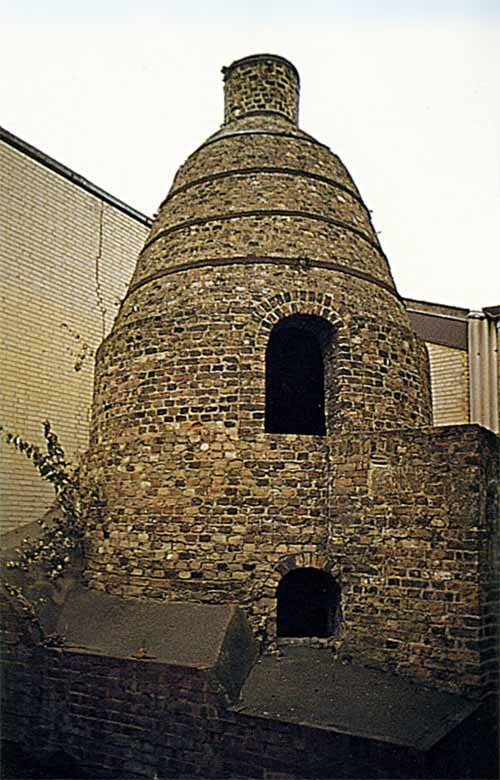

Robins' Kiln

The manufacture of modern Portland cement began with arrival in the south of England of William Aspdin, son of the owner of the original 1824 patent. The history of this period has been recorded by Davis (1924), Halstead (1961) and by Francis (1977).

William Aspdin (b 23 September 1815, Leeds, W. Yorks) worked for his father's firm in Wakefield for about 12 years before leaving for London abruptly in July 1841. After a short period (1842-1846) of manufacturing cement at Rotherhithe, Aspdin relocated to Northfleet (Note 1), taking the site of James Parker's original Roman cement works at the Northfleet Creek tidal mill. The new venture was underwritten by a partnership - Maude, Jones and Aspdin. This partnership went bankrupt on 5 June 1847. Aspdin set up a new partnership and on 1 January 1848 the works was acquired by Robins, Aspdin & Co. (Note 2)

William Lewen Tugwell Robins was born around 1782 at Tetbury, Gloucs. Having qualified as a solicitor, he lived in Holborn, and then in Hammersmith until his death on 18 September 1869 (Francis says 1868). He appears not to have performed an active role in the partnership, although in the 1851 and 1861 censuses he described himself as a cement manufacturer (Note 3). The partnership also included George Henry Goodwin (b 8 February 1810, Hildersham, Cambs) who had married Robins' daughter Emma.

The Parker & Wyatt cement works spanned Northfleet Creek and was centred on the tidal mill that was used to grind Roman cement. On arrival, Aspdin immediately commenced setting up a steam-powered mill 160 m to the east on the south side of the creek. His cement works was arranged for the special requirements of Portland cement manufacture: a chalk quarry in the rising ground to the south, washmills for grinding the slurry, then progressively northwards:

- slurry backs for settling the slurry

- drying flats for drying the settled slurry

- a bank of kilns for burning the dried slurry

- finally, the steam-powered mill for grinding the clinker.

Goodwin left the partnership in March 1849. On 19 January 1850, John Henry Cox joined the partnership (Note 4). In 1851, Cox discovered misappropriations typical of Aspdin's business dealings, and brought an action in Chancery (Cause 1851C156) to dissolve the partnership, also obtaining an injunction excluding Aspdin from further dealings with the business. These had effect from 7 November 1851, and this date unambiguously defines the end of Aspdin's involvement with the Northfleet site (Note 5).

After this, Aspdin initially spent some time consulting for Thomas Sturge in the setting up of the adjacent cement works later known as Bevans (Note 6). His career then continued as a series of short periods of involvement with various naive and ultimately disappointed investors. He set up a new partnership with Augustus William Ord (b 1828, Manchester) who financed the construction of a much bigger works at Gateshead, to which place he moved with his family in 1852 (Note 7). Although fifteen kilns were constructed, the firm went bankrupt 17 April 1855. While still un-discharged, Aspdin formed in 1856 a new partnership with William Jackson (Note 8) and a built a three-kiln works at Ouseburn, over the river. This partnership was dissolved in April 1857, and Aspdin, with at least three sets of creditors chasing him, fled with his family to Hamburg (Note 9). The North Shields coal merchant who arranged his passage also financed the construction of a cement works at Altona, using ballast chalk. This lasted less than a year. He then fell in with Edward Fewer, an Irish merchant living in Altona, who financed purchase of chalk land at Lägerdorf and the construction of a kiln. He fell out with Fewer within a year. Moving to Itzehoe, his last act was to provide consultancy to Gustav Ludwig Alsen in setting up his cement works there. He was killed in a street accident on 11 April 1864 (Note 10).

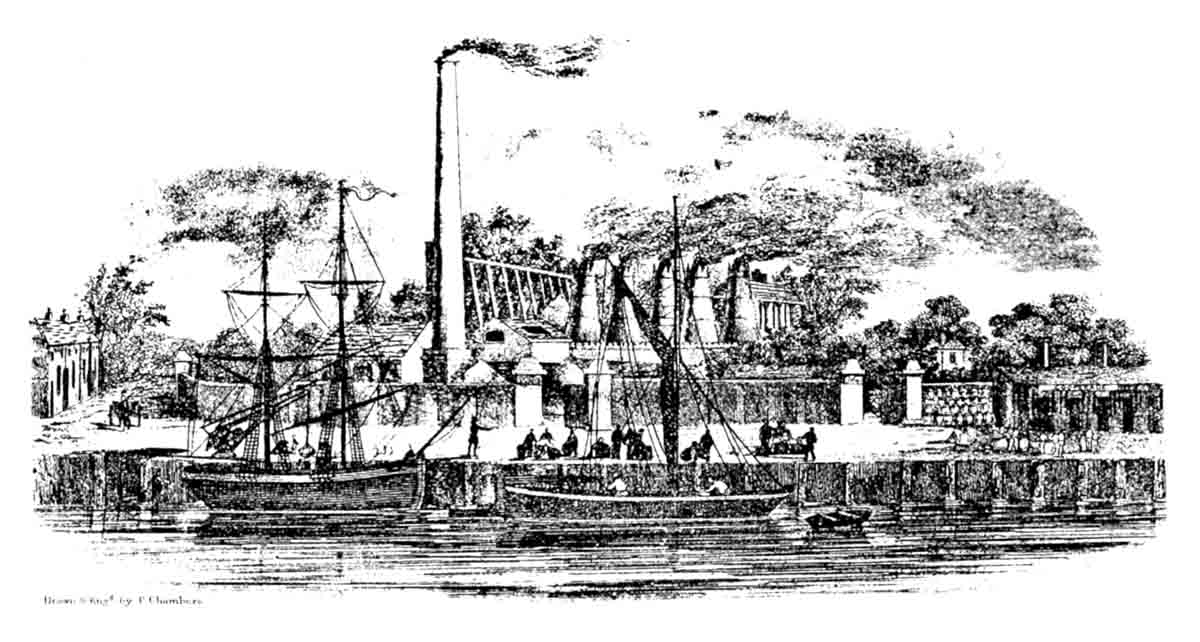

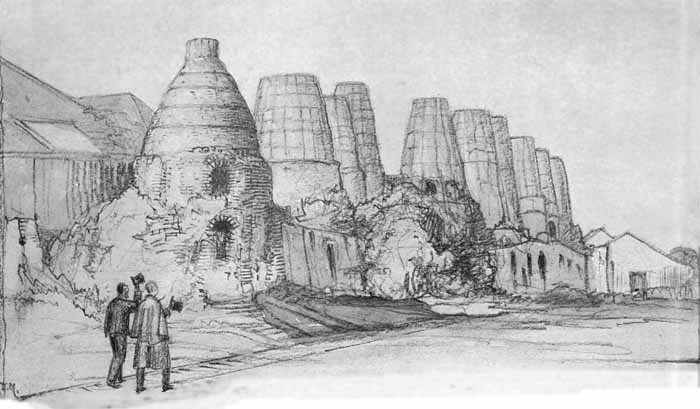

Figure 1. Robins' kilns in the early 1850s

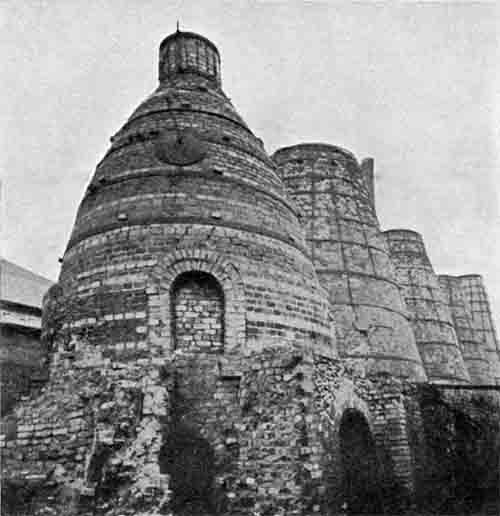

Figure 2. Kilns built by Aspdin at Gateshead

Back at Northfleet, after the ousting of Aspdin in 1851, Robins and Cox formed a new partnership and a company entitled Robins & Co. (Note 11) There exists a print of the works (Fig. 1) shortly after the new company formed; it appears to be as Aspdin left it, showing the view from the other (north) side of the creek. Five kilns were erected, and were of William Aspdin's characteristic design: an eggcup-shaped, firebrick-lined burning chamber of 11 feet diameter, surmounted by a conical bottle extension to increase the draught constructed from nine-inch brickwork. On top was a narrow cylindrical chimney-section surmounted with a crown-fringed chimney pot.

It is interesting to compare these kilns with those constructed by Aspdin in his next project at Gateshead (Fig. 2). These have the same characteristic conical shape and top.

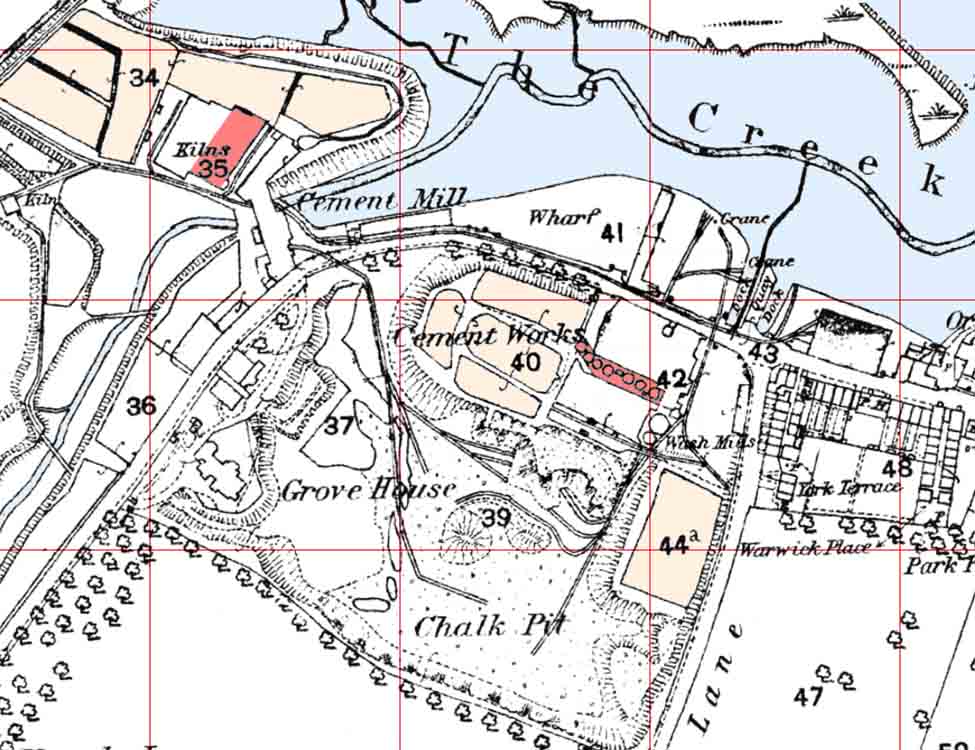

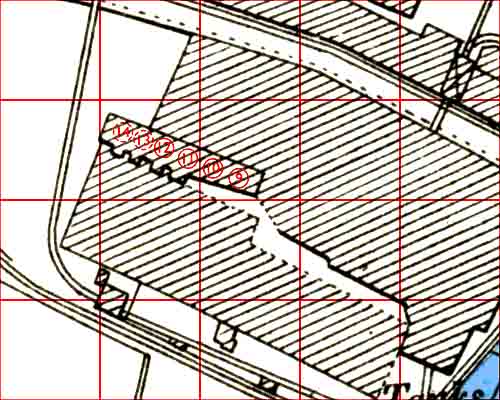

Figure 3. OS County Series 1st Edition map surveyed 1863-4. Map base courtesy of National Library of Scotland.

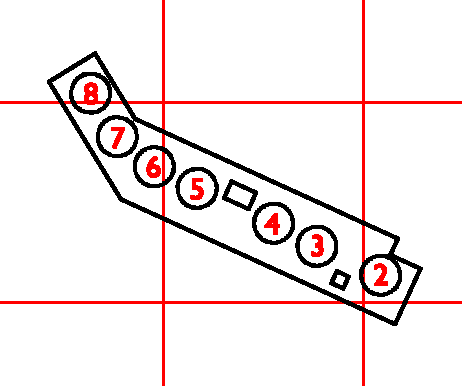

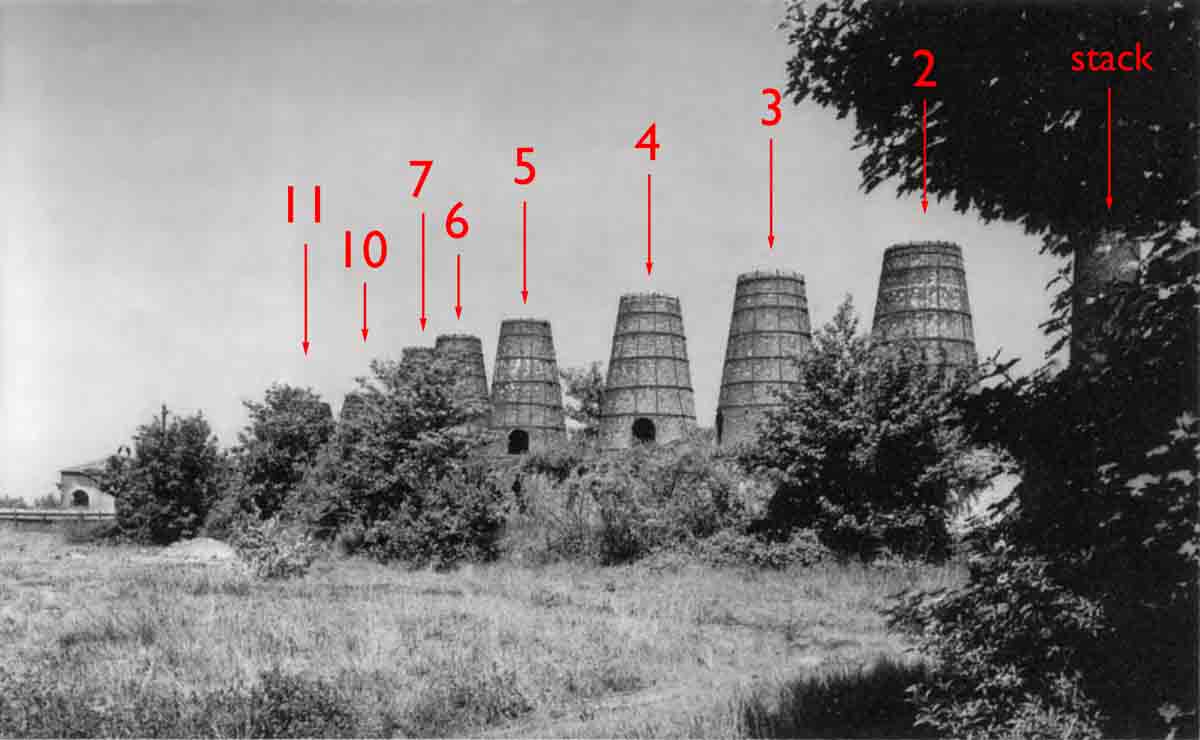

Figure 4. The 1863 kiln bank with arbitrary numbering

Figure 5. OS County Series 2nd Edition map surveyed 1895. Map base courtesy of National Library of Scotland.

Figure 6. 1926 drawing by Donald Maxwell

Figure 8. Robins kiln 9 in the early 1920s

Figure 7. Robins kilns from the west - 1920s

Evidently, the works was expanded during the following 12-13 years, as evidenced by the first edition County Series Ordnance Survey map (Note 12). This was surveyed 1863-1864, and shows a bank of ?six bottle kilns, complete with slurry backs and drying flats, on the north side of the creek, and on the south side (Fig. 3) an irregular bank of kilns. Arranged around these are:

- to the north-east, the steam-powered finish mill as shown in the print, complete with stack

- to the south-east, washmills

- south of them, a large slurry back

- south of the kilns, drying flats

- to the west, four smaller slurry backs

The interpretation of the map is aided by the existence of a later impression, published 1876, containing no new surveyed detail, but with the plate re-cut and showing shading of buildings and sharpening of form lines.

The kiln bank shown (Fig. 4) has seven kilns: there may have been an earlier kiln at the east end.

Unfortunately, it was not until 1895 that the Ordnance Survey map was re-surveyed (Fig. 5). It shows no individual kilns, but the kiln bank had been extended westwards over an area previously occupied by slurry backs. The size of this extension suggests another six kilns had been built. However, the major extension of the plant had been north of the creek, with the installation of chamber kilns, and it was that part of the plant that remained in operation into the 20th century. It looks as though the bottle kiln bank extension was built during the late 1860s, and the whole kiln bank was abandoned in the early 1870s.

The kiln bank was extended with a dog-leg turn, presumably so that the extension could be built on the relatively un-disturbed ground between the original slurry backs. This feature aids identification of individual kilns in their pictures. Unlike the newer parts of Robins Works to the north of the creek, the old kiln bank remained in place for many years after the closure of the works around 1910. In the 1920s, the centenary of Joseph Aspdin's patent stimulated international interest in the kiln bank as a historical monument, and many photographs were taken during the period. A 1926 drawing by Donald Maxwell (Fig. 6) shows the whole bank, viewed from the west. The nearest complete kiln is No.12, which had a distinctive bee-hive shape, unlike the conical shape of the others. At the far end are the Aspdin kilns (or, at least, kilns occupying the positions of the Aspdin kilns). The conjectured kilns 13 and 14 are represented only by a pile of rubble.

A 1920s photograph (Fig.7) has appeared in many texts and it shows the western extension kilns, also from the west. In the rubble in the foreground, a distinct curved section of the hearth of the thirteenth kiln can be made out. Behind this are kilns 12, 11, 10, 9 and kiln 8 in the "dog-leg".

Also appearing in many texts is a fairly good quality image of kiln 9 (Fig. 8). The "dog-leg" in the kiln bank is visible on the right. A. C. Davis, in his books and articles (starting 1929) (Note 13), labelled this picture "Early Kiln used by Aspdin's Son at Northfleet". This is the first suggestion that these kilns were associated with William Aspdin. As is explained in the timeline above, this kiln was constructed after 1863, and William Aspdin departed in 1851, so this claim is clearly false - in fact the kiln may have been constructed after Aspdin's death.

Figure 9. Robins' kilns - late 1930s? - from the south-east

Another picture was taken later - perhaps the late 1930s, or even later (Fig. 9). It shows the kiln bank from the south-east, with the Aspdin kilns (or their successors) nearest. The "dog-leg" section is hidden behind kiln 7, and the beehive-shaped kiln 12 is hidden by bushes. The old power-house stack still stands on the right. The building on the far left is one of the warehouses on the north side of the creek. All these features were still shown on the 1953 National Grid 1:1250 Ordnance Survey map, and continued in place in revisions as late as 1966, but on the 1971 map, the area had been re-developed in essentially its present (2019) state. The only kiln remaining was now the beehive-shaped Kiln 12.

Kiln 12 is the kiln preserved as a scheduled ancient monument today. It would appear that Kilns 2-11, including all the Aspdin kilns, were demolished during the late 1950s. The only evidence now surviving of genuine Aspdin kilns is a set of accurate 1:12 scale models of Kiln 2 that were made at the time of the Aspdin centenary in 1924.

The preserved Kiln 12 was restored in the 1980s and "re-opened" by Sir John Milne, chairman of Blue Circle. The kiln base bears a plaque saying:

THE EARLIEST KNOWN

PORTLAND CEMENT KILN

BUILT AND WORKED BY

WILLIAM ASPDIN

c. 1845

Of course, as has been demonstrated at length above, the kiln was constructed long after Aspdin left. Presumably this plaque was added either during the demolition of the Aspdin kilns in the 1950s or during the later restoration. The true status of the kiln was known to many at the time, and it is clear that the instigators of the restoration were well aware of the falseness of this claim.

Because of the proven much later date of this kiln, the claim that it is the world's oldest must be open to challenge, since other Portland cement kilns from the late 1860s are probably extant. A number of kilns dating from the 1850s were recently (2022) demolished.

The Historic England document describes the scheduled monument. The description states that the kiln (which is certainly different from the other kilns) is a down-draught kiln, as is commonly used for firing bricks, tiles and ceramics. A recent (2021) visit confirmed that this description is incorrect; the kiln is a normal up-draught cement kiln. Unfortunately the Historic England description has been quoted by many spin-off websites. Requests to get the description changed have as yet (7/2022) had no result.