A detail plan of the plant has been partially completed, but further progress is prevented by lack of information on the layout of kilns 3, 4 and 5.

Approximate capacity: tonnes per year: ✄

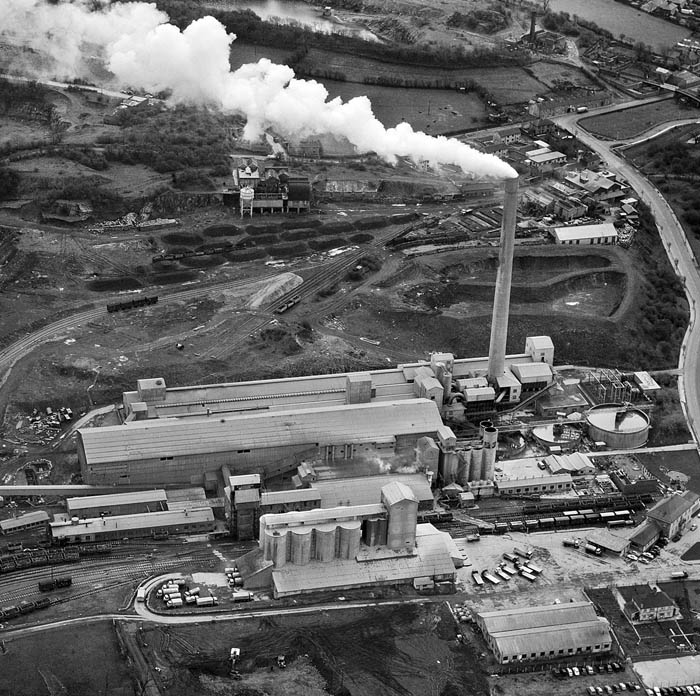

Picture: ©Historic England - NMR Aerofilms Collection. Catalogue number A110850. A high-definition version can be obtained from Historic England. This was taken on 29/4/1963, viewed from the NNW. The plant at this stage had four wet process kilns. The longest kiln, furthest away, is kiln 4, extending beyond the stack. The subsequent longer kilns 5 and 6 had a separate stack. In front of the kilns is the long clinker and coal store, and in front of that the raw and finish mills. To the right of these are slurry blending silos and the three slurry storage tanks. In the foreground are the cement silos.

Picture: ©Historic England - NMR Aerofilms Collection. Catalogue number A110850. A high-definition version can be obtained from Historic England. This was taken on 29/4/1963, viewed from the NNW. The plant at this stage had four wet process kilns. The longest kiln, furthest away, is kiln 4, extending beyond the stack. The subsequent longer kilns 5 and 6 had a separate stack. In front of the kilns is the long clinker and coal store, and in front of that the raw and finish mills. To the right of these are slurry blending silos and the three slurry storage tanks. In the foreground are the cement silos.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The preserved drive section of Kiln 6, viewed downhill (from the west). The kiln turns clockwise when viewed from this direction. This shows the two drive shafts with, the spur-ring and the fourth tyre beyond. This is a 4.35 m ID section, with 100 mm thick brickwork in this relatively cool part of the kiln.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The preserved drive section of Kiln 6, viewed downhill (from the west). The kiln turns clockwise when viewed from this direction. This shows the two drive shafts with, the spur-ring and the fourth tyre beyond. This is a 4.35 m ID section, with 100 mm thick brickwork in this relatively cool part of the kiln.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The Pfeiffer rawmill on Kiln 7 line. The 1900 kW drive motor is bottom right. The ground rawmix, suspended in hot gases, leaves through the duct on top.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The Pfeiffer rawmill on Kiln 7 line. The 1900 kW drive motor is bottom right. The ground rawmix, suspended in hot gases, leaves through the duct on top.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The front end of Kiln 7, and the cooler. The cooler fans are behind the fencing. The extended hood and tertiary air duct are top left.

Picture: ©Alan Murray-Rust 2015 (modified), and licensed for reuse under this Creative Commons Licence. See this and related images on Geograph. The front end of Kiln 7, and the cooler. The cooler fans are behind the fencing. The extended hood and tertiary air duct are top left.

Early Ribblesdale Castle Brand. The image of Clitheroe Castle eventually gave its name to the Castle Cement group.

Location:

- Grid reference: SD74894365

- x=374890

- y=443650

- 53°53'18"N; 2°22'55"W

- Civil Parish: Clitheroe, Lancashire

Clinker manufacture operational: 1936 to date

Approximate clinker production to 2022: 59 million tonnes (4th)

Raw materials: Argillaceous Carboniferous Limestone (Chatburn Limestone Formation: 348-352 Ma), with varying amounts of intercalated shale from quarry at 375900,443900. In the early days some superficial clay was also used. The more recently used Bellmanpark quarry yields high-grade Knoll Reef limestone.

Ownership:

- 1936-1986 Ribblesdale Cement Ltd (50% Tunnel, 50% Thomas W Ward until 1981, then by Rio Tinto Zinc [RTZ])

- 1986-2009 Castle Cement Ltd (RTZ to 1989, Scancem to 1999, HeidelbergCement to 2009)

- 2009 to date Hanson Cement UK (HeidelbergCement)

Alternatively called Clitheroe, but not to be confused with the other small plants that operated in the town. The Isis plant was at 375000,443600, on the site of the current new circular clinker store.

FLS were interested in developing a plant in the under-served north-west of England, and the closure of the Isis plant prompted them to investigate the Clitheroe site. A new nominally independent company was created in order to create new sales quota under the rules of the then-existing cartel. However, it functioned as “sister” plant to Ketton, and the Ribblesdale, Ketton and Tunnel companies were operated in a co-operative manner. As early as 1947, the fforde Report regarded the incipient “Castle Cement” as a distinct industry group.

Although the materials were eminently suitable for dry process manufacture, this was not an option offered by FLS when the plant started. Nevertheless, the successive wet process kilns were from the outset relatively efficient, the Ribble valley materials producing low moisture content slurries with ease.

The plant continued to ignore the dry process options by then being taken up at Cauldon and Plymstock with its kiln 4 in 1961, and the plant had the distinction of installing Britain’s last wet process kiln (kiln 6) in 1976, when many wet process kilns were being de-commissioned due to the energy crisis. The plant made sulfate resisting clinker alongside ordinary clinker from 1955? to 1997.

A dramatic leap forward in efficiency came with the installation of kiln 7, which was Britain’s first air-separate precalciner kiln. At this point the plant with five operating wet kilns was Britain’s largest, but wet kiln capacity was subsequently shed, and HeidelbergCement’s “no wet kilns” policy led to the shut-down of kilns 5 and 6 when Padeswood’s kiln 4 was up and running in 2005.

The plant, in addition to a reasonable local market in north Lancashire, had good rail communications, allowing access to West Yorkshire, and a 30 km trip to the West Coast main line. The expansion of the plant was predicated largely on the latter, and the plant fed the Clydebank and Gartsherrie grinding plants in Scotland. Standard gauge rail was also used in the quarry until 1967, when it was replaced with dumpers.

Please contact me with any relevant information or corrections. I am particularly interested in firmer dates and statistics.

Note: technical information on currently operational plants is ✄withheld in the public version of the site at present, except where already published (see references).

Power supply

The plant was entirely electrically powered from the grid from the outset.

Rawmills

- Initially some superficial clay was used, slurried in a washmill: ball mills – one per kiln – inter-ground this slurry with limestone at the plant.

- Rawmills 1&2 1936-1961 634 kW Unidan 2.4 × 11.0 m ball mills(3)

- Rawmill 3 1951-1961 634 kW Unidan 2.4 × 11.0 m ball mill(2)

- 1961-2005 rawmills replaced with three 1120 kW Unidan 2.9 × 12.0 m ball mills: old rawmills converted to cement milling(3)

- Rawmill 4 1967-2005 1120 kW Unidan 2.9 × 12.0 m ball mills(4)

- Rawmill 5 1991-2005 Unidan ball mill size? transferred from Ketton(5)

- Kiln 7 has a 1900 kW Pfeiffer roller mill using kiln exhaust gas for raw material drying(6).

Seven rotary kilns were installed.

Kiln A1

Supplier: FLS

Operated: ?/11/1936(7)-1982

Process: Wet

Location: Hot end 374870,443697: Cold end 374799,443640: entirely enclosed

Dimensions: Metric 91.20 × 3.000B / 2.400CD(1)

Rotation (viewed from firing end): anti-clockwise(8).

Slope: ?

Speed: ?

Drive: ?

Kiln profile 0×3000: 37200×3000: 39450×2400: 91200×2400: Tyres at 6000, 17400, 33600, 49575, 65325, 83325: turning gear at 51825(9)

Cooler: FLS bucket grate(10)

Fuel: coal

Coal mill: indirect: mill?

Exhaust: initially via dry drop-out box and ID fan direct to stack. An electrostatic precipitator was put in after the ID fan in 1961(13).

Typical Output: 1936-1960 228 t/d: 1961-1970 240 t/d: 1971-1982 184 t/d

Typical Heat Consumption: 1936-1956 6.76 MJ/kg: 1957-1960 6.33 MJ/kg: 1961-1967 5.64 MJ/kg: 1968-1975 5.65 MJ/kg: 1976-1982 5.73 MJ/kg

Kiln A2

Operated: 10/9/1937(11)-1983

Location: Hot end 374875,443691: Cold end 374804,443634: entirely enclosed

Identical in all other respects to A1

Kiln A3

Supplier: FLS

Operated: 17/07/1951(12)-1983

Process: Wet

Location: Hot end (cooler ports) 374883,443686: Cold end 374806,443625: entirely enclosed

Dimensions (from cooler ports: metric):

- 1951-1969: 92.00 × 3.000(2)

- 1969-1983: 98.00 × 3.000BC / 3.450D(1)

Rotation (viewed from firing end): ?

Slope: ?

Speed: ?

Drive: ?

Kiln profile: ✄

Cooler: Unax planetary 10 × 6.30 × 1.200

Fuel: coal

Coal mill: indirect: 120 kW Tirax 1.6 × (3.2 + 3.2) m ball mill(2)

Exhaust: ID fan initially direct to stack. Electrostatic precipitator installed after fan 1961(13).

Typical Output: 1951-1960 367 t/d: 1961-1970 385 t/d: 1971-1983 296 t/d

Typical Heat Consumption: 1951-1956 6.91 MJ/kg: 1957-1960 6.73 MJ/kg: 1961-1967 5.76 MJ/kg: 1968-1975 5.68 MJ/kg: 1976-1983 5.93 MJ/kg

Kiln A4

Supplier: FLS

Operated: 05/1961(14)-1992

Process: Wet

Location: Hot end (cooler ports) 374886,443675: Cold end 374781,443590: entirely enclosed

Dimensions (from cooler ports): Metric 145.00 × 3.300BC / 3.600D(3)

Rotation (viewed from firing end): ?

Slope: ?

Speed: ?

Drive: ?

Kiln profile (from cooler ports): ✄

Cooler: Unax planetary 10 × 11.50 × 1.400

Fuel: coal, from 1985 replaced with up to 25% petcoke.

Coal mill: indirect: 205 kW Tirax 2.3 × (4.8 + 2.8) m ball mill(3)

Exhaust: ID fan followed by electrostatic precipitator then to stack.

Typical Output: 1961-1970 545 t/d: 1971-1992 528 t/d

Typical Heat Consumption: 1961-1967 5.41 MJ/kg: 1968-1975 5.43 MJ/kg: 1976-1982 5.66 MJ/kg: 1983-1992 5.81 MJ/kg

Kiln A5

Supplier: FLS

Operated: 10/1967(15)-2005

Process: Wet

Location: Hot end (cooler ports) 374897,443659: Cold end 374776,443562: entirely enclosed

Dimensions (from cooler ports): Metric 155.00 × 4.150BC / 4.350D(4)

Rotation (viewed from firing end): ?

Slope: ?

Speed: ?

Drive: 2 × 150 kW(4)

Kiln profile (from cooler ports): ✄

Cooler: Unax planetary 10 × 12.00 × 1.650

Fuel: coal, from 1985 replaced with up to 15% petcoke, supplemented by liquid wastes from 1993.

Coal mill: indirect: 205 kW Tirax 2.3 × (4.8 + 2.8) m ball mill(4)

Exhaust: ID fan followed by electrostatic precipitator then to stack.

Typical Output: 1967-1975 912 t/d: 1976-1982 930 t/d: 1983-2005 955 t/d

Typical Heat Consumption: 1967-1975 5.40 MJ/kg: 1976-1982 5.46 MJ/kg: 1983-2005 5.59 MJ/kg

Kiln A6

Supplier: FLS

Operated: 1976(16) to 2005

Process: Wet

Location: Hot end (cooler ports) 374915,443634: Cold end 374790,443534: unenclosed

Dimensions (from cooler ports): Metric 160.00 × 4.350BC / 5.000D(1)

Rotation (viewed from firing end): anti-clockwise(17).

Slope: ?

Speed: ?

Drive: dual motors: ? kW(17)

Kiln profile (from cooler ports): ✄

Cooler: Unax planetary 11 × 12.00 × 1.650

Fuel: coal, from 1985 replaced with up to 15% petcoke, supplemented by liquid wastes from 1993.

Coal mill: ?

Exhaust: ID fan followed by electrostatic precipitator then to stack.

Typical Output: 1976-1981 960 t/d: 1982-1992 1020 t/d: 1993-2005 1070 t/d

Typical Heat Consumption: 1976-1981 5.52 MJ/kg: 1982-2005 5.62 MJ/kg

Kiln A7

Supplier: FLS

Operated: 1983 to date

Process: air-separate precalciner: details ✄

Location: hot end 375015,443680: cold end 375041,443628: unenclosed

Dimensions: Metric 58.00 × 4.150(1)

Rotation (viewed from firing end): anti-clockwise(18).

Slope: ?

Speed: ?

Drive: ?

Kiln profile: ✄

Cooler: grate: details ✄

Fuel: coal, petcoke, waste liquids from 1992(19), tyres from 2003(20) and meat and bone meal from 2007.

Coal mill: ✄

Exhaust: ✄

Typical Output: ✄

Typical Heat Consumption: ✄

References:

- (1) Jackson p 294

- (2) Ketton Archive DE2627/289

- (3) Ketton Archive DE2627/291

- (4) Ketton Archive DE2627/292

- (5) del Strother p 85

- (6) Jackson & contractor website

- (7) Recorded but not known to me: said to be "last month" in 1st annual report 21/12/1936

- (8) photo of turning gear

- (9) estimated from photograph

- (10) photo of hood

- (11) Times 1/10/1937 p 25

- (12) del Strother p 75

- (13) del Strother, p 66

- (14) del Strother, p 82 - day not given

- (15) del Strother, p 86 - day not given

- (16) date recorded but not known to me

- (17) existing kiln remnant picture

- (18) video

- (19) del Strother p 94

- (20) Environment Agency 2009 report, p 7

Sources:

- Primary Sources:

- Ketton papers, Leicestershire, Leicester & Rutland Record Office

- Peter del Strother, History of Ribblesdale Cement, Castle Cement Ltd, 2008, ISBN 978-0-9545416-1-3

- Ordnance Survey 1:2500 mapping

- BGS mapping and monographs

- Confirmatory Sources: