The following is a transcript of two anonymous articles that appeared in The Engineer, 56, 19/10/1883, p 303; 56, 30/11/1883, p 421 and 62, 8/10/1886, pp 291-2. They are believed to be out of copyright. The 1886 article describes the original plant at Arlesey, which is an example of the "off-the-peg" chamber kiln plant in its simplest form. It also gives a useful close-up on a typical finish mill installation of the time. Note on Imperial units of the time: 1 ton = 1.016047 tonnes: 1 ft = 0.304799 m: 1 in = 25.4 mm: 1 h.p. = 0.7457 kW: 145.037 psi = 1 MPa.

NEW PORTLAND CEMENT WORKS AT ARLESEY.

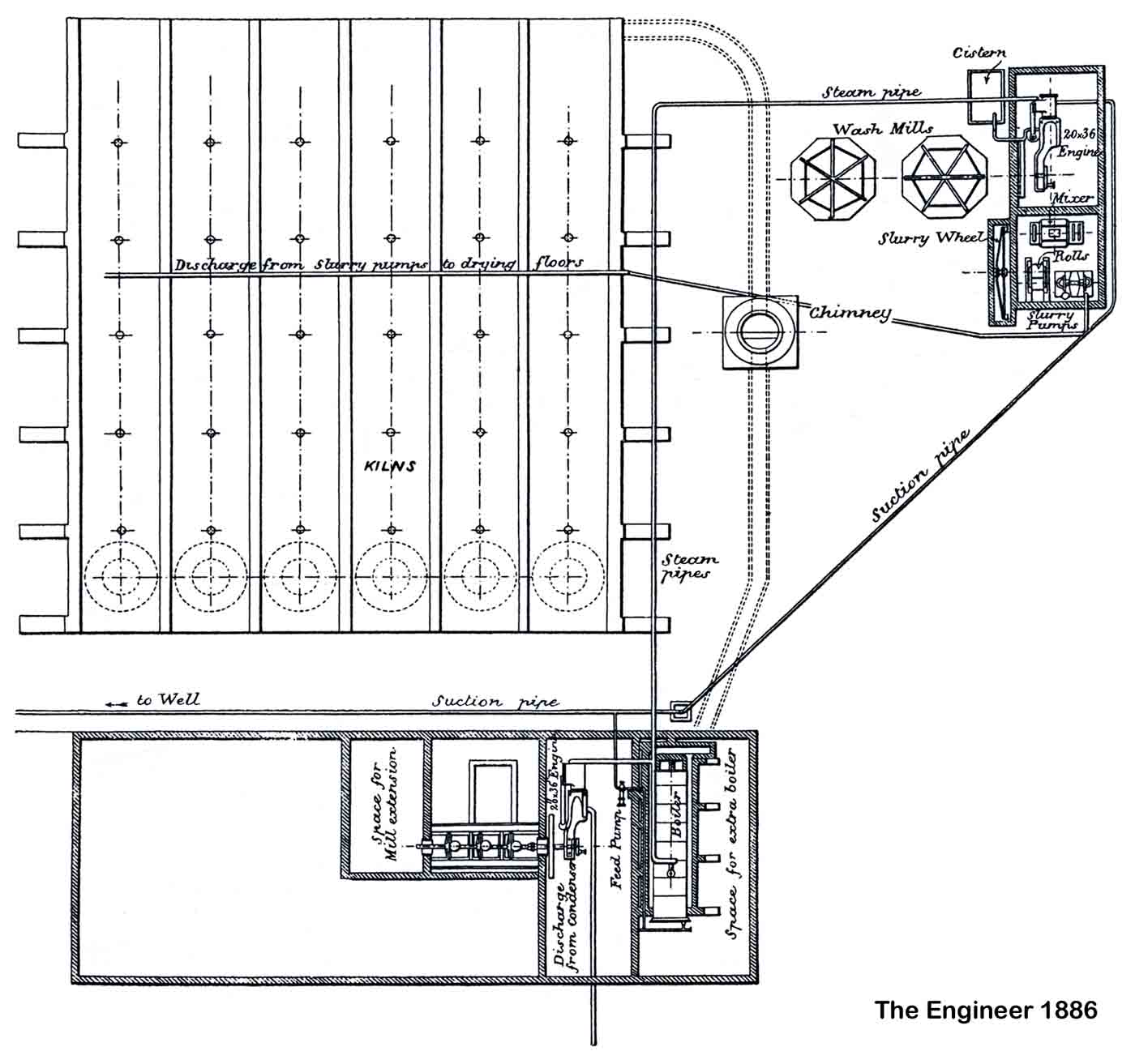

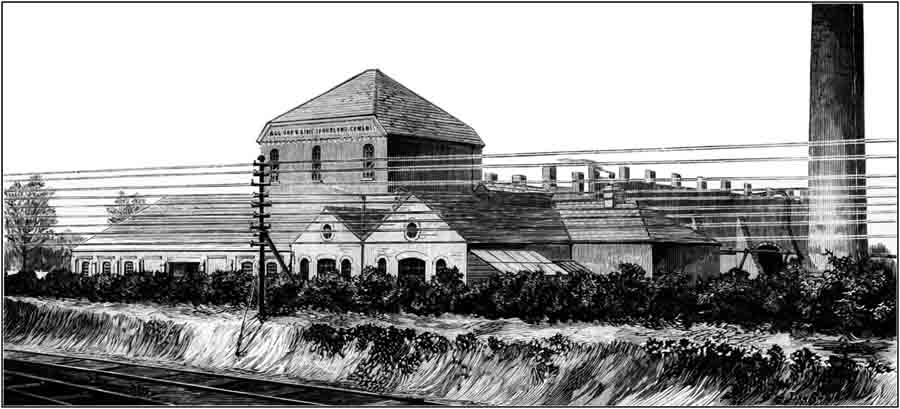

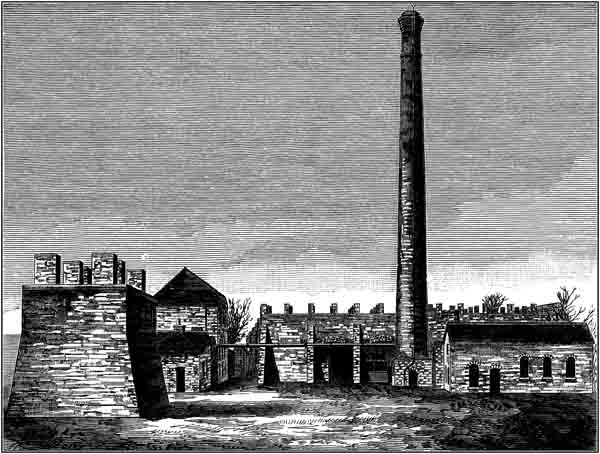

The illustrations show the side nearest to the Great Northern Railway of the Portland Cement Works recently erected at Arlesey Siding, Great Northern Railway, by the Arlesey Lime and Portland Cement Company, and the smaller engraving shows the opposite side (Note 1). A plan of the works is given (below). The whole of the building, machinery, &c., were designed by the Pulsometer Engineering Company (Note 2), which has also manufactured and supplied the machinery. The works are now turning out Portland cement of the highest quality. The machinery already erected consists of two similar horizontal condensing engines 20 in. diameter of cylinder by 36 in. stroke, running at 60 revolutions per minute, fitted with variable expansion gear, and each capable of indicating from 93 to 180 horse-power.

One of these is used for driving:

- the slurry mills, each 18ft. diameter;

- the slurry wheel 18 ft. diameter, for raising the slurry, which is driven at slow speed by new differential gear;

- a set of special rolls through which all the cement slurry is passed;

- the mixer, a new machine for incorporating the slurry;

- slurry plunger pumps, 10in. diameter by 16in. stroke, which raise the slurry, after it has passed through mills, rolls, and mixer, to the top of the kilns.

The second engine actuates:

- a specially designed crusher which reduces the cement clinkers to pieces about ⅜ in. cube, so as to diminish the work performed by the stones;

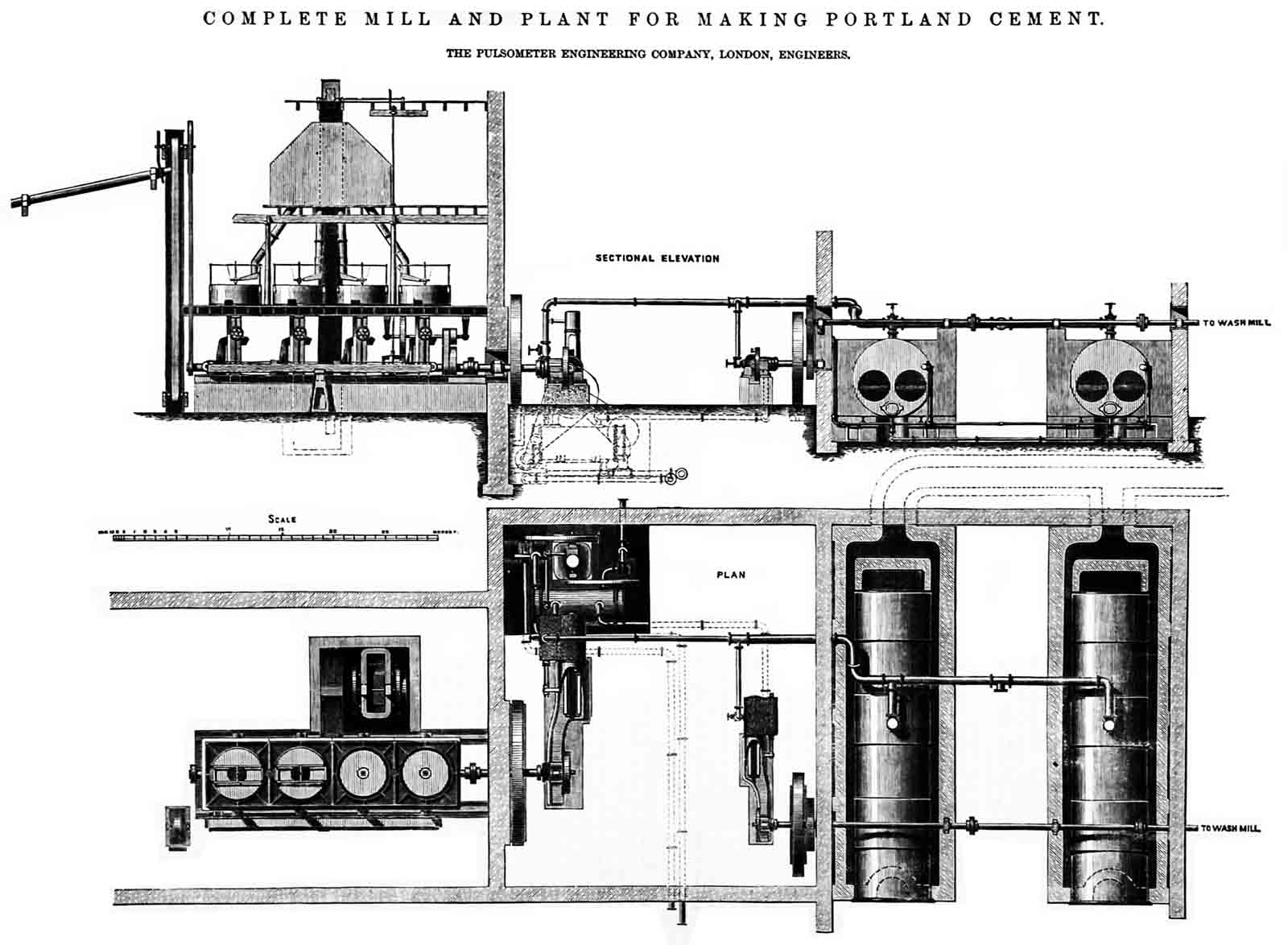

- the mills, which are of the Pulsometer Engineering Company's self-contained pattern already illustrated in "The Engineer" (see below).

A single Lancashire boiler 7 ft. by 28ft—steel—working at a pressure of 80 lb., furnishes steam for the whole installation. It is fed by a Deane steam pump 5½ in. by 3¾ in. by 10in. stroke. Special interest attaches to these works, costly and fruitless attempts (Note 3) having been made in times past to manufacture Portland Cement from materials on the estate. This is, we believe, the only locality near London in which gault clay and chalk are found together (Note 4). Careful analyses made by Mr. G. M. R. Layton (Note 5), the managing director, proved that these materials were capable of being manufactured into cement of high quality, and the sub-joined tests will show that with care and judgment no materials can be more beneficially employed for the purpose. Average breaking strain after seven days of 100 briquettes of 1½ in. by 1½ in. by Adie's machine, 1020.42 lb. Average of 50 1 in. briquettes, 398 lb (Note 6). The cement is already in far greater demand than can be supplied by the present kiln power, and additional kilns, patented by Mr. Layton (Note 7), are now being erected. The result of the substitution of the special rolls and mixer for the ordinary wet stones has been highly satisfactory (Note 8). The arrangements are specially made with a view to saving labour, and the progress of the material in the cheapest way direct through the works.