Materials used in the Cement Industry in Britain and Ireland

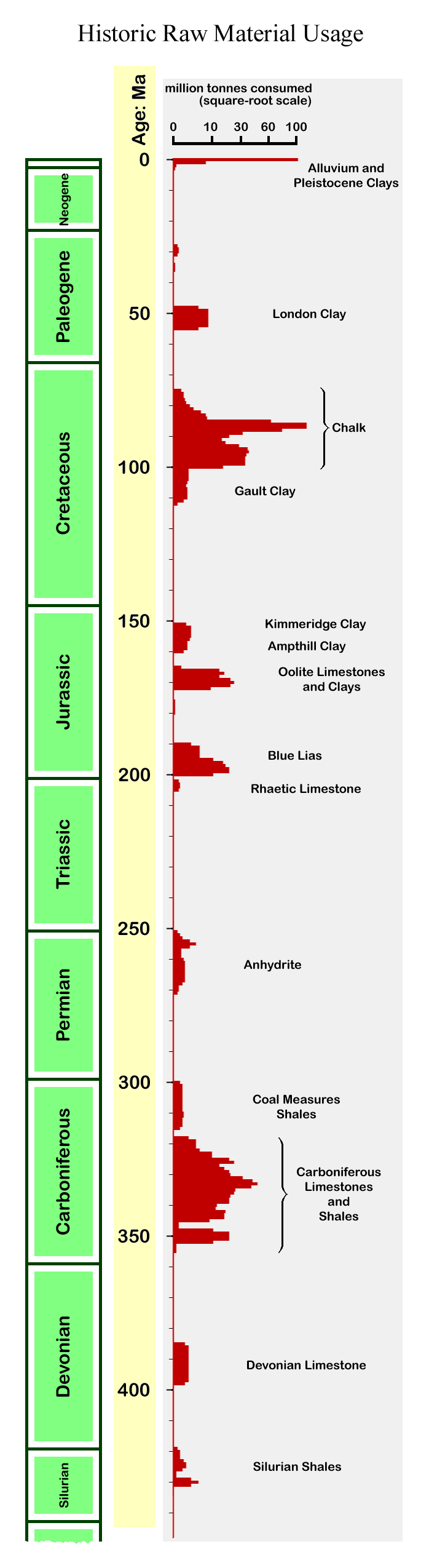

Almost any mineral can be used in a cement rawmix, provided that the bulk composition of the mixture will produce the desired calcium silicates and fluxes (see clinker), and provided that certain deleterious components are minimized. Broadly speaking, minerals containing high levels of calcium (usually the carbonate) are blended with lower-calcium minerals containing silicon, aluminium, and iron. Here follows a list of materials that have been used in cement manufacture in Britain and Ireland, arranged in order of their geological age. In addition to these, a number of industrial waste materials have been used as mix components throughout the history of the industry. The process of combining these materials into the final rawmix is discussed under Raw Material Preparation.

| Traditional name | Period | Age Ma | CaCO3 content |

|---|---|---|---|

| Alluvium | Holocene | 0-0.01 | 0-5% |

| Boulder Clay | Pleistocene | 0.01-1.6 | 5-40% |

| Hamstead Marl | Oligocene | 28-34 | 20-40% |

| Bembridge Limestone | Oligocene | 34-36 | 75-85% |

| London Clay | Eocene | 48-55 | 2-10% |

| Upper Chalk | Cretaceous | 70-90 | 92-99% |

| Middle Chalk | Cretaceous | 90-94 | 85-98% |

| Grey Chalk | Cretaceous | 94-97 | 80-92% |

| Chalk Marl | Cretaceous | 97-100 | 50-75% |

| Gault Clay | Cretaceous | 100-112 | 20-40% |

| Kimmeridge Clay | Jurassic | 151-156 | 2-10% |

| Corallian Clay | Jurassic | 156-160 | 2-10% |

| Cornbrash Limestone | Jurassic | 165 | 85-95% |

| Great Oolite Limestone | Jurassic | 166-168 | 70-90% |

| Great Oolite Clay | Jurassic | 166-168 | 5-45% |

| Inferior Oolite Limestone | Jurassic | 168-176 | 85-95% |

| Blue Lias Limestone | Jurassic | 190-200 | 70-85% |

| Blue Lias Shale/Clay | Jurassic | 190-200 | 30-50% |

| Rhaetic Limestone | Triassic | 200-205 | 85-95% |

| St Bees Shale | Permian | 252-260 | 5-15% |

| Anhydrite | Permian | 251-271 | CaSO4 |

| Coal Measures Shale | Carboniferous | 300-315 | 2-10% |

| Coal Measures Limestone | Carboniferous | 300-315 | 60-80% |

| Carboniferous Limestone | Carboniferous | 330-355 | 70-99% |

| Carboniferous Shale | Carboniferous | 318-355 | 5-15% |

| Devonian Limestone | Devonian | 385-398 | 75-95% |

| Ludlow Limestone | Silurian | 423-426 | 75-98% |

| Wenlock Limestone | Silurian | 427-428 | 75-98% |

| Upper Silurian Shales | Silurian | 419-430 | 1-5% |

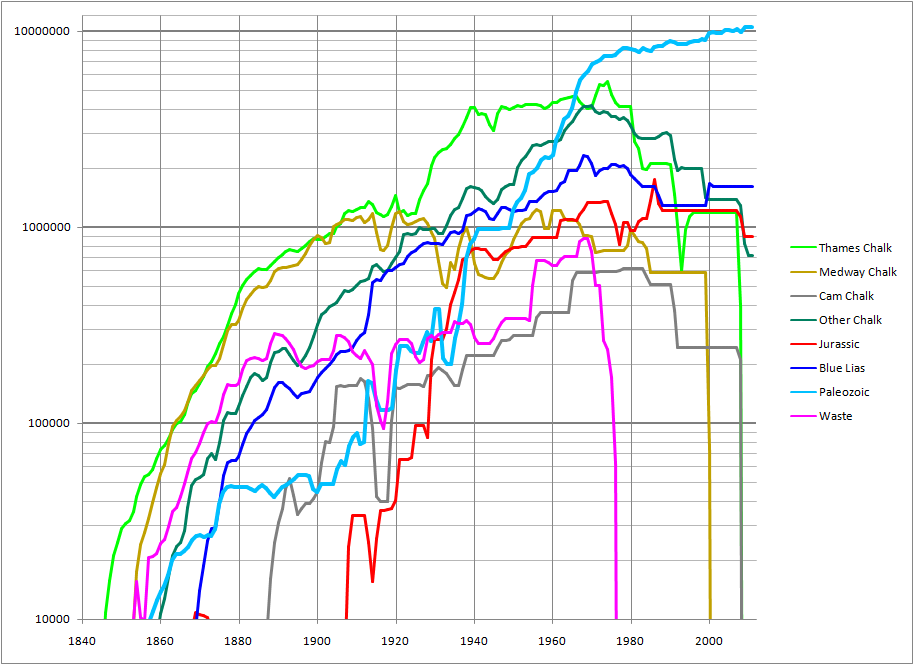

Variation of Industry Capacity (annual clinker tonnes) by Raw Material Type