Blue Circle was by far the largest UK cement company thoughout the twentieth century, and its size allowed considerable investment in research. Outside Blue Circle, research investment was slight and patchy. The rapidly-expanding Rugby company set up a small central research and services facility in Rugby as late as 1971. The group of companies which became Castle relied in its early days on the research facilities of FLS. The plants associated with ICI obtained considerable support from their massive research facilities, at least in terms of chemistry. The many other small and single-plant companies had to rely on the support of their plant suppliers. However, at the start of the 20th century, all companies were in this situation.

Peter Jackson made the point that the need for research facilities became salient with the establishment of BPCM in 1912. The incipient Blue Circle now had a wide variety of plants, many provided with rotary kilns and ball mills in an ad hoc manner from multiple suppliers. There was an opportunity to apply a "best practice" approach to this motley collection - and certainly there was huge scope for a dramatic improvement in efficiency. The Joint APCM/BPCM Research Committee was set up in 1913. The work of the committee concentrated on kiln and mill optimisation. A program of in-depth snap-shot surveys of individual plant items was initiated which produced a large body of data that continued in use for many subsequent decades.

During the First World War, Government concern arose about the technical superiority of many aspects of German industry, and it was decided to encourage British industry sectors to set up shared R&D facilities on a "matched funding" basis. This scheme was launched in 1918, and the British Portland Cement Research Association (Note 1) was among the first to form, in November of that year. A paper in Nature (Note 2) by S. G. S. Panisset describes its formation. He says:

The aim of the association may be briefly summarised as an attempt to cheapen the production and to improve the quality of cement, and the achievement of this aim cannot fail to benefit the consumer while tending to stabilise the British industry. The hearty co-operation of British manufacturers in this enterprise is shown by the fact that more than 90% of their number are members of the association.

The Association took over the facilities and material of the A/BPCM Joint Research Committee wholesale, and, run almost exclusively by A/BPCM personnel, continued its activities fairly seamlessly. However, Blue Circle recognised from the outset that its internal needs extended beyond the BPCRA's remit, and used the Association's resources to establish Product and Engineering R&D departments in 1921 at Rosherville Court in Gravesend, while a central chemical laboratory was set up in a warehouse at Hollick's Wharf. The Government grant to BPCRA ceased in 1923, and in the increasingly difficult financial and political situation, no further industry finance was forthcoming, so the association was wound up in 1925, with a precis of its results to date hurriedly written up and published. The bulk of its raw data was buried in the National Archives or lost. The research facilities were acquired by A/BPCM at cost.

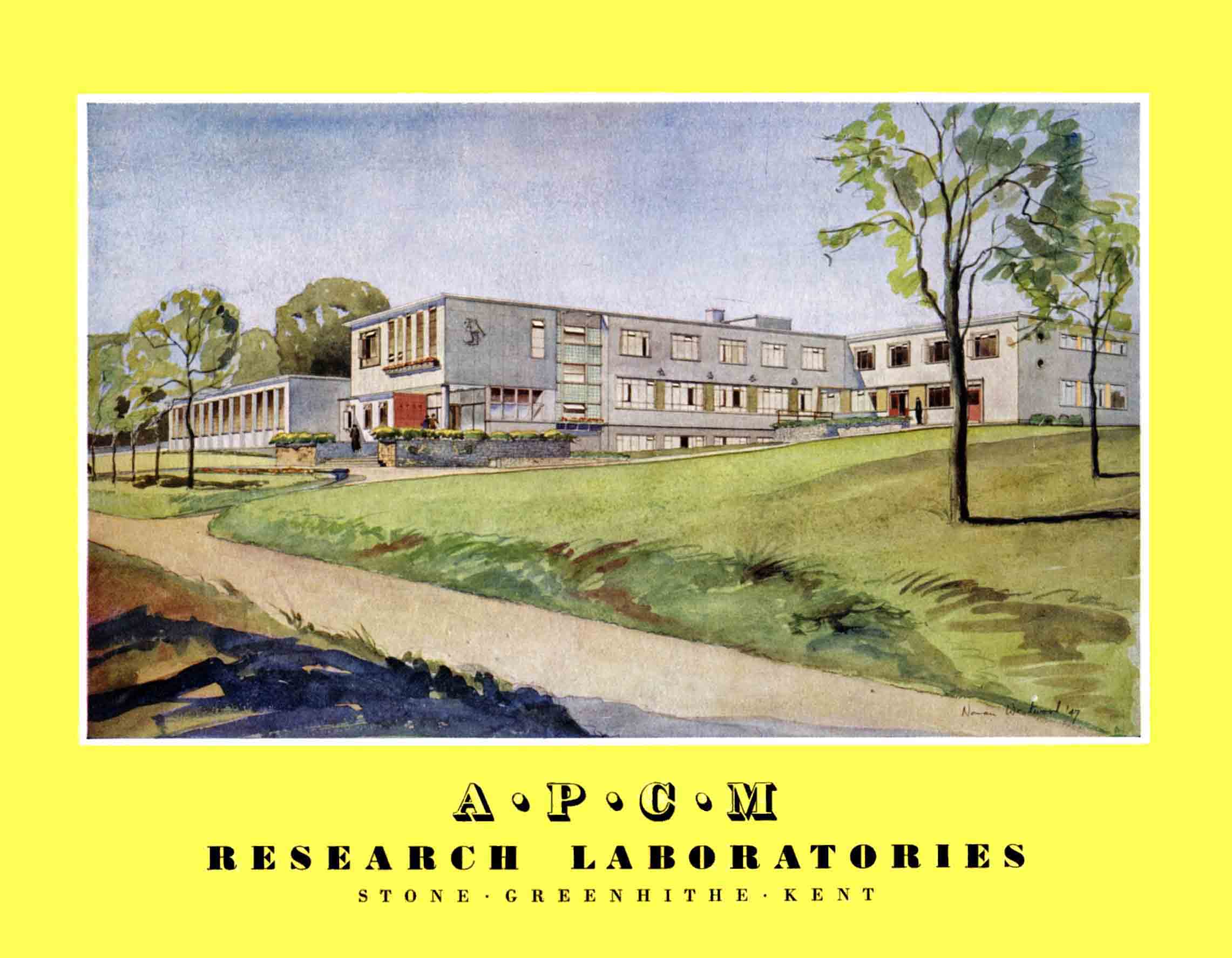

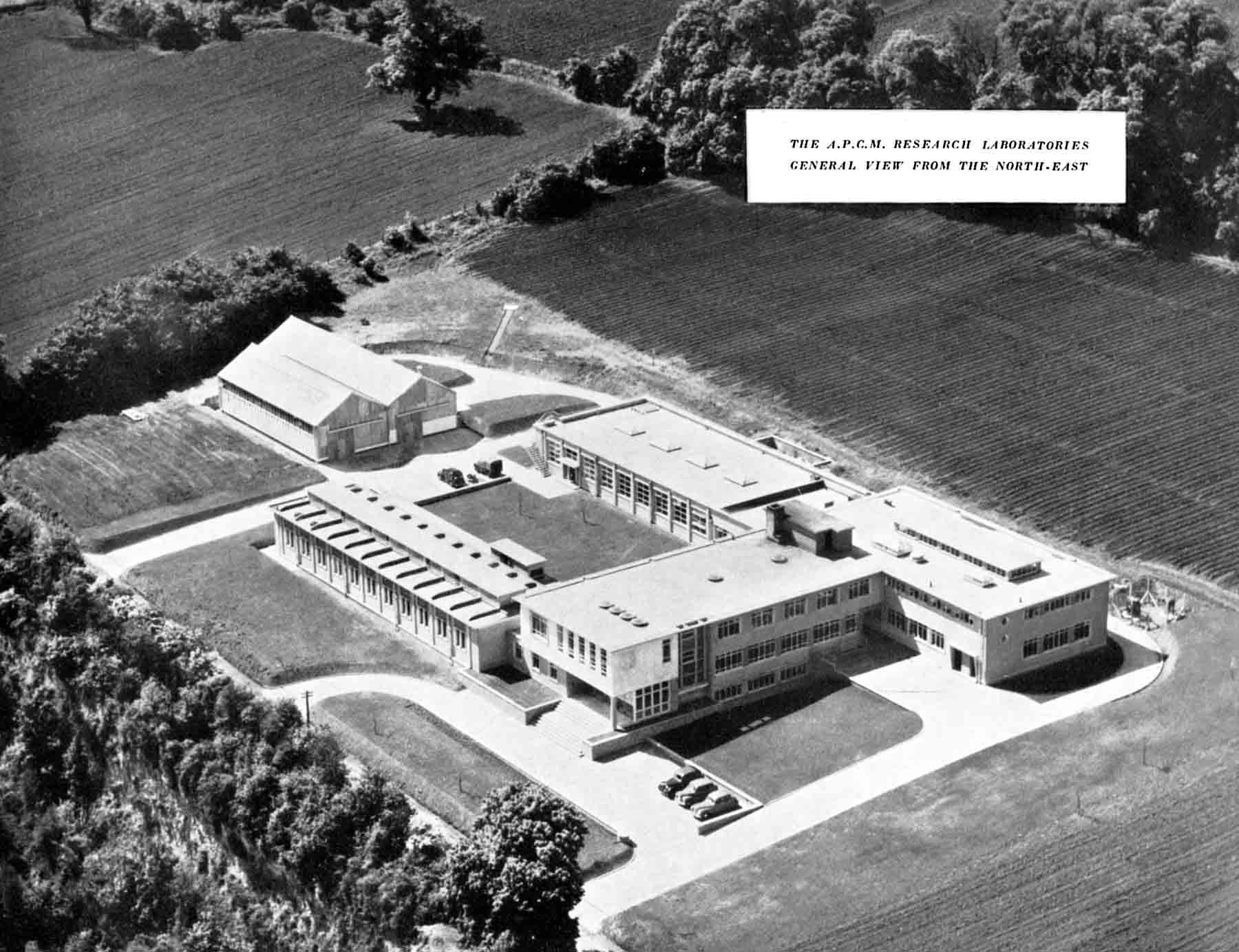

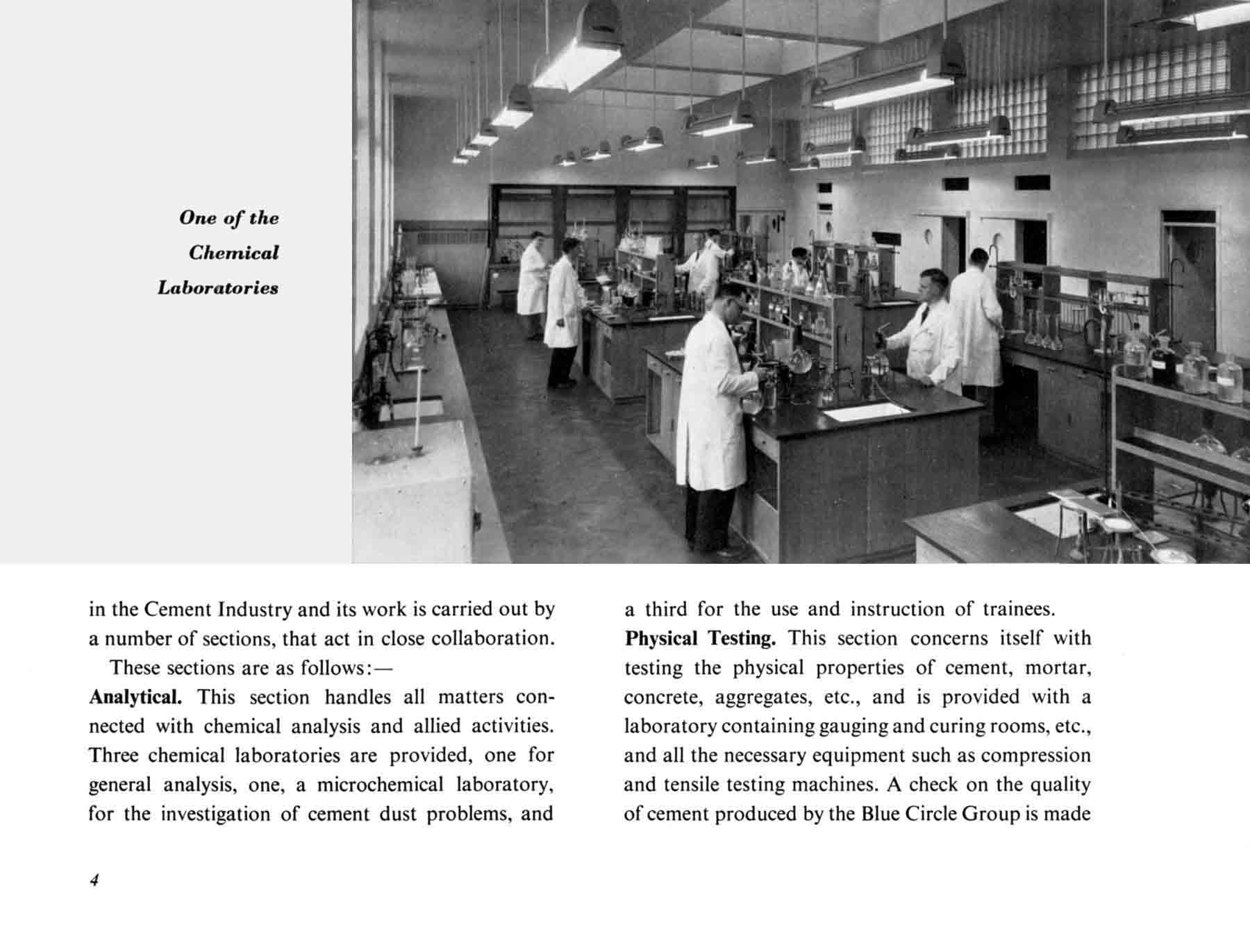

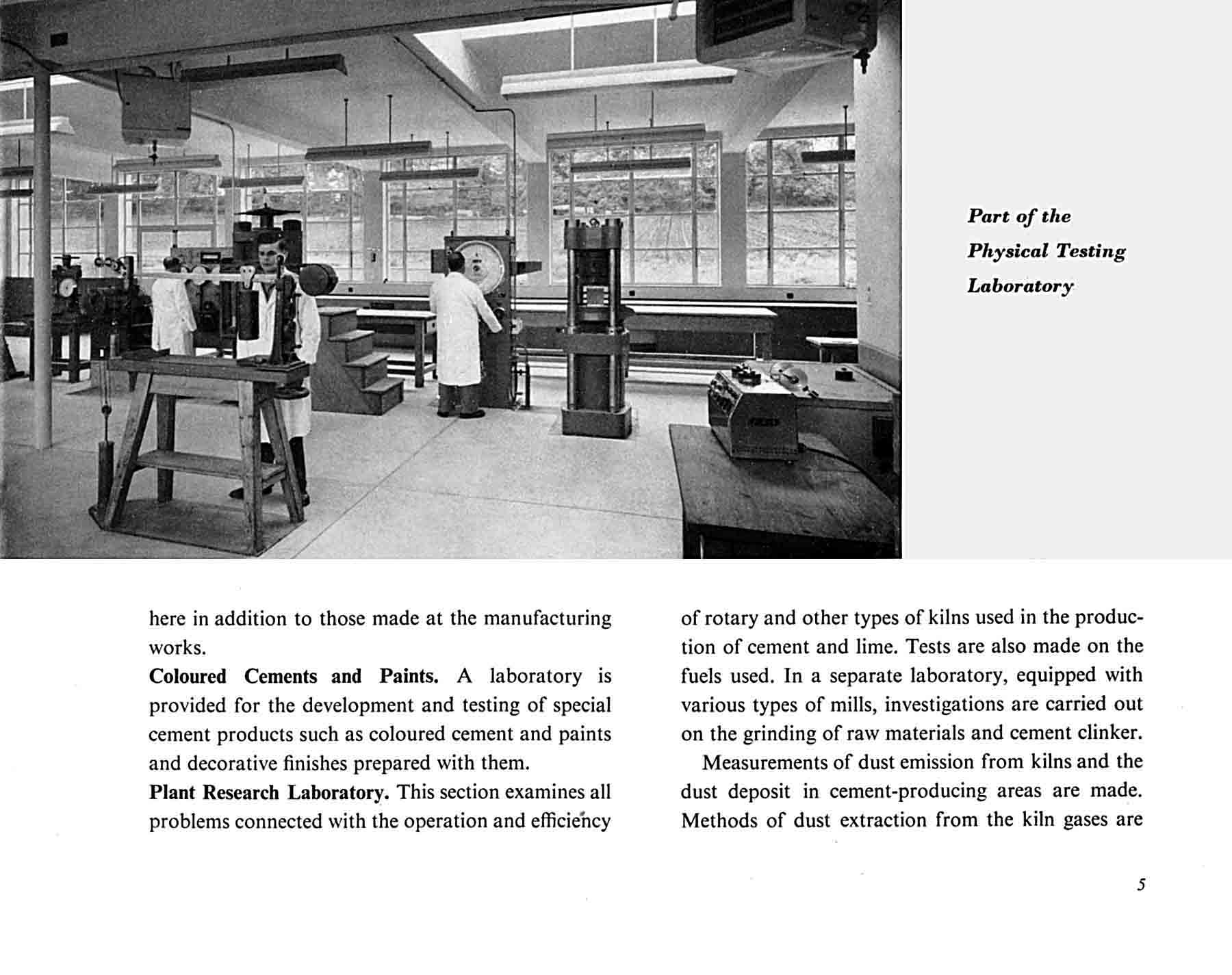

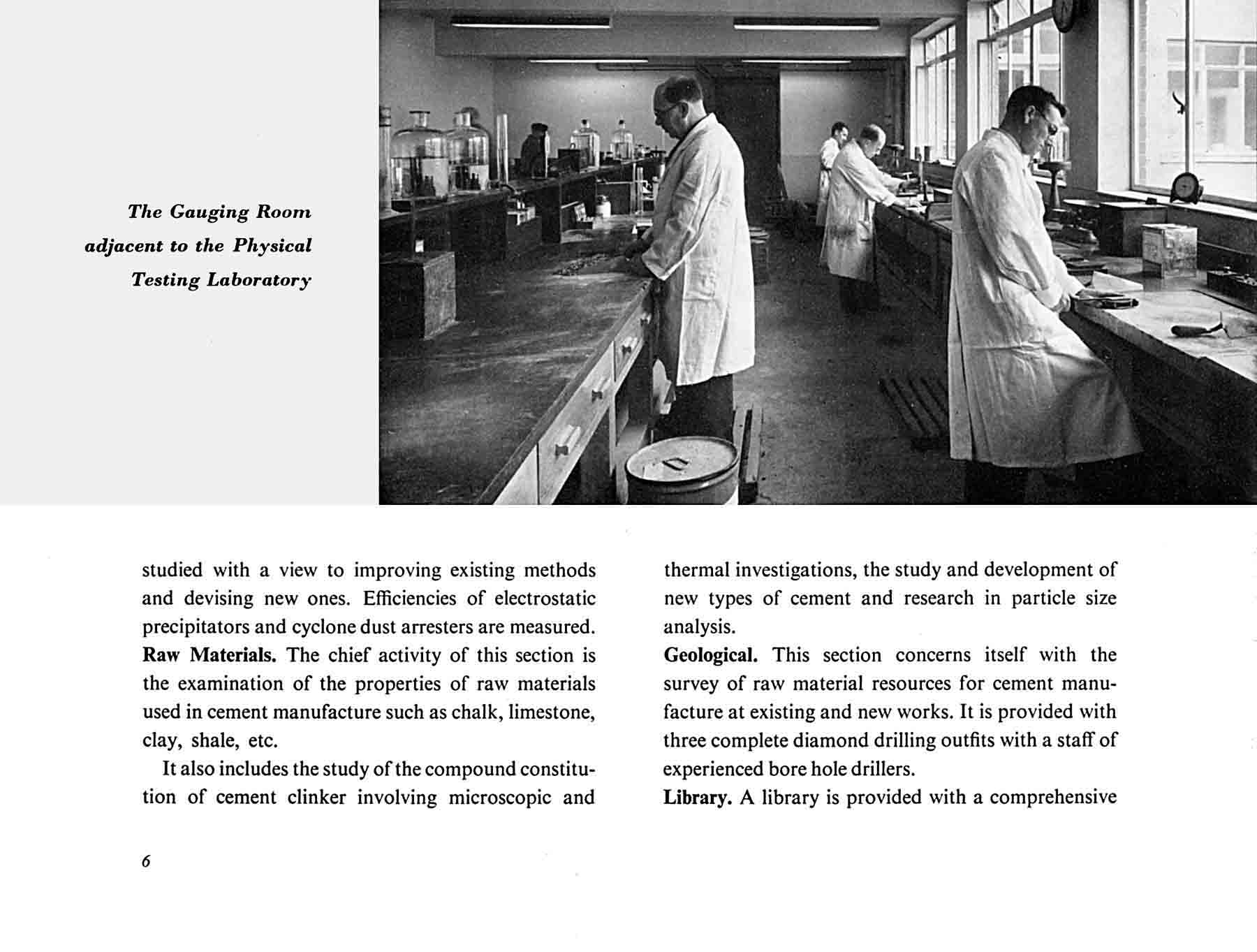

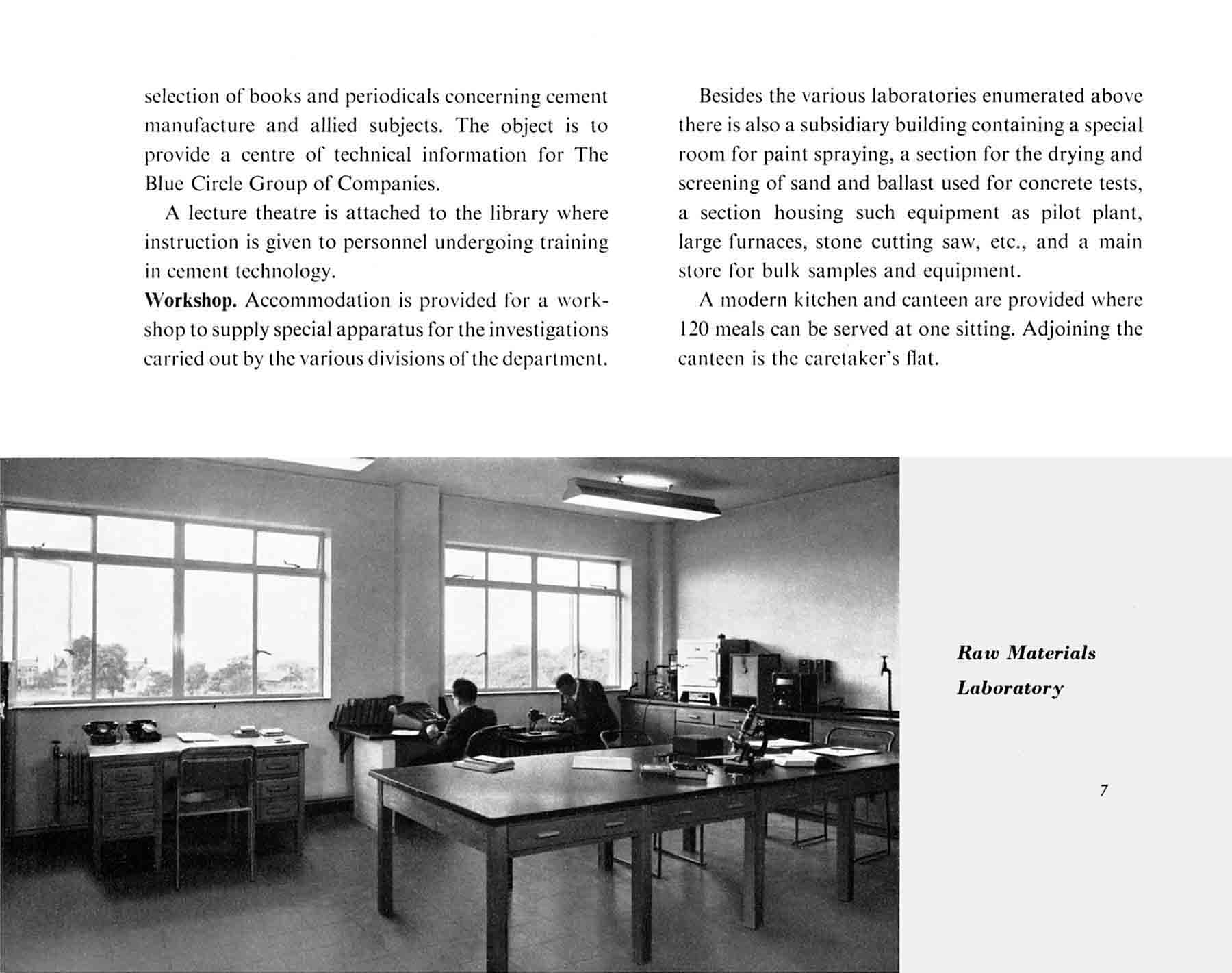

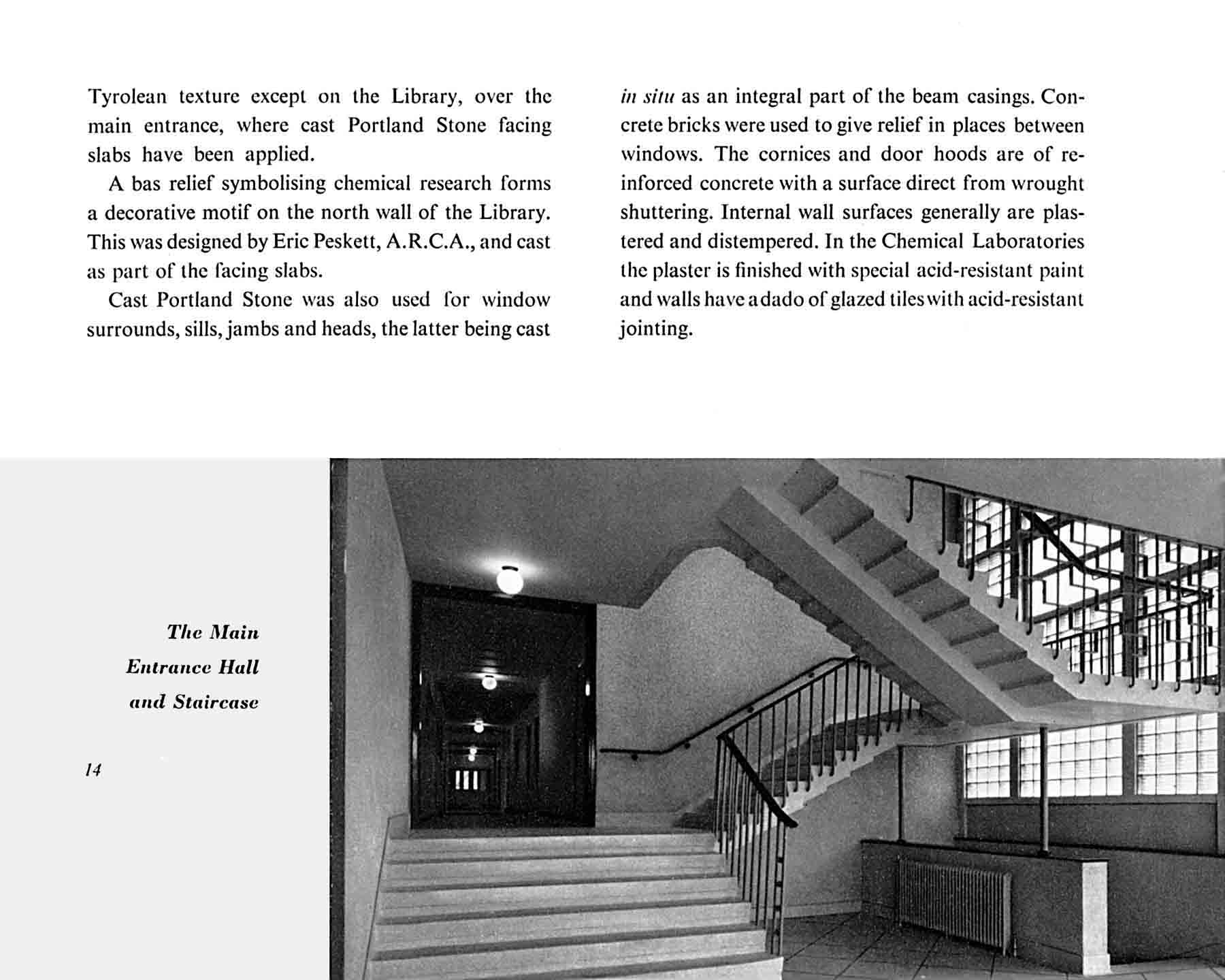

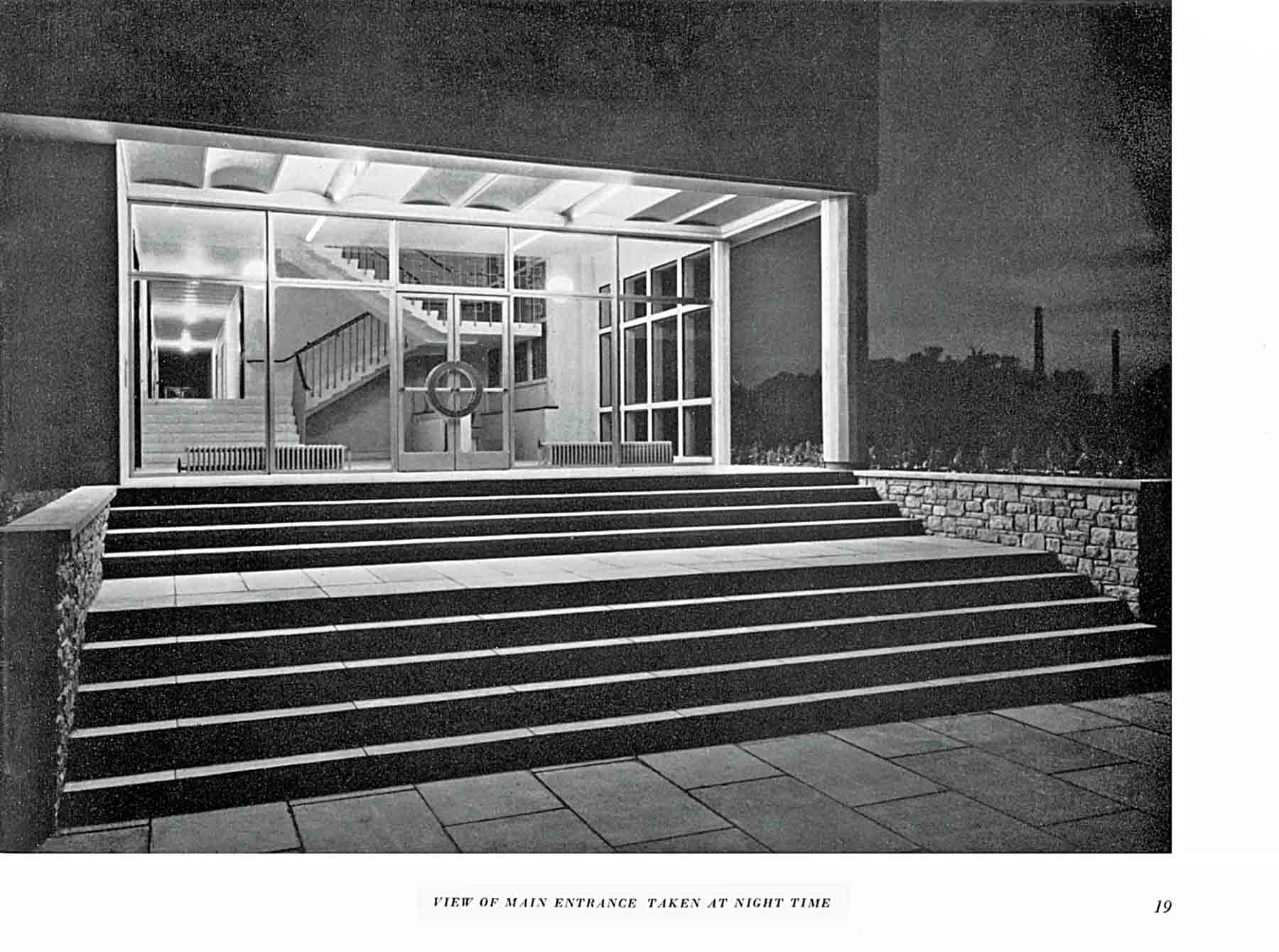

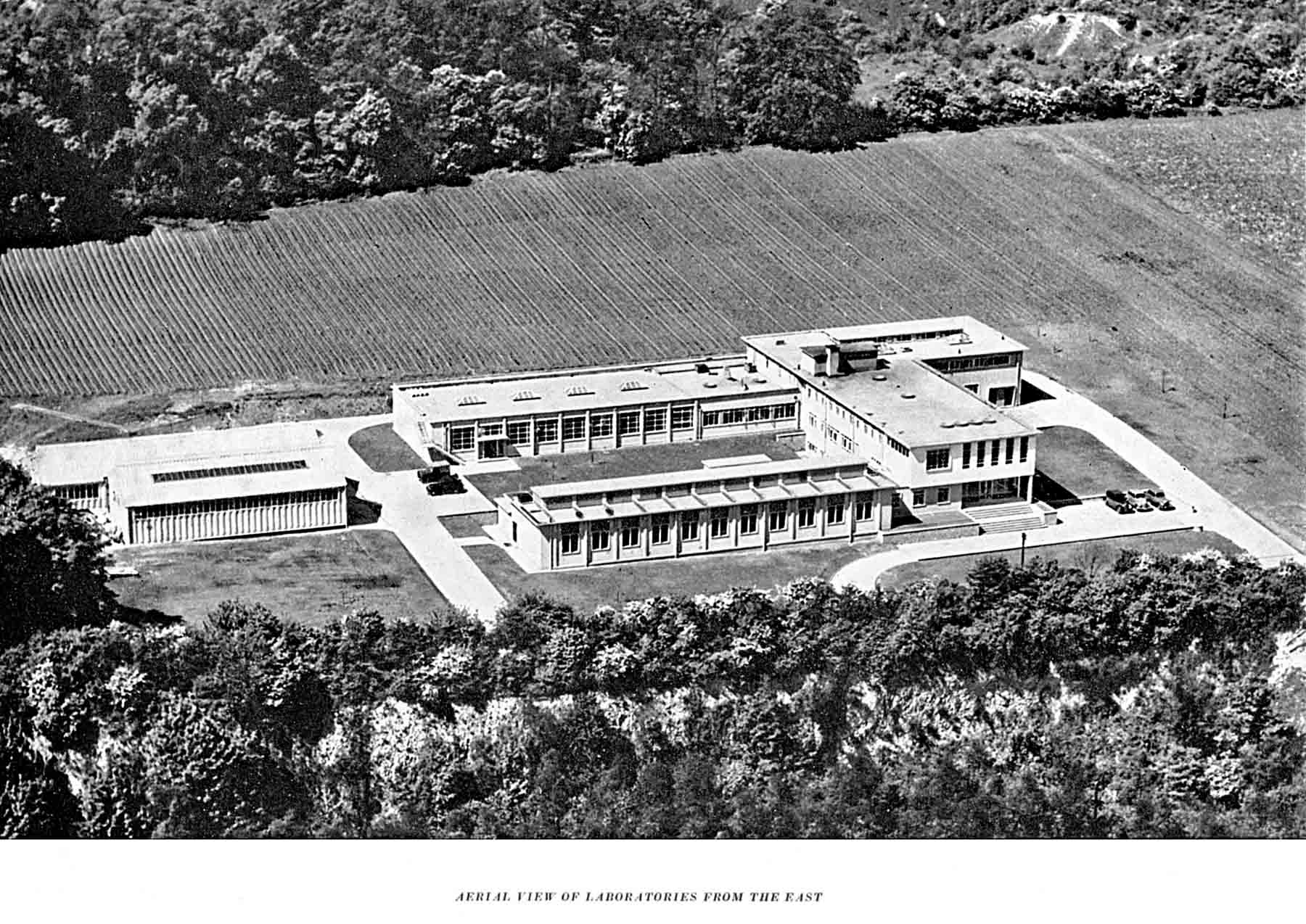

Blue Circle's R&D work continued to focus on consolidating knowledge of optimised manufacturing techniques, and on the development of special products such as rapid-hardening and white cements. After the hiatus of activity during WWII, the need for improved facilities became clear, and a new laboratory complex was built on the lands of Stone Castle, Greenhithe, long owned by Blue Circle. It was first occupied in early 1952, and was officially opened on 11 July 1952 by David Eccles, Minister of Works and Tory MP for Chippenham.

I recently (2022) got hold of a pamphlet produced for the opening of the Greenhithe buildings, now out of copyright, and here it is.