Preparation of a detail plan remains impossible due to an almost complete lack of layout information and site plans.

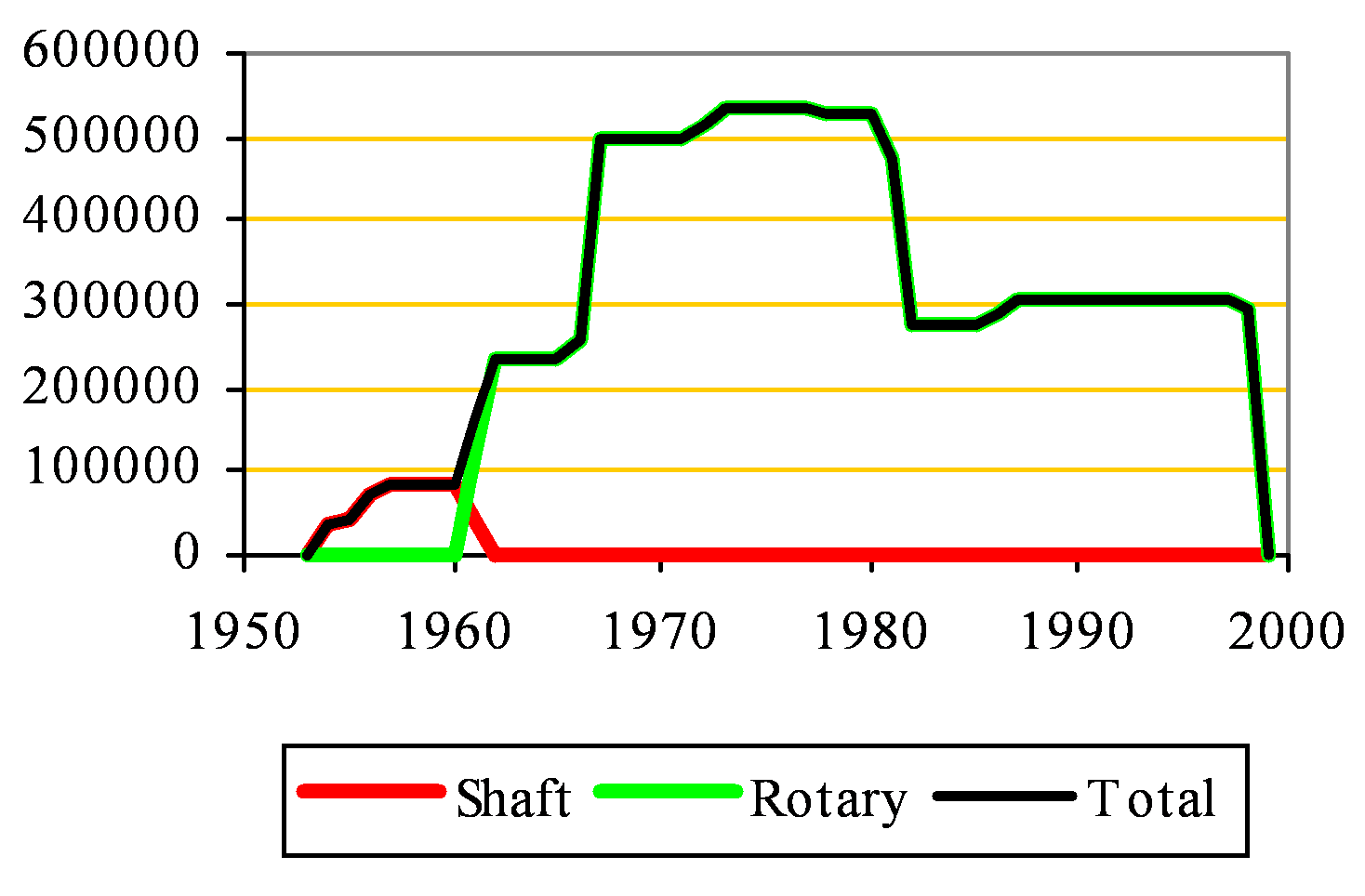

Approximate capacity: tonnes per year

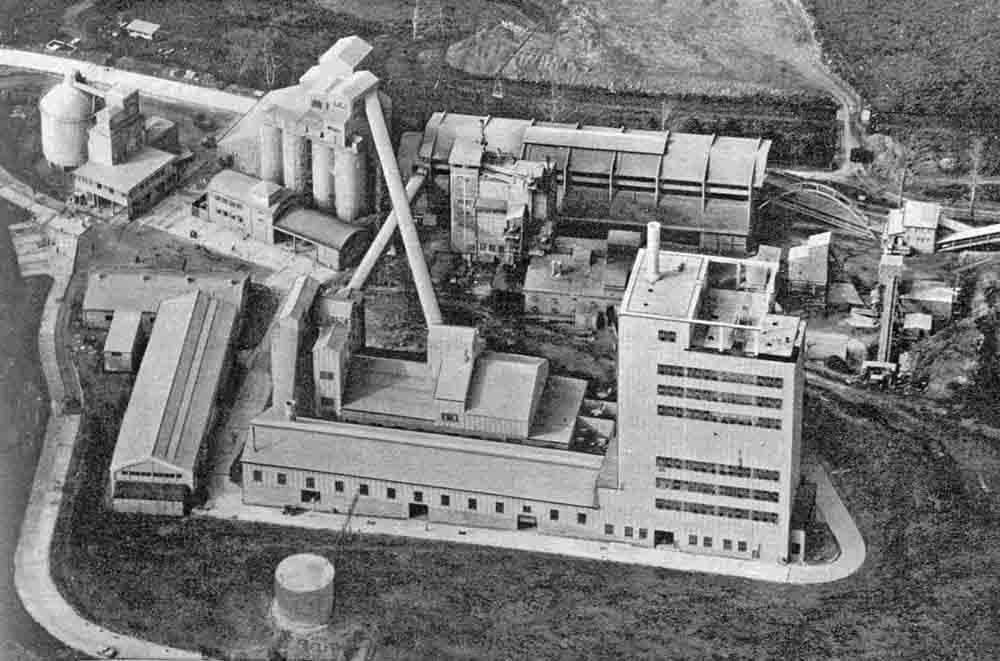

Picture: Blue Circle Archive. This was taken in 1961, viewed from the south. This shows the first rotary kiln building in the foreground, with the finish mill building immediately behind. The old shaft kilns are beyond, immediately in front of the limestone/clinker store constructed in 1960. The limestone drying/grinding plant for the shaft kilns is to the right of the kilns. The conveyors and crushers on the right edge were associated with the lime plant that originally occupied the site.

Picture: Blue Circle Archive. This was taken in 1961, viewed from the south. This shows the first rotary kiln building in the foreground, with the finish mill building immediately behind. The old shaft kilns are beyond, immediately in front of the limestone/clinker store constructed in 1960. The limestone drying/grinding plant for the shaft kilns is to the right of the kilns. The conveyors and crushers on the right edge were associated with the lime plant that originally occupied the site.

Picture: ©Historic England - NMR Aerofilms Collection. Catalogue number A198907. A high-definition version can be obtained from Historic England. This was taken on 4/9/1969, showing the two-kiln plant, viewed from the northwest. The River Plym is in the foreground. The old shaft kilns were located in the empty area below and left of the rawmix silos. The crushers are in the mouth of the quarry at the top left. Stone is conveyed to the A-frame stone store, then to the rawmills behind the preheater tower. The kilns were oil-fired, and the oil tanks are in the top-right. Clinker silos and finish mills are located to the left of the kilns.

Picture: ©Historic England - NMR Aerofilms Collection. Catalogue number A198907. A high-definition version can be obtained from Historic England. This was taken on 4/9/1969, showing the two-kiln plant, viewed from the northwest. The River Plym is in the foreground. The old shaft kilns were located in the empty area below and left of the rawmix silos. The crushers are in the mouth of the quarry at the top left. Stone is conveyed to the A-frame stone store, then to the rawmills behind the preheater tower. The kilns were oil-fired, and the oil tanks are in the top-right. Clinker silos and finish mills are located to the left of the kilns.

Picture: ©NERC: British Geological Survey Cat. No. P539358. This is Kiln 1, taken in 1961, viewed from the base of the preheater. The casing of the kiln drive is in the foreground.

Picture: ©NERC: British Geological Survey Cat. No. P539358. This is Kiln 1, taken in 1961, viewed from the base of the preheater. The casing of the kiln drive is in the foreground.

Location:

- Grid reference: SX50684260

- x=250685

- y=054260

- 50°22'9"N; 4°5'58"W

- Civil Parish: Plymstock, Devon

Clinker manufacture operational: 2/1954 - 31/05/1999

Approximate total clinker production: 12.3 million tonnes (35th).

Raw material: Devonian Limestone (Middle Devonian Limestone: 385-398 Ma) from the Saltram Quarry at 251400,054300

Ownership:

- 2/1954-31/5/1958 Amalgamated Limestone Corporation

- 1/6/1958-1999 APCM (Blue Circle)

Called Saltram Works by its first owners. This was the most southerly cement plant, and the most westerly in Great Britain: as a far-flung part of the country, the cost of cement delivery from the Thames was high, and a cement plant here was planned as early as the late 1930s by the owners of the limestone quarries at Plymstock. Interrupted by the war, the plant finally commenced operations on a small scale with a shaft kiln using the "black meal process": a second one was added three years later. Technical management was supplied by Cementia. These kilns were operated independently, but their inputs and outputs were combined. The kiln feed was dry-ground and blended, then nodulized in a pan nodulizer with the addition of 12.6% water. On acquisition by Blue Circle, the shaft kilns were replaced by rotary kiln A1. This was the first British suspension preheater kiln, and the third efficient kiln to be installed, preceded only by Cauldon A1 and A2 Lepol kilns. The experience with the shaft kilns was sufficient to show that the material did not nodulize well, so the “Humboldt” preheater, which had the majority of the market at the time, was selected in preference to the Lepol grate.

Please contact me with any relevant information or corrections. I am particularly interested in firmer dates and statistics.

Power supply

The plant was entirely electrically powered from the grid from the outset.

Rawmills

- In the shaft kiln plant, a Berz and two REMA ring-roller mills were used – size unknown. Heat was supplied by a small oil-fired furnace.

- Each rotary kiln had a 1230 kW Humboldt air-swept ball mill with tandem hammer mill, with heat supplied by kiln exhaust gases.

Shaft Kilns

Supplier: ?Loesche

Operated: #1 2/1954-1961: #2 1956 (1st half)-1961

Process: Semi-dry: shaft kiln

Location: kiln 1 at 250669,54344; kiln 2 at 250646,54348.

Dimensions: Metric

- Height 8.50

- Upper ID 3.000

- Burning zone ID 2.400

- Cooling zone ID 2.500

Cooler: Integral

Fuel: Coke

Typical Output (each): 115 t/d

Typical Heat Consumption: 4.87 MJ/kg

Two rotary kilns were installed.

Kiln A1

Supplier: kiln - Vickers Armstrong: preheater - KHD.

Operated: 9/1961-19/10/1981

Process: Dry SP4 suspension preheater

Location: hot end 250657,054261: cold end 250710,054272: entirely enclosed

Dimensions: 178’0”× 12’6” (metric 54.25×3.810)

Rotation (viewed from firing end): anticlockwise

Slope: 1/33.33 (1.719°)

Speed: 1.4 rpm

Drive: 67 kW

Kiln profile: 0×3810: 53861×3810: 53861×3251: 54254×3251: tyres at 3658, 24994, 47854: turning gear 45415.

Cooler: Fuller 741H grate

Fuel: 1961-1979 Oil: 1979-1981 Coal

Coal mill: ?

Exhaust: preheater gases via the rawmill to two parallel electrostatic precipitators then through the precipitator ID fan to the stack.

Typical Output: 1961-1972 702 t/d: 1972-1981 748 t/d

Typical Heat Consumption: 1961-1977 3.80 MJ/kg: 1977-1981 4.13 MJ/kg

Kiln A2

Operated: 04/12/1966-31/05/1999

Process: Dry SP4 suspension preheater: fitted with afterburner 1990

Location: hot end 250660,054246: cold end 250713,054257: entirely enclosed

Cooler: Claudius Peters 744H grate

Fuel: 1966-1978 oil: 1978-1998 coal, from 1983 up to 20% replaced with petcoke.

Coal mill: direct: Babcock & Wilcox 5E ball-race mill (1575 mm)

Typical Output: 1966-1972 781 t/d: 1972-1978 864 t/d: 1978-1986 831 t/d: 1986-1998 913 t/d

Typical Heat Consumption: 1966-1978 3.76 MJ/kg: 1978-1998 4.06 MJ/kg

In all other respects identical to A1

Sources:

- Primary Sources:

- Greenhithe Archive

- ALC company reports

- "Developments at a Cement Works in Britain", Cement and Lime Manufacture, 33, July 1960, pp 49-53

- "A New Rotary Dry-process Kiln in Gt. Britain", Cement and Lime Manufacture, 35, Jan 1962, pp 1-8, 23-28

- Ordnance Survey 1:2500 mapping

- BGS mapping and monographs

- Confirmatory Sources: