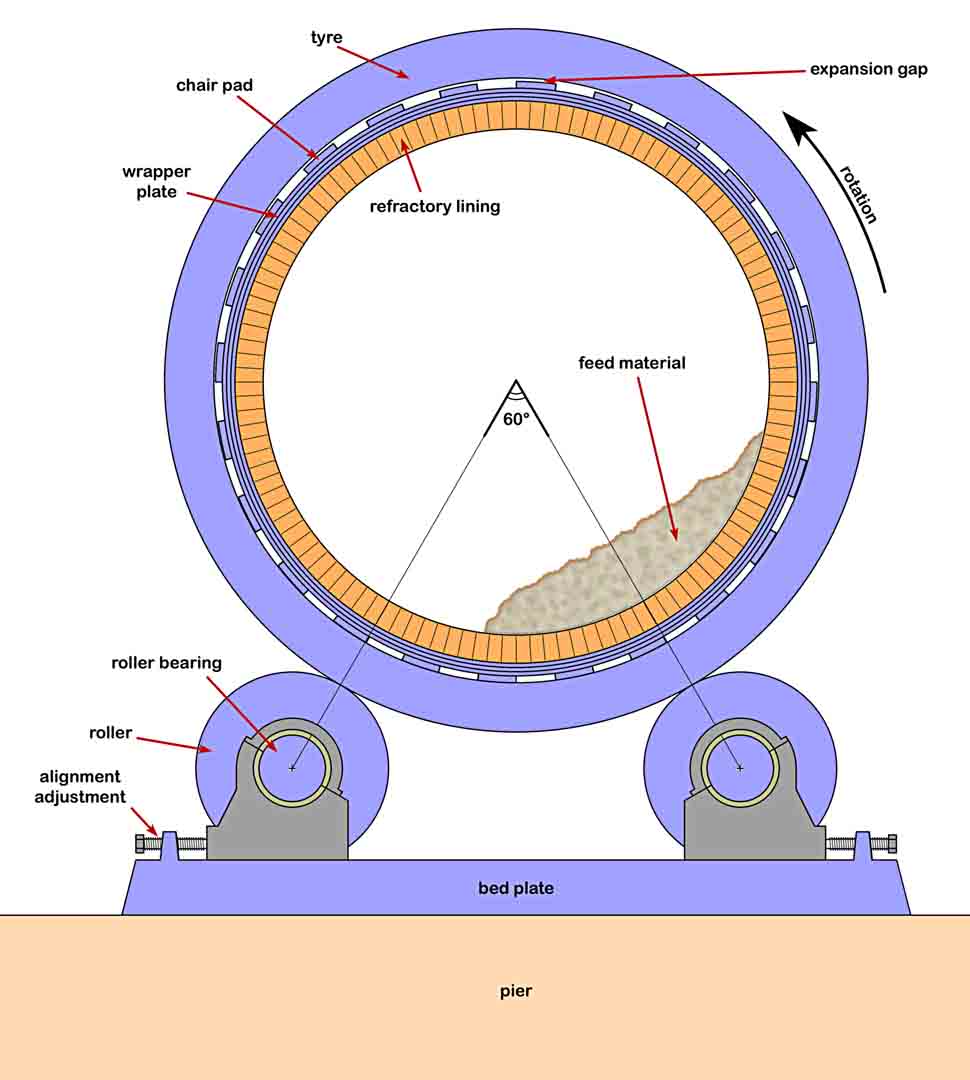

All rotary kilns essentially take the form of beams supported at a few points - the tyres (riding rings) - along their length, with the added complication that they rotate. The shell has to cope with all the forces involved, but is necessarily thin, since weight must be minimised. The design and maintenance of the kiln need to keep the distortion of the structure within acceptable limits. Flexure as the kiln rotates causes reduction in the life of the refractory lining (see below) as well as fatiguing the shell itself.

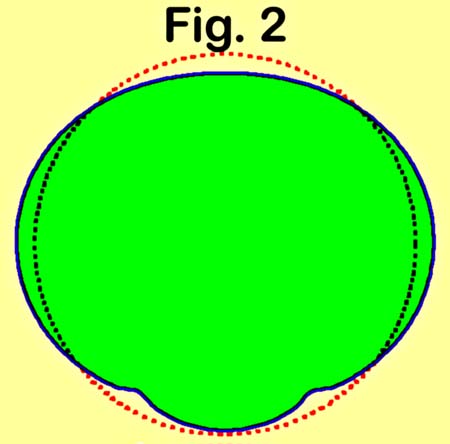

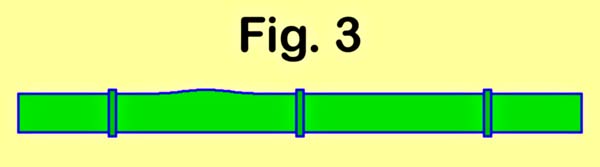

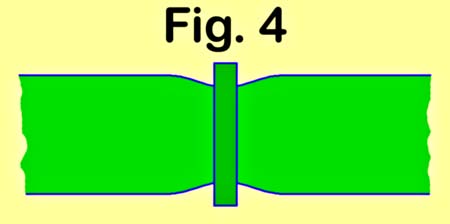

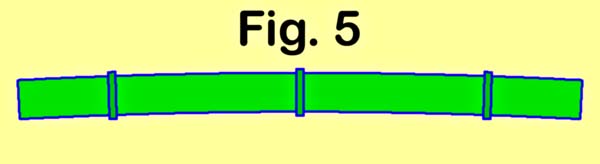

A number of different mechanical deformations occur. Diagrams show the nature of the distortion in an exaggerated form.

The axial and transverse distortions are the main concern: distortion due to damage and structural defects tend to amplify their effects.

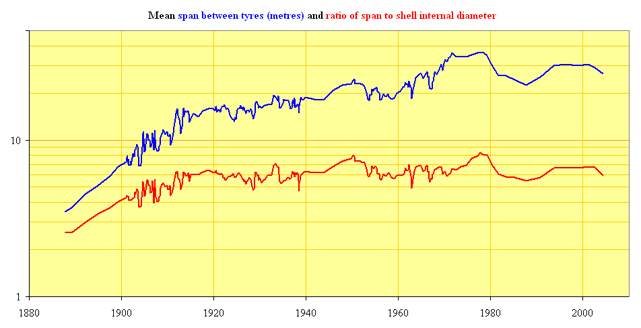

The axial flexure is greatest at the tyre, and increases with the span (relative to kiln diameter) between tyres. This is mitigated by extra layers (“wrappers”) of plate under the tyres.

Ovality affects both the tyre and the shell, but is much greater for the latter because of its thinness, and increases with the ratio of kiln diameter to shell thickness.

To protect the shell from the high temperatures of the feed and combustion gases, a brick lining is used. The early rotary kiln patents of Ransome, Stokes and Hurry & Seaman simply specified firebrick (although Stokes went so far as to require best firebrick). The 3’6” diameter Ransome kiln had brickwork 6” thick. In the case of the Ransome and Stokes kilns, because real clinkering temperatures were never achieved, the quality of the bricks was a moot point. As rotary kilns began to be used successfully in the USA, the maintenance of the lining became a major preoccupation.

Ordinary firebrick is made from aluminosilicate clays that are relatively free from contaminant elements, so that when fired they are largely a compound of silica and alumina, with the silica (at least in the cheaper grades) in considerable excess. Naturally, siliceous bricks are attacked by the highly basic clinker in the hottest parts of the kiln, and two strategies emerged in the first few years of kiln operation:

The bricks for cement kilns have to be made in a special tapered form in order to fit the curvature of the kiln shell. The iron and steel industries had prompted the production of refractories with a wide range of sophisticated chemistries, but it took some time for rotary cement production to increase to the stage at which these ideas were applied to cement kiln bricks. It was not until the 1920s that higher-alumina bricks became available in the UK, and manufacturers wanting to try them had to import them from the USA and Germany. Subsequently, other types of brick became available for the hotter parts of the kiln. Clearly, to avoid chemical attack, a basic brick is required, and bricks based on dolomite, magnesite and chromite became available.

An odd diversion from mainstream development in the early years was the use of "clinker" refractory. This was particularly favoured in Germany, and was fairly consistently recommended on kilns from German suppliers. Concrete made from graded clinker and portland cement was of course very much cheaper than purchased brick, but its life was usually very short, and its use mostly died out in the 1930s. It was last used at Masons in the late 1940s. It continued in use in the burning zones of the Anhydrite Process kilns.

With a wide variety of brick types to choose from, complex zoned bricking arrangements developed. Cheap siliceous brick was used in the coolest zones, grading up to higher alumina in the hotter parts, and the hottest parts were provided with basic brick, the type selected depending on the nature and thickness of coating produced by the local raw material. The selection of more sophisticated brick types was always a compromise between the enhanced brick-life expected and the greatly increased price per brick. From the 1980s, the use of chromite-containing bricks was phased out due to environmental regulations. By these strategies, the burning zone brickwork of wet process kilns in the post WWII period could be expected to last for a full year’s operation. Bricks in the cooler zones would usually last for many years or decades. A typical long-term-mean refractory consumption of a wet process kiln would be in the range 1-2 kg per tonne of clinker made, so the refractory was still a significant running cost.

With the advent of more efficient dry processes, and particularly precalciners, the relative cost of refractories has been reduced, mainly because of the larger output that can be obtained from a given sized kiln tube. Parallel with this is a reduction in the relative amount of heat wastage – “shell losses” – radiated from the surface of the kiln.

The desirable characteristics of refractories which must be achieved by careful selection are:

Factors tending to reduce refractory life include:

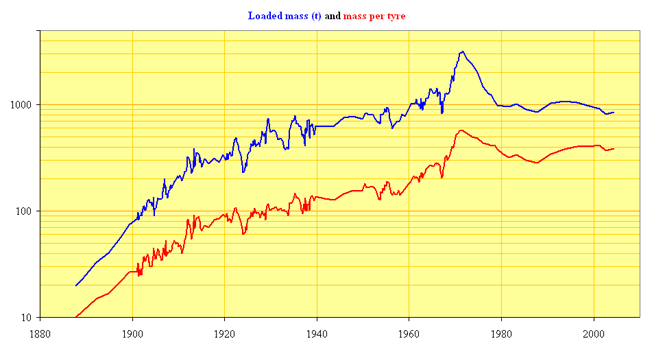

The purpose of tyres (often called riding rings) and rollers is to support the kiln and allow it to rotate with minimal friction. Rotary kilns are among the largest items of permanently moving industrial machinery, the largest examples weighing in their fully-loaded form several thousand tonnes. Despite the challenges of their size and their high temperature, the best examples of rotary kiln rotate on their rollers almost frictionlessly, the power supplied by the drive being almost entirely in order to oppose the eccentric load of the contents of the kiln. On cutting the power to a kiln, the kiln will “roll back” and unless a brake is applied, will continue to swing like a pendulum for ten or fifteen minutes before coming to a standstill. This finely-tuned mechanical condition requires sophisticated design of the kiln’s supports.

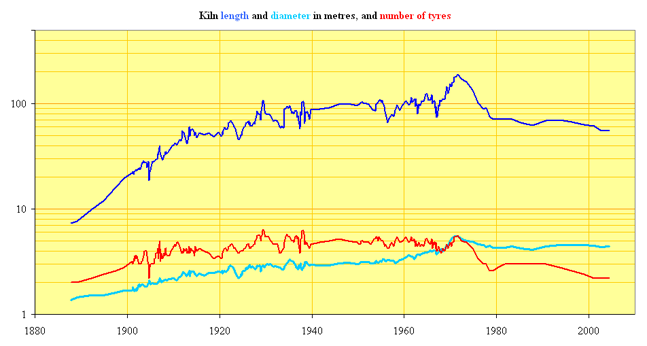

A standardised design evolved during the first three decades of the twentieth century, allowing the great escalation in size of kilns that then followed.

The tyre itself is usually a single steel casting, machined to accurately circular dimensions and with a mirror-smooth texture on all surfaces. Early tyres were occasionally produced as half-sections that could be easily assembled and replaced, but this was very soon abandoned because of the resulting rapid and erratic wear at the joints.

In the standard design, the tyre was mounted loosely on the kiln shell. Inevitably, the tyre is cooler than the kiln shell, and so a small gap allows differential expansion to take place. The gap is usually designed to be about 0.2% of shell diameter at normal operating temperature. The kiln tube bears down upon the inside of the tyre through smooth-surfaced chairs which also have lugs bracketing the tyre, preventing it from slipping along the kiln axially. The spacing of the chairs also reduces the amount of heat conduction from the kiln shell to the tyre. The tyre needs to remain relatively cool because so large a casting would be unlikely to survive a large radial temperature differential during heating up of the kiln. Another effect of the gap is that tyres would gradually precess around the kiln, with one complete turn in every 500 turns of the kiln. Measuring the rate of precession was a rough-and-ready way of assessing the width of the expansion gap while the kiln was in operation. Small changes due to wear could be adjusted by adding shims.

The expansion gap leads to distortion as discussed above, with the shell sagging within the loose fit of the tyre, which causes the refractories to flex and break. If the kiln becomes sufficiently over-hot to close up the expansion gap, then permanent damage to the shell occurs. The early kilns had the chairs attached directly to the shell, and damage to the shell and refractories in this area soon led to the provision of one or two extra layers of shell plate - "wrapper plate" - in the tyre area. From the 1920s, all kilns had triple-thickness shell under the tyre chairs, and this made ovality problems manageable until kilns over 5 m in diameter started to be constructed.. The largest diameter British kilns at Northfleet (where the burning zone internal diameter was 6.096 m) suffered major difficulties with short refractory life. Since scale-up of modern precalciner kilns requires the use of large diameters, “splined tyres” have been developed since the 1990s (although these are occasionally encountered in more primitive form before that). These allow the tyre to interlock with the shell (while maintaining an air gap) in such a way that the kiln is suspended from the “3 o’clock” and “9 o’clock” positions rather than have the weight of the kiln entirely concentrated at the “6 o’clock” position as in the traditional design. This has the effect of reducing the magnitude of ovality distortion by 75% or more, although the resulting design is much more complex and therefore expensive. This expense is easily offset by savings in refractory costs, and all recent kiln installations have used this new design.

The basic design of rollers has changed little over the years. The rollers are mounted on a massive cast iron or steel base plate which provides the inward horizontal forces on the rollers and distributes the weight of the kiln over the pier. The spacing between the rollers has to be small enough to prevent large horizontal forces, but large enough to keep the kiln laterally stable. Rollers are designed to subtend 60° at the tyre centre, and this seems always to have been the case. Minor adjustment is allowed so that the kiln can be kept aligned (i.e. to keep the centres of the tyres co-linear) as small changes take place, such as wear of the tyre or settlement of the pier. The roller outer face is made wider than that of the tyre, mainly to allow for contraction of the kiln during shut-down. This poses a problem: if the tyre remains in one position relative to the roller, wear or plastic deformation causes a depression to form on the roller face. It is therefore normal practice to deliberately make the kiln “float” (i.e. regularly move uphill and downhill across the rollers) so that wear is evened out. Because the kiln slopes (typically 1.5° to 3.5°) it has a natural tendency to slip downhill as it turns. From the earliest times, this tendency was compensated by “cutting” the rollers – skewing their axes by a very small angle so that an uphill screw action is imparted to the tyre. This action relies upon the friction between the tyre and roller surfaces, and operators could therefore make the kiln move up or down by adjusting the amount of friction. As a further precaution to prevent the kiln from falling off its rollers, thrust rollers bearing upon the side of the tyre are used. These are usually located on the roller beds nearest the drive, where movement most needs to be restricted.

Relying upon friction, “cutting” of rollers necessarily increased the rate of wear, and after being standard practice for many years, it was abandoned from the 1950s onward in favour of the use of mechanical thrusters to float the kiln. These usually take the form of hydraulic rams attached to the thrust rollers, which are automatically controlled to impart a saw-tooth axial oscillation to the position of the kiln, with an amplitude of a few centimetres.

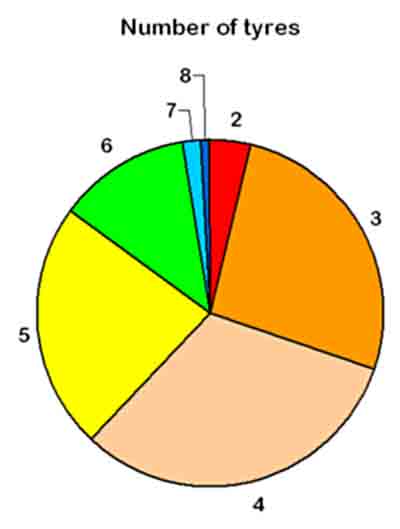

As mentioned above, a rotary kiln is essentially a rotating beam, so its tendency to sag between the supports means that the distance between the supports must be limited, and longer kilns must therefore have more tyres.

The earliest kilns had only two supports, so that there was no need to confront the problem of kiln alignment. In fact, during the early 1890s, the prospect of these problems was a disincentive to building kilns over 30 ft long. But the new patent kilns of the late 1890s were extended to 60 ft with three tyres. The question of whether it was feasible to progress to longer kilns was settled with Edison's kilns of 1905. These 150 ft kilns bizarrely had one tyre on each of their 10 ft cast iron sections - a total of 15 tyres. These kilns were an evolutionary dead end, but at least demonstrated that there need be no limit to the length of kilns.

Three kilns had eight tyres: West Thurrock kiln 6, Westbury kiln 2 and Masons kiln 5. Note: planetary cooler outrigger tyres not included.

Since the amount of sag between supports depends on the ratio of the span to the diameter, the actual number of tyres employed depends upon the kiln's length/diameter ratio, but also upon the load that could be accommodated by the tyre/roller systems of the time. The ratio of between-tyre span to kiln diameter settled down to a mean value of about 6. The total mass of wet process kilns increased in proportion with their output, and kilns were designed with as many as eight tyres. The emergence of dry process kilns brought about a return to the use of short kilns with three tyres. The following charts show the evolution of these factors with time, as running mean of five.

|

|

|

The most recent precalciner kilns, because most of the processing is done in the preheater, can have very low length/diameter ratios (<14) and this re-introduces the possibility of mechanically simplified two-tyre kilns. Splined tyres are combined with self-aligning roller assemblies and through-the-roller drives (see below), allowing the system to continue to function even if the kiln is bent. This has been adopted for the kilns at Rugby, Ballyconnell, Kinnegad, Tunstead and Platin.

If a kiln has length 14D and has two tyres located at 25% and 75% of the length, then the span between the tyres is 7D, which is about the practicable limit. The Kinnegad kiln has a girth-gear drive.

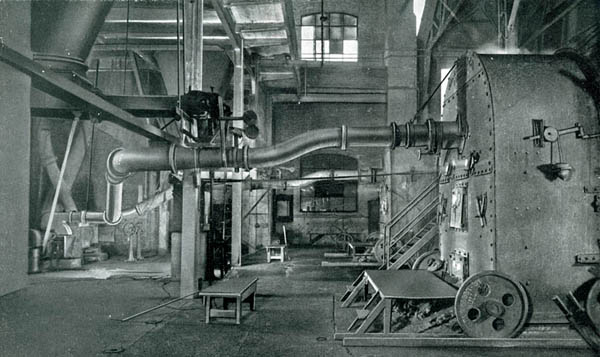

Ever since the first Ransome kiln (until recently) rotary kilns were turned by means of a single girth gear (known as the turning gear) surrounding the kiln. The early kilns turned very slowly, the girth gear meshing with a worm gear. Subsequently full-speed rotation of kilns in the range 0.5-1.5 rpm became standard, and the gear meshed with a pinion running at 10-20 rpm. The pinion shaft was driven by a gearbox. Some kiln gearboxes derived their power from layshafts driven by a common electric motor or a steam engine, but this was comparatively uncommon in Britain, and most kilns had their own dedicated electric motor. In many older plants, rotary kiln drives represented the first use of electricity for anything other than lighting.

Picture: ©NERC: British Geological Survey Cat. No. P539361. Drive of Plymstock Kiln 1 (constructed 1961). As is normal with short, dry process kilns, the drive is close to the rear - the back end seal is visible top right. The girth gear is placed close to a tyre for stability, and axial movement is restricted by a horizontal thrust roller, visible under the kiln. The drive pinion is behind the left hand roller. Behind that is the gearbox, and the 67 kW electric motor is in the rectangular enclosure on the left edge. The roller bearings, gearbox and motor all have heat shields to protect them from radiant heat from the kiln shell. From the position of the girth gear tangent plates, it can be seen that the kiln turns clockwise when viewed from this direction, and the drive pinion, as is normal, is on the "rising" side of the kiln, under the feed.

Picture: ©NERC: British Geological Survey Cat. No. P539361. Drive of Plymstock Kiln 1 (constructed 1961). As is normal with short, dry process kilns, the drive is close to the rear - the back end seal is visible top right. The girth gear is placed close to a tyre for stability, and axial movement is restricted by a horizontal thrust roller, visible under the kiln. The drive pinion is behind the left hand roller. Behind that is the gearbox, and the 67 kW electric motor is in the rectangular enclosure on the left edge. The roller bearings, gearbox and motor all have heat shields to protect them from radiant heat from the kiln shell. From the position of the girth gear tangent plates, it can be seen that the kiln turns clockwise when viewed from this direction, and the drive pinion, as is normal, is on the "rising" side of the kiln, under the feed.

Picture: ©Rugby Archive: Cat. No. RC-10. Helical girth gear on Rochester Kiln 6 during construction (1978). The drive was on the enlarged (5.3 m) back end section of the kiln, making this one of the larger girth gears. Because of the high power requirement (580 kW?), this is a dual drive. The rising-side pinion is shown: the other is off-frame to the left, and the other gear-box is just visible through the hole in the girth gear.

Picture: ©Rugby Archive: Cat. No. RC-10. Helical girth gear on Rochester Kiln 6 during construction (1978). The drive was on the enlarged (5.3 m) back end section of the kiln, making this one of the larger girth gears. Because of the high power requirement (580 kW?), this is a dual drive. The rising-side pinion is shown: the other is off-frame to the left, and the other gear-box is just visible through the hole in the girth gear.

Until the advent of frictional drives (see below), kilns only ever had one turning gear and this supplies all the torque to turn the kiln, so in the case of a long kiln, it is usually positioned somewhere near the middle (strictly speaking, the centre of mass) to minimise the amount of torsional distortion produced in the shell. Preferably a relatively cool section of the kiln is chosen. The gear is placed near to a tyre so that it is accurately aligned with the kiln axis, with minimal wobble. It is normal for the nearby tyre to be fixed in position with thrust rollers, so that as the kiln expands on warming up, the turning gear position remains fairly constant, while the nose and tail of the kiln expand outward. The pier of the nearby tyre is usually extended to include the pinion mounting bed, the gearbox and the motor, although on early kilns it was common to mount the motor on the kiln house floor, and connect it to the gearbox with a flat belt. In the case of shorter dry process kilns with preheaters, it has been normal practice to locate the turning gear next to the rear tyre, at the coolest part of the kiln.

Early turning gears were attached directly to the shell. Differential expansion in such circumstances causes the gear to break and the kiln shell to "neck", and this practice was soon abandoned in favour of some sort of flexible mounting. Various mountings have been used, but by far the most common is the tangential mounting, which emerged in the first decade of the twentieth century. Flexible plates are riveted (and later welded) to the kiln shell tangentially, the other end being fixed to the gear ring through a flexible coupling. This allows expansion of the shell to take place unfettered. It also results in minimal heat transfer to the gear ring, so that the latter remains cool enough for conventional lubricants to be used. Tangent plates must operate in tension, and so they differ from longitudinal mountings in that the kiln may not be run in reverse.

There is an urban legend that, when the first kiln at Westbury was commissioned, the chains were hung in the wrong direction, screwing the feed uphill instead of downhill. Rather than delay the Grand Opening, the polarities of the motors were reversed, and the kiln was run backwards until the dignitaries had departed.

Until the 1960s, kilns had a single pinion engaging with the gear wheel. These were almost invariably located on the rising side of the kiln. This places it underneath the feed bed, which is marginally cooler than the other side which is in contact with hot combustion gases. It also places the turning effect closest to the source of the eccentric load. The rotation of the kiln lifts the feed up the side of the kiln, and the energy required to maintain its centre of gravity above the lowest (6 o'clock) point is the main component (80-90%) of the energy consumed. In the case of kilns containing curtain chains, these also produce an eccentric load.

Rotary kilns have always had variable speed drives. From the earliest times there was always, at least, an option of "full speed" and "half speed". This allows the operator to vary the rate at which the feed advances down the kiln, and in particular, allows the kiln to be warmed back up again if for some reason the burning zone has become too cold to sinter the clinker. On early drives, speed change was brought about by use of "fast and loose" pulleys of various sizes. However, with DC motors it was also possible to vary the speed of the motor itself, and this ability was one of the main reasons for the early adoption of electric power. However, variable speed was not viable for more powerful motors, so this placed a limit on the size of kiln that could be turned with a single motor, the maximum being around 250 kW.

An alternative strategy for larger kilns is to have two pinions acting on the gear wheel, one on each side of the kiln. This was problematic for earlier technology, because of the problems of having two motors competing to supply torque at varying speed, but from the 1960s, advances in motor control allowed dual drives to be installed on larger kilns. Because it is related to eccentric load, kiln rotating power is more or less proportional to speed. The need for higher rates of rotation began to emerge with suspension preheater kilns in the 1960s, and much higher speeds of 4 rpm or more are required for short precalciner kilns. Modern drives, in line with the large, high speed kilns being installed, can be much larger (>500 kW from each motor in a dual drive), with speed varied over a wide range by means of solid state controls. However, the largest British drives appear to have been the pair of 580 kW motors on each of the six kilns at Northfleet

An additional feature of kilns from the 1950s onward was the provision of an "auxiliary drive" which is engaged in the event of failure of the main drive. Once a kiln has been raised to operating temperature, it must be kept turning, at least intermittently, because the upper part cools faster than the lower part which contains the hot feed bed. If this situation continues, differential contraction will cause the kiln to bend. A further problem is that, at the hot end of the kiln the feed is partly liquid, and will "freeze" into a solid block unless turned over by kiln rotation. Frozen feed, on finally turning the kiln, will pull out the underlying refractory lining. The earliest "barring gear" on smaller kilns consisted simply of a highly geared-down capstan that could be turned by hand. More modern systems commonly consist of a small diesel engine that can be started up and engaged with the gear-box, even if there has been a complete power failure, turning the kiln at about 0.2 rpm.

With the re-emergence of two-tyre kilns on precalciner systems, some kilns have been supplied without girth gears, the torque being supplied through the rollers. This relies upon the friction between roller and tyre, and the critical requirement is that the friction should be sufficient to start a heavily-loaded kiln from the stalled condition. On older kilns, this was never a viable proposition, but the large-diameter two-tyre kilns have a sufficiently large roller loading that tangential friction is greatly in excess of the likely requirements. Drive through the tyres serves further to simplify the design of two-tyre kilns. Torque is applied to the roller shaft(s) by either an electric motor and gearbox or by a hydraulic drive.

Picture: from article in The Engineer: Norman Kiln A1 hood viewed westwards in 1904. Typical Fellner & Ziegler hood design. Note the firing pipe entering below and to the right of the kiln centre-line towards the clinker bed - the kiln turns anti-clockwise. Early short kilns had difficulty concentrating the heat into the burning zone. The clinker fell into a rotary cooler below the firing floor. The cooler air was used in coal drying, and little entered the kiln directly.

Picture: from article in The Engineer: Norman Kiln A1 hood viewed westwards in 1904. Typical Fellner & Ziegler hood design. Note the firing pipe entering below and to the right of the kiln centre-line towards the clinker bed - the kiln turns anti-clockwise. Early short kilns had difficulty concentrating the heat into the burning zone. The clinker fell into a rotary cooler below the firing floor. The cooler air was used in coal drying, and little entered the kiln directly.

Hood of Wilmington Kiln 4 from the south in 1921. Typical FLS design of the time with a concentric cooler below the kiln.

Hood of Wilmington Kiln 4 from the south in 1921. Typical FLS design of the time with a concentric cooler below the kiln.

Picture: ©NERC: British Geological Survey Cat. No. P539367. Hood of Plymstock Kiln 1 (constructed 1961): a larger, fixed hood. The kiln rotates anticlockwise, so the feed bed is on the right hand side of the kiln. The operator is viewing the feed diagonally from the left, under the flame, in order to get a long perspective view. Note the oil-fed burner. Below is a Fuller grate cooler.

Picture: ©NERC: British Geological Survey Cat. No. P539367. Hood of Plymstock Kiln 1 (constructed 1961): a larger, fixed hood. The kiln rotates anticlockwise, so the feed bed is on the right hand side of the kiln. The operator is viewing the feed diagonally from the left, under the flame, in order to get a long perspective view. Note the oil-fed burner. Below is a Fuller grate cooler.

The purpose of the kiln hood is

The last of these would today be considered to be the most important requirement, but in the early days the importance of secondary air was not always appreciated, and some (including Lathbury and Spackman) maintained that all combustion air should enter through the firing pipe. For this reason, early kiln hoods were usually very short, and communicated with a small, restrictive cooler throat.

The hood receives direct radiant heat from the white-hot clinker and refractories and the flame, and so is refractory lined for protection from this. It also needs to be strongly constructed to cope with pressure variations that may occur. On the other hand, there is a need to gain access to the kiln for maintenance of the refractories. This was particularly the case during the experimental first decade of the twentieth century, when the service life of refractories was often very short. For this reason, from the first patents onward, the kiln hood was mounted on wheels or rollers so that it could be rolled back from the kiln nose. The need to do this later became a reason for restricting the size and cross-section of kiln hoods.

A significant step-change in hood design came with the Fuller grate cooler patent, which put heavy emphasis on the speed of cooling of the clinker and the aerodynamics of the secondary air. This led to the installation of deeper hoods, and the escalation of both hood depth and kiln diameter led to the abandonment of moveable hoods in the early 1960s. Modern large hoods have doors in the front large enough for small vehicles to enter the kiln.

For maximum thermal efficiency, modern kilns use a relatively small amount of cool primary air through the firing pipe, and coolers produce secondary air at high temperature, so hoods are carefully aerodynamically designed to ensure that the secondary air envelopes the flame in a manner that optimises combustion.

The use of the hood as a view-point for the operator was essential in early practice. The peak temperature of the feed in the front of the kiln is critically important, since a fall in temperature causes the free-lime content to rise rapidly, and clinkering (i.e. sintering) may cease altogether, causing fine unburned feed to rush forward into the cooler. On the other hand, too high a temperature is liable to cause loss of coating and damage to the kiln. Although various kinds of pyrometer for temperature measurement have been available throughout the history of rotary kilns, it can be safely said that they were not an effective means of control until the end of the twentieth century: all methods are optical, and instrumental methods are defeated by the difficulty of discriminating between radiation from the various sources - clinker, flame, brickwork and swirling dust. The sole control of temperature was therefore the expert eye of the operator. Visible criteria were the colour and brightness of the clinker, the height to which the clinker climbs the rotating kiln wall (which is related to the stickiness caused by the amount of liquid formed) and the positions where clinkering starts and finishes. The control panels were therefore located on the firing floor and the operator interspersed scrutiny of the instruments with frequent visits to the kiln hoods to monitor progress. Cement plants stood or fell by the round-the-clock expertise of their kiln operators.

From the late 1960s, instrumentation started to improve, and the operator’s reliance on visual information was aided by TV cameras mounted on the hood inspection ports. This led to the possibility of centralised control rooms remote from the kiln. More modern cameras are provided with infra-red sensitivity and the image is processed to show colour-coded temperature. Modern firing floors are usually deserted unless something has gone wrong.

The seals connect the ends of the kiln to the kiln hood and the kiln exhaust duct. They prevent leakage of cold air into the system at these points. Gases are moved through the kiln by the suction provided by a fan in the exhaust or in the preheater, so the efficiency of the fan relies upon minimal inleak at the back end seal. Furthermore, even if the fan is capable of handling a large amount of inleaking air, the dust control equipment and the preheater (if present) will be inefficient if they have to handle an excessive amount of gas. The front-end seal ensures that there is sufficient suction to draw the secondary air from the cooler into the kiln.

Both these seals have to deal with high temperatures, and so must be either of a simple heat-proof design, or must be kept cool by means of external fans. Both must also be capable of remaining air-tight as the kiln expands and contracts, and must cope with rotation of a kiln that may be slightly distorted.