The 1889 annual meeting of the British Association for the Advancement of Science was held in Newcastle Upon Tyne. In addition to the Proceedings (which are available on the internet), a supplement was published describing the industries of the area. Two of the chapters were concerning the cement industry. The following is a transcript of these chapters, appearing on pages 207-218. Both authors were employees of I. C. Johnson & Co. Ltd., which was by far the largest manufacturer in the Tyne/Tees region.

Cement

by John Watson (Note 1)

The cement industry in the North of England has for many years been almost exclusively confined to the manufacture of Portland cement.

When the production of cement was first introduced into this district, Roman and other hydraulic cements were manufactured on the Tyne in addition to Portland, but whilst the production of the latter has largely increased the former have ceased to exist as articles of manufacture. The reason for the development of one branch of the cement industry to the almost entire exclusion of others is easily explained. Roman, Mulgrave (Note 2), and other well-known cements, which formerly were thought equal, if not superior, to Portland cement, are produced from natural rock, and the component parts being already in chemical combination, no variation to suit the purposes for which the cement is required is possible. Portland cement, on the other hand, is an artificial mixture, and, aided by chemical knowledge, the manufacturer, by varying the proportion of the raw materials, can produce a finished material suitable for all purposes, and far exceeding in value and utility the cements produced from natural stone (Note 3).

Whilst the production of Portland cement has been increasing so rapidly the alterations and improvements in the process of manufacture have been numerous and important.

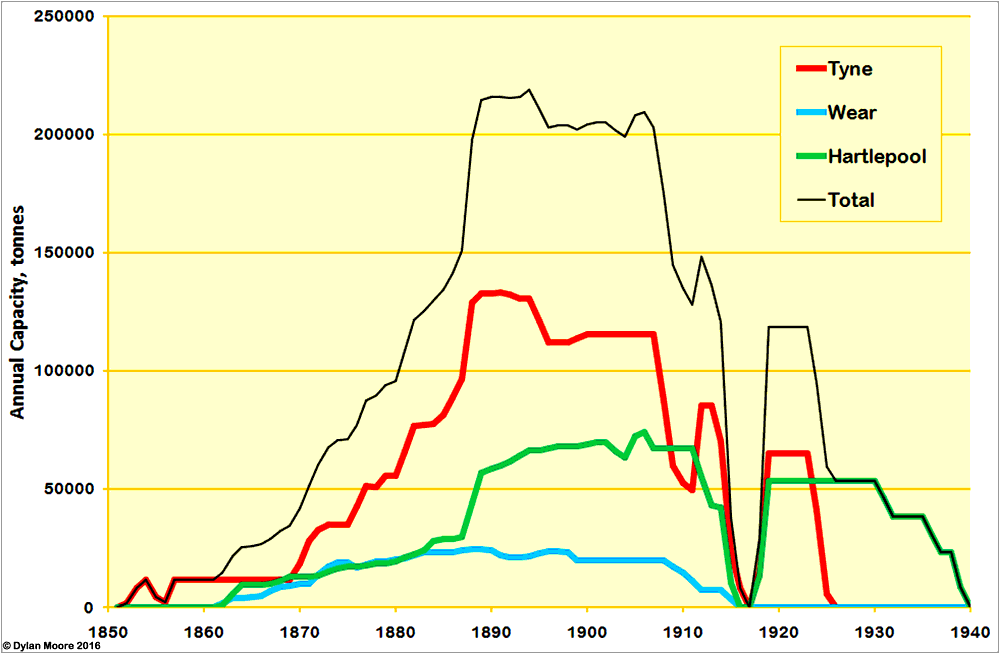

The following statistics show the estimated state of the cement industry in the North of England last year as compared with the year 1863 (Note 4):—

| TYNE.—CEMENT MANUFACTURED. | ||

| 1863 | 1888 | |

| Portland cement | 10,000 tons | 120,000 tons |

| Roman cement | 350 tons | Nil |

| WEAR.—CEMENT MANUFACTURED. | ||

| 1863 | 1888 | |

| Portland cement | 2,000 tons | 25,000 tons |

| HARTLEPOOL.—CEMENT MANUFACTURED. | ||

| 1863 | 1888 | |

| Portland cement | 4,000 tons | 32,000 tons |

The raw materials employed in this district are the same as when the manufacture was established, but the treatment of the materials has undergone considerable changes. In the preliminary stage of manufacture, formerly the raw materials were reduced and mechanically amalgamated, preparatory to the chemical combination by calcination, by the well-known process of the wash mill, and subsequent settlement, called the "wet method", a long and tedious process requiring some months to accomplish, and a large amount of ground space. Goreham's wet grinding or "semi-wet method" has almost entirely taken the place of the old-fashioned wet system. Besides economy of space and rapidity of manufacture, a more perfect amalgamation of the raw materials is also obtained by the "Goreham's process".

The burning of Portland cement is a very important branch in the manufacture, and many novel arrangements have been tried and adopted with varying success in order to secure more perfect calcination, combined with economy of fuel.

Whilst some of the cement makers in the North of England have not deemed the improvements introduced in connection with the burning of sufficient importance to induce them to alter from the old-fashioned mode of burning by open topped kilns, others have adopted the methods introduced with undoubted success. Johnson's patent chamber kiln has been extensively adopted in this district, four out of the seven manufactories on the Tyne being worked almost exclusively on that system of burning, as well as one of the two cement works at Hartlepool (Note 5).

The ordinary cement kiln, as well as Johnson's chamber kiln, are intermittent in their working, and several attempts have been tried to introduce a continuous cement kiln. The only successful type of a continuous kiln in this district is the Dietzsch kiln recently erected at the works of Messrs. Trechmann at Hartlepool. Besides being continuous, the inventor of this kiln claims the advantage of being able to use small coal for calcining, and utilizing to the fullest capacity the products of combustion contained in the fuel (Note 6).

The last stage in the manufacture of cement, that of grinding, has not undergone much change for some years as regards the machinery and appliances employed — French burr millstones having outlived numerous novel appliances that have been tried for reducing cement to the requisite fineness. Messrs. Potter, of the Tyne Cement Works, Willington, have recently patented an improvement in millstones for grinding cement. The millstones are a combination of burr and rock emery, and the advantages claimed, as compared with burr stones, are that they grind finer without additional power, whilst they wear as long and require much less attention, as dressing is almost entirely dispensed with (Note 7).

Although the appliances for grinding Portland cement have not altered much, the degree of fineness of the finished material has reached a much higher standard, and some makers in the North of England are now producing an article of such a degree of fineness that would not have been thought possible a few years ago. This important attainment has been fully appreciated by engineers and others who are aware of the fact that the finer Portland cement is ground the more valuable it becomes, providing, of course, it also contains the other essential properties of good cement, and the attention the cement makers in the North of England have recently given to this important feature of fine grinding, combined with the introduction of chemical principles in the process of manufacture, has largely contributed to increase the demand and establish the reputation of Portland cement.

In his search for a mortar for the foundation of the Eddystone Lighthouse in 1756, John Smeaton found that by adding clay to chalk or lime (Note 9), calcining and pulverising the resulting mixture, he obtained what he required, viz., a mortar rapidly hardening and able to resist the solvent force of water when immersed therein. He thus in laying the foundation of this famous lighthouse laid the foundation of all that has since been done in the knowledge and manufacture of cements and hydraulic mortars. The first practical outcome of Smeaton's discovery was obtained by Parker in 1796 (Note 10), who, collecting the nodular septaria of the London clay. from the beaches of Kent and Essex, reduced the same to a calcined powder of strongly cementitious properties, and founded the "Roman" cement industry of the South of England.

This industry between 1800-25 became an important one, and had its principal seat on the Thames, in London, and at Northfleet, and during the same period careful investigations were made on cement by General Pasley in England, and Vicat in France. It was early seen that the supply of septaria was limited, and considerable anxiety was felt to replace it by some artificial compound, and thus find further supplies of the new and valuable constructive material. They succeeded in forming the necessary admixture, but singularly enough, after its calcination, put aside as useless the only portion of it having the necessary properties. It remained for a Yorkshire bricklayer to show them that the partially vitrified "clinker" so carefully rejected was the true cement. In 1824 he obtained letters patent for "Portland" cement, and he is without doubt the real inventor of the material. It is said he stumbled on the discovery in burning some debris on a heap of limestone-clay road sweepings (Note 11). The surface of the heap clinkered, and after rain hardened into stone. His specification confirms the tradition, for he says: "I take a specific quantity of limestone such as that generally used for making or repairing roads, and I take from the roads after it is reduced to a puddle or powder".

Aspdin began the manufacture in Wakefield, and his works are still in existence and in operation there (Note 12). His discovery was then introduced to the Roman cement makers of the Thames by his son William. It took root and gradually superseded the older cement. William Aspdin came north and started the manufacture on the Tyne about 35 years ago (Note 13), and thence has sprung the entire northern cement industry. His business soon passed into other hands (Note 14), more cement works were started on the Tyne, the Wear, and at Hartlepool, and in 1863, the year of the last visit of the British Association to Newcastle, 16,000 tons a year were produced. Since then the trade has immensely expanded. The present production is 180,000 tons annually (Note 15), an increase of 1,100 per cent. from works now covering over 80 acres, finding employment for a large number of hands, with capital of about £300,000, and using millions of feet of timber for casks, and upwards of 600,000 tons a year of raw materials in the shape of chalk, clay, coke, coals, etc., as well as benefiting largely numerous auxiliary trades. It has so far followed the demand, and hence there has been no over-production. The visitor will find some excellent examples of the uses of cement in the concrete of the Tyne piers (built of concrete blocks), in the harbour works of the Tees and the Wear and at North Sunderland (monolithic in situ), and a very fine example of monolithic in situ concrete (by J. Watt Sandeman) in the graving docks at Blyth.

It was thought at one time that cement could be made only from London chalk and Medway clay. Chemical analysis and German chemists soon dispelled that illusion. The Germans did not rest there, but straightway set about extracting from their own raw materials, in many cases differing widely from the English, the necessary constituents to form Portland cement. They succeeded, and have at the same time developed one of the most important industries in the German Empire. Their scientific research has had most important results, and well illustrates the value of science to manufactures and trade. As soon as it was seen that the mysterious compound was not a mixture of London chalk and Medway clay, but a double silicate of lime and alumina of practically unvarying composition, the matter was taken up in almost every country in Europe, with the result that all over the Continent cement works have come into operation, finding raw materials in various forms, but all attaining in the finished product the necessary chemical composition.

To this influence also is due the "dream" of the northern cement industry: that out of the refuse blast furnace slag (of which Middlesbro' alone makes thousands of tons every week), Portland cement may some day be made. Its constituents are similar to those in cement, and years of patient investigation by Mr. Charles Wood, of Middlesbro', and others, and some striking results recently obtained by German chemists, have led to the belief that this dream may before long be realised. It is proved that a mixture of hydrated lime and dry granular slag-sand thoroughly pulverised gives a substance of extraordinary cementation value, and similar in many respects to Portland cement (Note 16). Its main difficulty at the moment is that when kept for a length of time in a powdered state exposed to the atmosphere it rapidly absorbs CO2, and its cementitious properties weaken. As a cement in practical construction time is required for an opinion to be formed. It is now under test at Loftus, in Cleveland, where the Skinningrove pier (Note 17) has been constructed with this material. Mr. Stead, of Middlesbro', has made some interesting experiments with slag-cement, and appended are results of his analyses. The success of this new departure would mean a veritable revolution in the cement industry, in which under any circumstances the North of England would be secure. The seats of the present manufacture would be shifted to the iron producing districts, and the entire export and home supplies recast.

As it is the northern industry is dependent on the Thames for its supply of calcium carbonate in the shape of chalk. This is brought by sailing colliers as ballast on their voyage to load coals here. Now these colliers are gradually being replaced by steamers, and consequently the future chalk supply has been always a source of anxiety. One can therefore understand with what interest makers are following the development of the opportune discovery of Mr. Chance for the recovery of sulphur from alkali waste. A. stream of CO2, is pumped through mixture of alkali waste and water with the result that sulphur is set free and calcium carbonate precipitated.

The CaCO3 thus remaining promises to be of sufficient purity, and in such a form as to be well adapted for cement making. From a similar material cement is now being made by the Widnes Alkali Company (Note 18). The Newcastle Chemical Works Company, Limited, have put down most extensive plant for the recovery of sulphur by this process, and they will have residual CaCO3 to the extent of about 1,800 tons a week to dispose of. The Jarrow Chemical Company have also laid down plant (Note 19), and it is hoped that eventually the Tyne cement trade will have at their doors a regular and efficient auxiliary supply of a raw material well adapted for their purposes, a supply the continuance of which from the south the future did not seem to favour.

There followed a large amount of analytical data on raw materials, but they are of poor quality and not worth recording here.

By the time of the article, the region's capacity had reached its maximum, further expansion being curtailed by the rising cost of chalk brought from Kent and Essex, and 20 years later, a concerted campaign by the efficient southern plants pushed most of the northern firms out of business. In the end, the one remaining plant was

By the time of the article, the region's capacity had reached its maximum, further expansion being curtailed by the rising cost of chalk brought from Kent and Essex, and 20 years later, a concerted campaign by the efficient southern plants pushed most of the northern firms out of business. In the end, the one remaining plant was