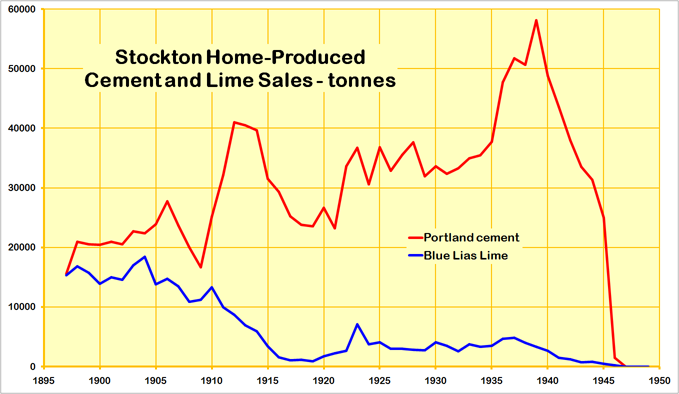

The Warwickshire County Record Office holds sales ledgers from Charles Nelson & Co's plant at Stockton (temporary catalogue numbers RS 9/5/1-5). I present the data here because it represents an exceptionally long (over 50 years) time series of uniformly-gathered data, and because it refers to the idiosyncratic history of the Warwickshire industry. In Warwickshire, the Blue Lias district produced "engineering-grade" hydraulic limes from the 18th century, and these became popular throughout Britain when the building of canals allowed them to be distributed nationwide. When Portland cement began to be produced from the 1840s onwards, Blue Lias Lime was one of the established products with which it had to compete, and the reliability of this lime ensured that it remained in favour for certain applications well into the 20th century. Its production continued at the Warwickshire plants until WWII.

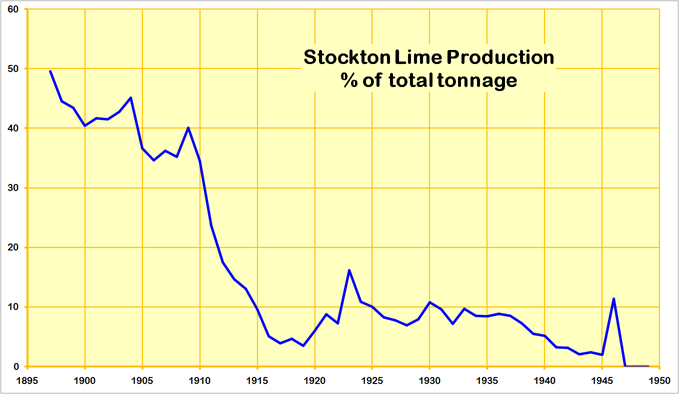

The Stockton plant was established on a site previously worked for lime in 1844. Portland cement made with a ground rawmix commenced production in 1872, and by 1886 its capacity was 15000 t/year of Portland cement and 25500 t/year of lime - about 63% lime. The lime was marketed in three forms: lump lime, ground lime and Selenitic lime. The vast majority (80-90%) was sold as ground lime, which is the familiar Blue Lias hydraulic lime, made by grinding the lump product without any slaking. Lump lime was probably made from stone from known high-carbonate floors. Selenitic lime was made by adding 5% gypsum at the grinding stage as a retarder, and was used in mortars. By the start of the following records in 1897, the relative position of lime and cement had reversed, with lime down to around 40% of tonnage.

| Year | Own Product Sold tonnes | Purchased Materials Resold tonnes | Total Sales tonnes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lump Lime | Ground Lime | Selenitic Lime | OPC | RHPC | Lump Lime | Ground Lime | Plaster | Cement | Lump Lime | Ground Lime | Selenitic Lime | Plaster | Cement | |||

| 1897 | 474 | 14042 | 800 | 15574 | 0 | 2066 | 4484 | 347 | 7304 | 2540 | 18526 | 800 | 347 | 22878 | ||

| 1898 | 953 | 14807 | 1062 | 20952 | 0 | 2526 | 4818 | 512 | 4476 | 3479 | 19625 | 1062 | 512 | 25428 | ||

| 1899 | 911 | 13712 | 1118 | 20507 | 0 | 1978 | 4098 | 500 | 5120 | 2889 | 17810 | 1118 | 500 | 25627 | ||

| 1900 | 465 | 11953 | 1471 | 20480 | 0 | 1893 | 5705 | 557 | 8152 | 2358 | 17658 | 1471 | 557 | 28632 | ||

| 1901 | 802 | 13005 | 1182 | 20955 | 0 | 1103 | 4955 | 682 | 6883 | 1905 | 17960 | 1182 | 682 | 27838 | ||

| 1902 | 878 | 12138 | 1588 | 20533 | 0 | 794 | 2863 | 563 | 6455 | 1672 | 15001 | 1588 | 563 | 26988 | ||

| 1903 | 1706 | 14241 | 1034 | 22717 | 0 | 684 | 2857 | 436 | 7686 | 2390 | 17098 | 1034 | 436 | 30403 | ||

| 1904 | 1711 | 15582 | 1106 | 22397 | 0 | 357 | 2457 | 368 | 6755 | 2068 | 18039 | 1106 | 368 | 29152 | ||

| 1905 | 3198 | 9661 | 943 | 23880 | 0 | 271 | 950 | 395 | 4712 | 3469 | 10611 | 943 | 395 | 28592 | ||

| 1906 | 2314 | 11566 | 832 | 27741 | 0 | 436 | 1275 | 419 | 4668 | 2750 | 12841 | 832 | 419 | 32409 | ||

| 1907 | 2819 | 9711 | 931 | 23703 | 0 | 70 | 166 | 422 | 4103 | 2889 | 9877 | 931 | 422 | 27806 | ||

| 1908 | 2565 | 7629 | 710 | 20015 | 0 | 90 | 462 | 371 | 3207 | 2655 | 8091 | 710 | 371 | 23222 | ||

| 1909 | 1919 | 8461 | 792 | 16664 | 0 | 140 | 0 | 230 | 2430 | 2059 | 8461 | 792 | 230 | 19094 | ||

| 1910 | 3113 | 9507 | 651 | 25157 | 0 | 210 | 0 | 611 | 2419 | 3323 | 9507 | 651 | 611 | 27576 | ||

| 1911 | 2040 | 7353 | 546 | 32171 | 0 | 322 | 127 | 697 | 3040 | 2362 | 7480 | 546 | 697 | 35211 | ||

| 1912 | 1158 | 7108 | 440 | 41042 | 0 | 157 | 101 | 231 | 2545 | 1315 | 7209 | 440 | 231 | 43587 | ||

| 1913 | 774 | 5546 | 634 | 40477 | 0 | 58 | 0 | 218 | 4433 | 832 | 5546 | 634 | 218 | 44910 | ||

| 1914 | 1580 | 4207 | 169 | 39679 | 0 | 81 | 0 | 142 | 5320 | 1661 | 4207 | 169 | 142 | 44999 | ||

| 1915 | 583 | 2636 | 145 | 31530 | 0 | 121 | 2 | 112 | 5251 | 704 | 2638 | 145 | 112 | 36781 | ||

| 1916 | 39 | 1416 | 115 | 29335 | 0 | 54 | 0 | 98 | 1988 | 93 | 1416 | 115 | 98 | 31323 | ||

| 1917 | 63 | 913 | 57 | 25198 | 0 | 10 | 19 | 91 | 1885 | 73 | 932 | 57 | 91 | 27083 | ||

| 1918 | 67 | 1005 | 81 | 23776 | 0 | 15 | 8 | 93 | 957 | 82 | 1013 | 81 | 93 | 24733 | ||

| 1919 | 14 | 798 | 46 | 23582 | 0 | 35 | 6 | 206 | 2059 | 49 | 804 | 46 | 206 | 25641 | ||

| 1920 | 7 | 1645 | 57 | 26703 | 0 | 53 | 0 | 260 | 3089 | 60 | 1645 | 57 | 260 | 29792 | ||

| 1921 | 360 | 1610 | 273 | 23194 | 0 | 88 | 11 | 241 | 891 | 448 | 1621 | 273 | 241 | 24085 | ||

| 1922 | 334 | 2161 | 141 | 33646 | 0 | 56 | 1 | 149 | 1142 | 390 | 2162 | 141 | 149 | 34788 | ||

| 1923 | 314 | 6675 | 88 | 36772 | 0 | 34 | 15 | 112 | 2026 | 348 | 6690 | 88 | 112 | 38798 | ||

| 1924 | 246 | 3446 | 48 | 30647 | 0 | 39 | 0 | 152 | 1760 | 285 | 3446 | 48 | 152 | 32407 | ||

| 1925 | 429 | 3563 | 97 | 36785 | 0 | 48 | 15 | 148 | 1250 | 477 | 3578 | 97 | 148 | 38035 | ||

| 1926 | 283 | 2610 | 67 | 32894 | 0 | 139 | 11 | 203 | 1080 | 422 | 2621 | 67 | 203 | 33974 | ||

| 1927 | 257 | 2698 | 31 | 35588 | 0 | 616 | 0 | 214 | 272 | 873 | 2698 | 31 | 214 | 35860 | ||

| 1928 | 238 | 2528 | 28 | 37634 | 0 | 0 | 25 | 256 | 423 | 238 | 2553 | 28 | 256 | 38057 | ||

| 1929 | 185 | 2537 | 39 | 31954 | 0 | 64 | 0 | 305 | 475 | 249 | 2537 | 39 | 305 | 32429 | ||

| 1930 | 181 | 3819 | 74 | 33594 | 0 | 76 | 10 | 445 | 267 | 257 | 3829 | 74 | 445 | 33861 | ||

| 1931 | 442 | 2920 | 89 | 32353 | 0 | 22 | 12 | 669 | 284 | 464 | 2932 | 89 | 669 | 32637 | ||

| 1932 | 202 | 2316 | 72 | 33312 | 0 | 34 | 0 | 708 | 176 | 236 | 2316 | 72 | 708 | 33488 | ||

| 1933 | 226 | 3440 | 78 | 34957 | 0 | 21 | 12 | 492 | 234 | 247 | 3452 | 78 | 492 | 35191 | ||

| 1934 | 336 | 2878 | 84 | 35474 | 0 | 71 | 0 | 79 | 119 | 407 | 2878 | 84 | 79 | 35593 | ||

| 1935 | 344 | 3005 | 131 | 37727 | 0 | 68 | 1 | 680 | 219 | 412 | 3006 | 131 | 680 | 37946 | ||

| 1936 | 797 | 3720 | 125 | 47729 | 0 | 125 | 440 | 818 | 440 | 922 | 4160 | 125 | 818 | 48169 | ||

| 1937 | 860 | 3803 | 189 | 50645 | 1158 | 90 | 326 | 465 | 289 | 950 | 4129 | 189 | 465 | 52092 | ||

| 1938 | 216 | 3693 | 80 | 48962 | 1739 | 30 | 68 | 171 | 171 | 246 | 3761 | 80 | 171 | 50872 | ||

| 1939 | 34 | 3212 | 114 | 56166 | 1962 | 9 | 74 | 483 | 495 | 43 | 3286 | 114 | 483 | 58623 | ||

| 1940 | 83 | 2566 | 19 | 46408 | 2455 | 5 | 88 | 406 | 670 | 88 | 2654 | 19 | 406 | 49533 | ||

| 1941 | 10 | 1440 | 10 | 41480 | 2150 | 10 | 96 | 494 | 47 | 20 | 1536 | 10 | 494 | 43677 | ||

| 1942 | 0 | 1251 | 0 | 35379 | 2624 | 9 | 153 | 414 | 1830 | 9 | 1404 | 0 | 414 | 39833 | ||

| 1943 | 0 | 716 | 0 | 31603 | 1920 | 0 | 268 | 354 | 45 | 0 | 984 | 0 | 354 | 33568 | ||

| 1944 | 0 | 777 | 0 | 29805 | 1559 | 0 | 0 | 309 | 0 | 0 | 777 | 0 | 309 | 31364 | ||

| 1945 | 0 | 497 | 0 | 23509 | 1460 | 0 | 221 | 251 | 8252 | 0 | 718 | 0 | 251 | 33221 | ||

| 1946 | 0 | 193 | 0 | 1371 | 130 | 0 | 538 | 313 | 35290 | 0 | 731 | 0 | 313 | 36791 | ||

| 1947 | 0 | 0 | 0 | 0 | 0 | 0 | 723 | 298 | 37025 | 0 | 723 | 0 | 298 | 37025 | ||

| 1948 | 0 | 0 | 0 | 0 | 0 | 0 | 572 | 213 | 27817 | 0 | 572 | 0 | 213 | 27817 | ||

| 1949 | 0 | 0 | 0 | 0 | 0 | 0 | 160 | 62 | 6967 | 0 | 160 | 0 | 62 | 6967 | ||

It is noticeable that, particularly in the earlier period, a large proportion of the lime and cement sold was not made by Nelsons. The majority of these materials were sold at remote sales points, particularly London, and were packed under the Cock logo by other producers - mainly the other Warwickshire producers.

The total tonnage produced on site varied remarkably little during the period, and never rose very much above the 40,000 tonnes capacity in 1886. However, the amount of lime in the mix consistently fell. It is noticeable that lime production was set aside during both World Wars. Other Blue Lias Lime producers ceased manufacture earlier: Rugby in 1932, Barrow and Southam in 1935, Barnstone in 1938, Aberthaw and Harbury in 1939.