Highly conjectural layout based upon the map and the pictures below. If there were kilns, they might have been arranged thus.

Highly conjectural layout based upon the map and the pictures below. If there were kilns, they might have been arranged thus.

This was taken around 1935, viewed from the south. The long open-sided building to the right of the stack looks like a kiln house. It has a louvered roof. The higher right end section probably contains fine coal hoppers. The masonry structure standing out immediately right of the stack could, by analogy with Coltness, be a row of raw meal hoppers. Assuming that the kiln's length is that of the roof louver, then the map suggests that this is around 38 m long - which is the length of Coltness kiln 2. The "kiln house" appears to be about 20 m wide, so there is probably room for two kilns (Jackson refers to "clinker making kilns"), and such a plant might be rated at around 60,000 tonnes of clinker per year. In its final years, the plant had a 900 kW finish mill capable of making 120,000 tonnes per year of Portland and pbfc, which might use 60,000 tonnes of clinker. The structures to the left of the stack are presumably for raw material drying and grinding. This account is very conjectural, and any other documentary evidence - even tangential - will contribute greatly to the understanding of this plant. Please contact me with any relevant information.

This was taken around 1935, viewed from the south. The long open-sided building to the right of the stack looks like a kiln house. It has a louvered roof. The higher right end section probably contains fine coal hoppers. The masonry structure standing out immediately right of the stack could, by analogy with Coltness, be a row of raw meal hoppers. Assuming that the kiln's length is that of the roof louver, then the map suggests that this is around 38 m long - which is the length of Coltness kiln 2. The "kiln house" appears to be about 20 m wide, so there is probably room for two kilns (Jackson refers to "clinker making kilns"), and such a plant might be rated at around 60,000 tonnes of clinker per year. In its final years, the plant had a 900 kW finish mill capable of making 120,000 tonnes per year of Portland and pbfc, which might use 60,000 tonnes of clinker. The structures to the left of the stack are presumably for raw material drying and grinding. This account is very conjectural, and any other documentary evidence - even tangential - will contribute greatly to the understanding of this plant. Please contact me with any relevant information.

Too little is known of the plant to derive a convincing capacity history.

Picture: ©Historic England - NMR Aerofilms Collection. Britain from Above reference number SPW020311.

Picture: ©Historic England - NMR Aerofilms Collection. Britain from Above reference number SPW020311.Britain from Above features some of the oldest and most valuable images of the Aerofilms Collection, a unique and important archive of aerial photographs. You can download images, share memories, and add information. By the end of the project in 2014, 95,000 images taken between 1919 and 1953 will be available online.

This was taken on 4/2/1928 and shows the plant from the south, with the GISCO iron works in the foreground. Although even less distinct, this in HD shows what could be kilns through the openings in the cladding of the kiln house. In the top-left is the slag "bing" quarried away by the plant.

View in High Definition

GISCOL Brand. Logo used pre-1929 by the Glasgow Iron & Steel Co.

Caledonian Brand. The Caledonian Portland Cement Co. Ltd. distributed the product of Coltness, Gartsherrie and Wishaw from 1929.

Location:

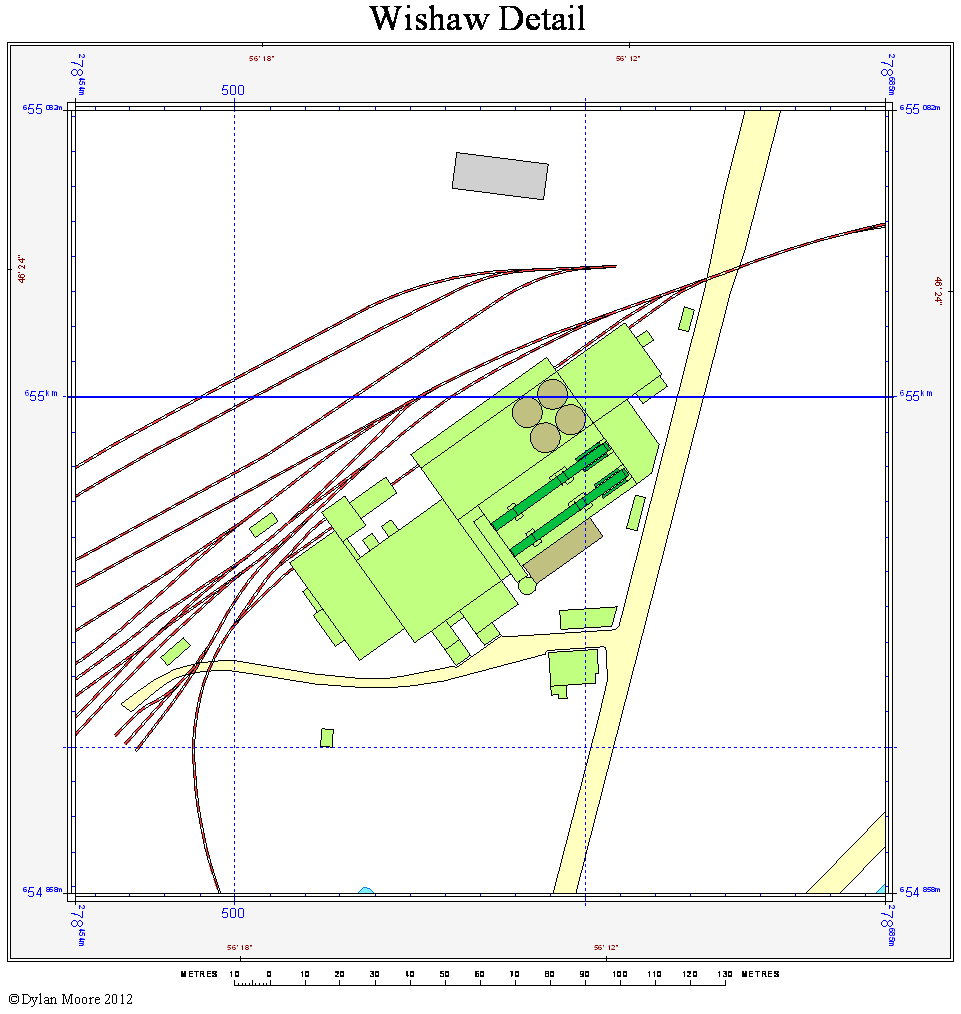

- Grid reference: NS78565498

- x=278560

- y=654980

- 55°46'22"N; 3°56'9"W

- Civil Parish: Cambusnethan, Lanarkshire - Burgh of Wishaw.

Clinker manufacture operational: ?1918-1/12/1957. GISCO began advertising Portland cement among its products in January 1916, but this may have been bought in, or Colloseus cement.

Approximate total clinker production: ?0.6-1.6 million tonnes

Raw materials:

- Blastfurnace slag from the Wishaw Iron Works until 1930, and subsequently from other plants and slag heaps around the Motherwell area

- Carboniferous Limestone (Blackhall Limestone: 326-331 Ma, and others) from the Cousland area and from Harburn, Midlothian (Burdiehouse Limestone, 326-345 Ma, at 303600,659700). The latter mine was purchased by GISCO in the 1920s.

- sand from ?

Ownership:

- 1912-1967 Glasgow Iron and Steel Co.

- 1967-1970 GI&SC / APCM joint venture.

- 1970-1974 APCM.

The plant had a history similar to Coltness, initially making Colloseus activated slag cement, and then making clinker from the slag with rotary kiln(s), to make a PBFC product. The evidence for this consists of tangential references in the local press. Evidently the kiln plant was more or less installed in 1914, when the German commissioning team were all interned due to the outbreak of the war, and final start-up was delayed until they were released four years later. The buildings shown on the map could conceivably have contained rotary kilns and the length of the kiln house suggests that these may have been similar to Coltness A2, which had satellite coolers. On the other hand, the height of the kiln house suggests a rotary cooler below the kiln, which might be similar to Coltness A1. The plant installed the first British electrostatic precipitator in 1928. The adjacent iron works shut down in 1930, but as with Coltness, granulated slag could have been brought in from other sites in later years. The 1938 and 1957 OS maps suggest that there was a very substantial slag heap ("bing") on the western part of the site, where the Wishaw General Hospital now stands, and that this was gradually quarried away during the life of the plant. The plant continued as part of the Caledonian consortium (with Coltness and Gartsherrie) to sell its cement. The plant closed for clinker production on 1/12/1957, but continued grinding cement using clinker supplied by Blue Circle. The site was acquired by Blue Circle in January 1967 and continued until 1974 making Portland and PBFC using clinker brought from various sources, including Whitehaven and Widnes.

Power Supply

Unknown, but by analogy with Coltness, the plant was probably all electric, using power generated by the iron works, and subsequently purchased power.

Rawmills

Dry process - no information.

There was at least one rotary kiln, but I have no information on it.

Please contact me with any relevant information or corrections.

Sources: