The following are transcripts of two articles that appeared in The Engineer, describing the Nine Elms plant and the Cliffe Quarry plant when they were under the control of Vitale de Michele. The text of both was undoubtedly mainly supplied by Michele and was clearly an exercise in self-promotion, but it is considerably more technically informative than most plant descriptions of the time. The first article was in volume 47, 14/3/1879, p 186, and described Michele's adaptation of I. C. Johnson's kilns at Cliffe Quarry, which had recently been acquired by Francis & Co. His new design for washmills had also been installed at that site.

Michele's Portland Cement Making Plant

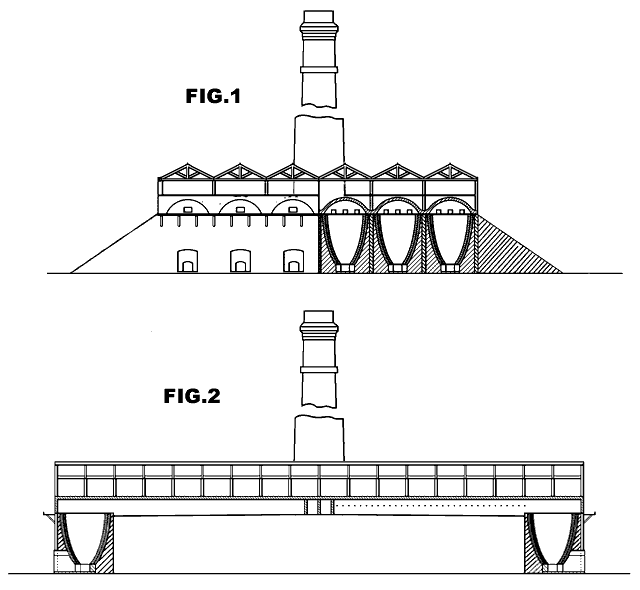

Figures 1 and 2 of our illustrations represent a set of twelve of Johnson's chamber kilns (Note 1), used in the manufacture of cement, and as improved by Mr. V. D. Michele (Note 2). They are arranged back to back, six of the drawing kilns face one way and six the other, the patent chambers running towards each other and meeting in the centre where they are all connected with a brick chimney, 200ft. in height, by means of flues running parallel to the lines of kilns. The kilns are of the ordinary construction, but instead of being surmounted by domes with openings in their centres, they are arched over with bricks on end. This arch, which is thus 9in. thick, is carried along in one direction, and supported by concrete piers which are filled round with ground work. The chambers thus formed are 65ft. long and 5ft. high in the centre, and 15ft. wide (Note 3). They are each connected with the chimney flue by three small openings 1 ft. square, fitted with dampers. Besides these openings in each, there are four at the upper part, circular in form and 1ft. 6in. in diameter in their tops, for purposes of ventilation, and four small square openings in their sides, fitted with light valves, for the admission of the material to be dried in them. There is also an opening in the front of each for introducing coke. A light roof may be thrown over the whole to keep off the rain (Note 4). The action of the chambers may be thus described:— The kiln having received its charge of dried material and coke, the "slurry"—or chalk and clay, with about 40 per cent. of water—as pumped up from the mixing mill, is allowed to run into the spaces between low walls which divide the kilns and the arches of the chamber. When these spaces are full the valves in the sides of the chamber are drawn up, and the material rushes in and form a layer about 16in. thick all over the floor. The whole of the material will not, however, flow, as in the state in which it is pumped up it soon consolidates, and what is left behind is therefore then thrown up into the outsides of the arch (Note 5). The chamber having been thus loaded, the dampers are raised and the kiln lighted up. When the kiln is burnt off—in less than a week—the "slurry" both inside and outside the chamber is found to have been dried by the waste heat produced by the burning, and there is sufficient of it for the next charge. Thus one charge in the kiln dries material for the next, and so on. The advantages of Johnson's system are that the usual coke ovens which consume a large quantity of fuel are entirely dispensed with, and the waste heat from the kilns is utilised in a practical and economical manner. The Johnson chambers were at first constructed 100ft. long, and all the material was dried within them; but by adopting Mr. Michele's system of drying outside as well as inside, they can be constructed little over half the length, thus occupying about half the space, and as the arches are constructed of very much thinner brickwork the first cost is less than half (Note 6). The kilns are in operation at Messrs. Francis and Co.'s, Cliffe Works.

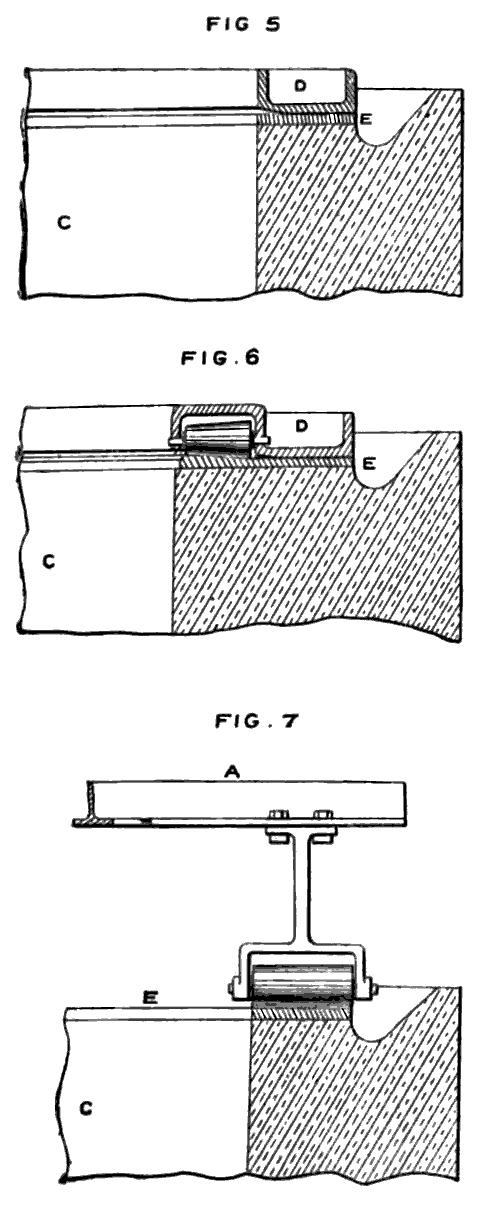

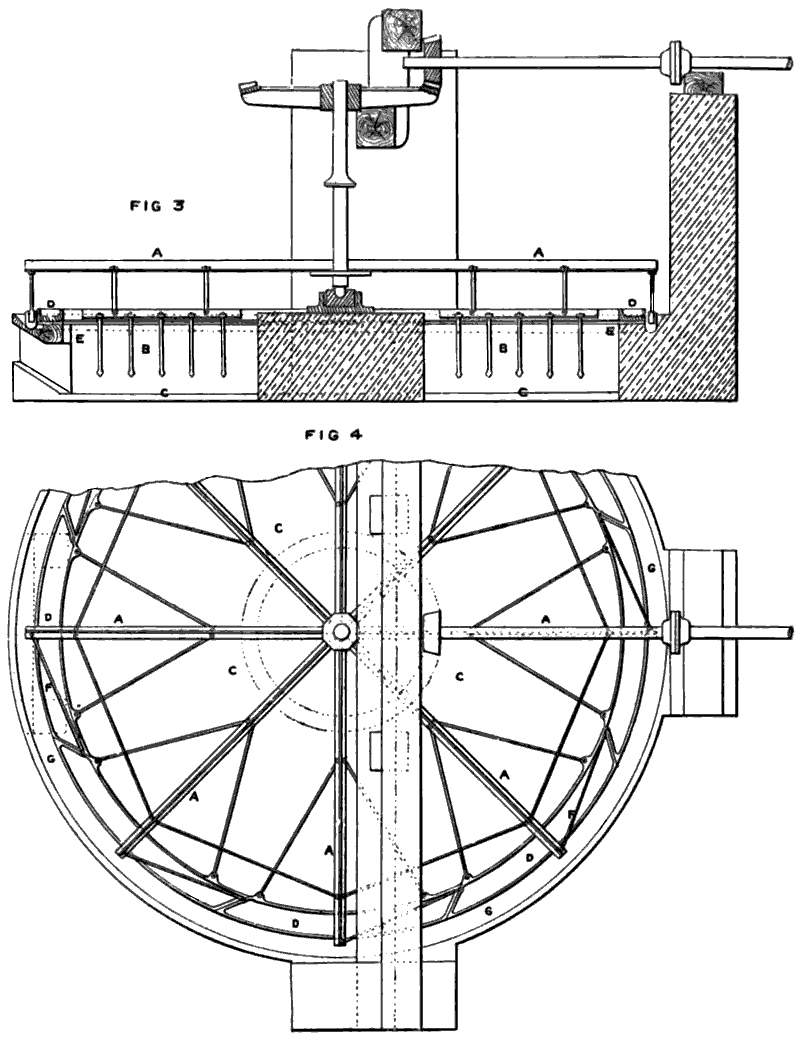

Respecting the wash-mill, Figs. 3 and 4, it may be well to premise that according to the usual method of preparing slurry, from which cement is made, proportionate quantities of chalk and clay are placed in a tank or circular receiver, termed a "wash-mill", in which by agitation and a raking process they are reduced to such a consistency that they will pass through a wire gauze, having about thirty holes to the lineal inch, into settling "backs" or reservoirs, where the solid matter is precipitated, the supernatant water flowing away as it becomes clear. This process requires a long time to complete, as the quantity of water to be removed is large—being that which was added in the wash-mill, or equal to about three times the weight of the material dealt with—and the rate of precipitation is slow.

According to another process of preparing cement slurry, the ingredients are agitated in a reduced quantity of water, and brought to a state of thick sludge in the wash-mill, from which, after passing through a grating with spaces about ½in. wide, the material is lifted to ordinary grinding stones, and by their means reduced to the necessary consistency (Note 7).

Our illustration represents an improved mill, the action of which is as follows:— About 20 per cent. only of water is added to the ingredients, which are reduced in the manner first described in an ordinary wash mill, and as the "slurry" rises over the edge of the pan, it finds its way between cast iron serrated surfaces, which form the rim of the wash mill, and one of which rotates with the mill, and is by them reduced to the necessary consistency (Note 8). After leaving the mill it is at once, without any further treatment, pumped, or allowed to flow to the drying space. Fig. 3 shows a vertical sectional elevation, and Fig. 4 a plan of the apparatus. The arms A, which carry the rakes B in an ordinary wash mill C, are extended, and from their ends is suspended a cast iron grinding plate D, Figs. 5 and 6, which may be made in one piece or built up of segments, united together by bolts, which rotates with and is driven by the arms A, through the intermediation of the rods F. Below is a similar fixed plate E, Fig. 7, which forms the edge of the mill pan, and the cement slurry passes between these surfaces, the lower one of which is stationary, and the upper moving, and when thus reduced to the necessary consistency, falls into the receiving channel G, which conveys it away. The advantages secured by these mills are that the expense of constructing "backs" and the cost of working them, as well as the delay incidental to their use, are saved, as well as the space they occupy. No other machinery is required to prepare the slurry, which can be at once pumped direct from the wash mills to the drying place, containing only about 40 per cent. of water. No miller is required to attend to the plates, which will last a long time, and when worn out are cheaply renewed. The first two of these mills—after the experimental one—which have been at work for some months, showed scarcely any wear after preparing upwards of 4000 tons of material.

The following article appeared in The Engineer, 53, 27/1/1882, pp 57-58. It describes the Nine Elms plant and the Cliffe Quarry plant when they were under the control of Vitale de Michele. The account of Nine Elms describes the operation of an old-fashioned wet process bottle kiln plant in great detail.

MESSRS. FRANCIS AND CO.'S CEMENT WORKS, CLIFFE, KENT.

It may be said that so many books and papers have been published on cement and cement testing during the past few years that there cannot be much more to be said on these subjects. We propose, however, to describe the practical manufacture of cement as carried on at a large works. We recently visited the extensive works of Messrs. Francis and Co. at Cliffe (Note 9), over which we were conducted by Mr. V. D. de Michele, Assoc. M.I.C.E., Westminster, the engineer of the works (Note 2). A greater quantity of cement is made in Kent than in any other district in the world. The manufacture is carried on on the banks of the rivers Thames and Medway, where abundant supplies of the necessary raw materials are found in close proximity, and where the conditions for economic working are very favourable, both as regards making and distribution, communication with London and its docks by river being easy, cheap, and rapid, and where the gasworks of London afford an ample supply of coke—the fuel almost exclusively used in cement works—at a moderate cost.

Messrs. Francis and Co. possess two large works (Note 10), the older of which was originally laid down by Mr. Alfred Giles, C.E., M.P. (Note 11), but were subsequently completed from the designs and under the superintendence of Mr. Michele. These works are situated on the banks of the Thames, near its mouth, where they are surrounded by clay marshes, and are in close proximity to the chalk hills, with which they are connected by a short tramway. The Portland cement is manufactured from chalk and clay, which in this neighbourhood are found in a peculiarly soft, and therefore convenient form for reduction and mixture in a wet state. These materials are delivered from small contractors' tip wagons close together at a convenient point on the works, and are used in the proportion of from two to two and a half chalk to one clay by weight; the proportions are adjusted by the regulation of the number of barrow-loads of chalk to each ten barrow-loads of clay. It is impossible to lay down any fixed rules as to the quantities to be used, as they must vary continually with the changes in density and quality of the materials (Note 12). The greatest care and attention are therefore necessary on the part of the chemist who is employed to analyse and test the different mixtures from day to day, as well as on the part of the foreman whose chief duty it is closely to watch the materials and to regulate the proportions by the help of the information he receives from the chemist, and to see that the barrows are correctly filled and emptied in turn by the men. It may surprise many to learn that the apparently rough-and-ready rule-of-thumb manner of mixing together so many unweighed barrow-loads of material from constant usage in skilled hands should be capable of such nice adjustment, but it is a fact on record that after many days working in this way the samples from the resulting mixtures have not shown so much as one per cent variation in quantity of carbonate of lime (Note 13). For the purpose of, if possible, rendering the proportions still less liable to error, Mr. Michele has lately designed and introduced an apparatus for weighing one barrow of clay against two of chalk, thus also insuring their being always delivered into the mixer in their proper turn. This apparatus is simply a scale with a scale bar of unequal length from point of suspension, and a pair of large flat scale pans, one carrying one and the other two barrows. But although this apparatus is simple in construction and works well, and is of great use as a means of insuring the amalgamation of accurate and even proportions by weight, it is quite useless unless it is adjusted frequently with reference to the constantly varying specific gravities, and compositions of the chalk and clay.

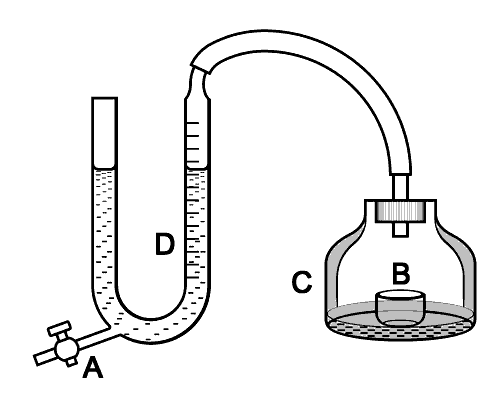

In order to guide the foreman in determining the correct proportions, whether the old barrow system alone, or the new weighing apparatus be employed, daily laboratory tests are made. That which is most frequently repeated is one for ascertaining the carbonate of lime value only of the mixture in its first stage of manufacture. It can be accomplished in a few minutes, and for the purpose an apparatus, designed by Dr. Scheibler, is used (Note 14). It is very simple and effective, and in the hands of a skilled operator will be found of great value to manufacturers. It may be safely predicted that should its use become more general it will contribute in no mean degree towards accelerating the general improvement which is now taking place in the quality of cement manufactured. Its action is briefly this—to cause a given quantity of a material which is partly composed of carbonate of lime, no other carbonates being present (Note 15), to give off its carbonic acid, and then to measure the quantity. The exact amount of carbonic acid having been arrived at, the percentage of carbonate of lime is also known, as it is a substance of definite composition, its constituent parts being 56 per cent. lime, and 44 per cent. carbonic acid. It consists simply of a glass horseshoe tube, graduated on one arm, and a bottle attached to it by an india-rubber pipe. A is a small pipe with a stop in it, to admit water. B is a small vessel which can be dropped in at the neck of the bottle C. D is the graduated horseshoe in air-tight connection with the bottle C. The mode of operation is simple. A small quantity of the mixed chalk and clay is thoroughly dried. A given quantity of this is weighed and put into the vessel B. A little acid is put into the bottle C. B is lowered into C in such a manner that the acid and "slurry" do not come into contact. C is corked down. The tube D is filled with water. C is then shaken so that the acid and "slurry" come into contact. As the carbonic acid gas is given off it passes into D, from which the water is let off as the gas enters, so that the heat in both arms is kept equal. The volume of gas given off is then read by the graduations on the tube. Barometrical and thermometrical corrections are then made. As the carbonic acid gas and the lime in chalk bear fixed relations to each other, when the quantity of the gas has been ascertained the quantity of lime is also known, and hence this little apparatus is exceedingly useful in enabling the cement maker to know in a very short time the quantity of carbonate of lime in his mixture.

The following table shows the usual composition of the materials and the products, and exhibits the changes which take place in the constituents after burning, grinding, and mixing with water (Note 16):—

| Clay | Slurry | Cement | Gauged | Cement | |

|---|---|---|---|---|---|

| Sand | 0.87 | 1.24 | 0.98 | 1.16 | 1.28 |

| Silica | 54.14 | 11.77 | 20.45 | 18.77 | 20.73 |

| Peroxide of Iron | 7.76 | 2.13 | 4.37 | 3.08 | 3.40 |

| Alumina | 14.68 | 4.45 | 8.05 | 7.04 | 7.77 |

| Magnesia | - | - | 1.48 | 1.52 | 1.68 |

| Carbonate of Magnesia | 4.48 | 2.87 | - | - | - |

| Lime | - | - | 62.13 | 54.89 | 60.62 |

| Sulphate of Lime | - | - | 2.13 | 1.73 | 1.91 |

| Carbonate of Lime | 2.01 | 69.97 | - | - | - |

| Water, carbonic acid | 15.03 | 5.29 | - | - | - |

| Water | - | - | - | 9.45 | - |

Besides the laboratory tests referred to, samples of the first mixtures of ingredients are carefully taken every day, and these are converted into cement by means of miniature drying floors and grinding appliances. No useful result can be obtained from such experiments, however, in less than from two to three days, and at the expiration of that time the fact of whether there is a dangerous excess of lime or not can only be judged by a further delay of, say, forty-eight hours, whilst the strength at the present usual age cannot be arrived at until nine or ten days after the mixture took place, and, therefore, errors, extending through many hundred tons of material, may have taken place before they are detected. The value of a test for carbonate of lime, which can be made in a few minutes, is therefore obvious. Excess of lime is shown by the samples cracking after immersion in water, in consequence of the expansion of the free lime when wetted. Excess of clay can be detected by the colour and low tensile strength of the cement. At the works under consideration about 75 per cent of carbonate of lime is found to be the best proportion, this quantity being present in the dried samples of the mixture of chalk and clay as it leaves the mixing mills, or wash mills, as they are technically called.

There are in the old works of which we are speaking two of these mills, which are of the usual form, each consisting of a vertical shaft driven by bevel gearing and carrying eight horizontal arms, from which depend four cast iron harrow frames, into which are inserted wrought iron "tines" or teeth, the whole revolving in a brick tank. As the "tines" are driven through the mixture of chalk, clay, and water—the latter element being admitted to the extent of about 300 per cent. of the two former by weight (Note 17)—the materials are disintegrated at the same time that they become thoroughly mixed; continued washing rendering the particles so fine that the motion of the mill carries them along with the water through brass wire gauze sieves containing 30 holes to the lineal or 900 holes to the square inch, these sieves being arranged in such a position at the periphery of the brick tank that the mixture which passes through them may be conveniently removed by pumping and conveyed to the settling reservoirs for precipitation by gravity. The chalk when it is put into the mill contains about 20 per cent of water, and is nearly pure carbonate of lime, containing only about 2 per cent of extraneous manner, principally sand (Note 18). The clay contains about 40 per cent of water, and is composed chiefly of silica and alumina. The chalk is dug from the hills in the immediate vicinity of the works, and the clay is obtained from the surrounding marshes or brought in barges from the Medway, fuel only not being procurable on the spot.

The mixture of chalk, clay, and water which is now in a creamy state, has been followed to its resting place in the "backs", or large settling reservoirs, constructed on the earth with chalk walls faced with concrete, covering a considerable area (Note 19) and having a depth of 3ft. 6in., where it has to remain until the superfluous water can be allowed to flow away through penstocks having sills, which can be gradually lowered as the deposition of solid material takes place and level of the water in the reservoirs falls. As may be imagined, the settling process occupies many weeks, and the precipitation effected is by no means even, the coarser particles remaining close to the inlets, and the finer ones being floated to more remote regions by the water. When all the moisture, except about 50 per cent by weight, has been removed, the "slurry", as the resulting thick mud is named, is dug out, placed in barrows, and wheeled to and spread upon—to the depth of 6in. or 7in. —the drying floors, large tiled surfaces, under which the flues from the ovens, where coke is prepared for the kilns, pass, and the remaining moisture is then evaporated.

When dry, the "slurry" is loaded into skips and taken to the kilns, into which it is introduced in alternate layers with the coke already mentioned as being produced in the ovens, along with a large addition of gas-coke. The proportion of dried "slurry" to coke is about three of the former to one of the latter by measure (Note 20), but this ratio is constantly varied at the discretion of the "burner", who is engaged in loading the kiln, and who is responsible for its proper performance. The kilns when loaded and heaped up are lighted at the bottom by faggots, and having a capacity of about twenty-three tons yield, they take about sixty hours to burn off (Note 21). When they have burnt out the fire-bars are dropped and the burnt slurry, called "clinker", is withdrawn, great care being taken by those engaged in its removal to pick out all the pieces of cinder and over-burnt material and extraneous matter. Good "clinker" should be of a greenish-black colour free from yellow or pink lumps, and although of a dense, compact nature, not too solid or hard. When it is removed from the kiln, the "clinker" is wheeled in barrows to one of Blake's crushers, where the lumps are reduced to the size of walnut; it is then lifted to a loft above the grinding mills, where it is passed between horizontal stones, similar to those used in flour mills, 4ft. 6in. in diameter, and running at the rate of about 120 revolutions per minute. The powder coming away from the stones is of a greyish colour, and is the finished cement; it should be of such fineness that not more than 20 per cent would be rejected by a sieve having fifty meshes to the lineal inch, or 2500 holes to the square inch (Note 22). After leaving the mill the cement is taken to a large store, where it is filled into barrels or sacks after having been first carefully turned over in considerable quantities for the purpose of mixing and cooling. The packages of cement are loaded into vessels which come alongside the store.

It may be mentioned that at these works there are three wash mills, two as described here and one of a newer form to be described hereafter; fourteen backs, thirty-two coke ovens with drying floors; eleven kilns, two of which are worked on the continuous burning principle; and seven grinding mills. There are four stationary and one portable engine for driving the machinery, and there are two steam cranes. The total indicated horse-power of the engines for washing, crushing, and grinding, at the Cliffe works, is about 250. The ordinary production of a pair of the 4ft. 6in. millstones is 15 to 20 tons in ten hours.

Having described the ordinary—or heretofore most commonly adopted—process, as carried on in the old works, we now come to the large new works which have been recently constructed from the designs and under the superintendence of Mr. Michele. These embody what may be considered the latest improvements which have been successively applied. Several other schemes, some of them possessing considerable merit, were most carefully considered, and the greatest pains were taken to arrive at a sound and impartial conclusion. In these works there are sixteen kilns in one battery (Note 23), each capable of turning out 25 tons of unground cement or clinker, fitted with sixteen patent drying chambers connected with a chimney 200ft. high with a clear opening at the top of 16ft. 8in. The machinery consists simply of four patent wash mills, a set of three-throw "slurry" pumps, a Blake's stone crusher, and six sets of millstones, the whole being driven by a pair of Corliss engines, which work up to 240-horse power, and are supplied with steam by four Lancashire boilers working at 75 lb. pressure. A building to receive and store the ground cement completes the works. The wash mills illustrated (in the previous article) are constructed under Mr. Michele's patent. The pan or tank, vertical driving shaft, harrows, and tines, are similar in their construction and action to those already described, although somewhat smaller in diameter. Instead of being fitted with fine brass wire sieves, through which the particles of chalk and clay have to be carried by the addition of about three times their weight of water, each pan supports on its upper edge a cast iron ring about 9in. wide, built up in segments and serrated on its upper surface; upon this ring, suspended to the lengthened arms of the wash-mill, rotates a similar one which is weighted by bricks. Between the surfaces of these two rings the effluent sludge finds its way, and is by them reduced to the requisite degree of fineness. The advantage of this construction is that instead of having to add a large quantity, about 300 per cent, of water, which acts only as a carrier to pass the mixed materials through the sieves, and as soon as this is accomplished has to be removed, only a very small quantity, about 13 per cent. of water is added, which is found sufficient to insure the due amalgamation of the chalk and clay in the mill and during their passage between the plates. As has been said before, the chalk contains ordinarily about 20 per cent. of moisture and the clay about 40 per cent, so that when they are used in the proportion of 2 chalk to one clay the inherent water equals 26.66 per cent. When to this is added 13.34 per cent, the sludge upon leaving the mill will contain 40 per cent, of moisture (Note 24). This quantity enables the slurry to be conveniently pumped, and is not found too large to be subsequently driven off by the waste heat from the burning process. This waste heat is utilised by the adoption of the valuable contrivance known as Johnson's patent chamber, with the improvements which have been patented by Mr. Michele, and illustrated in our impression of the 14th March, 1879. Each kiln is fitted with one of these chambers—which is of simple construction, and is cheaply maintained. It consists of a 9in. brick arch, 15ft. wide, 5ft. high at the centre, and 65ft. long, extending over top of the kiln in a horizontal direction towards the high chimney, with which its opposite end communicates by means of a short flue. The whole is built "brick-on-end", the portion over the kiln being "fire work", the rest ordinary "stock". There are openings along the top for the admission of the slurry and coke, and for the purpose of ventilation and lighting, as well as for the ingress and egress of the workmen. The abutments of the arches are substantially built, and support two concrete walls, which, with the arches, form pockets on the outside of the chambers, and prevent the slurry intended for one kiln from passing to the next. Into these pockets the slurry is pumped direct from the wash mills, without any intermediate process, and after remaining in them a few hours, the most liquid portion is allowed to flow into the interior of the chamber, where it spreads itself over the floor to a depth of a foot or so. The stiffer portion which has remained in the pockets is then "spitted" up on to the top of the arch (Note 5). The kiln, having been loaded with the previously dried material from the chamber, is lighted up in the ordinary way. The heated gases rise up, and passing through the chamber to the chimney, dry the material in the inside as well as on the top. Thus, the old drying floors with coke ovens are entirely dispensed with, and the expense of making and maintaining them is saved. The dried material being on a level with the tops of the kilns, it is conveniently wheeled to them in barrows, and loaded in the usual way. The head room of 5ft. at the centre of the arch is found to be sufficient for the men to work in without discomfort (Note 25). After the kilns are burnt off, the clinker is drawn out and ground as before described.

In addition to the saving effected by the abolition of coke ovens and sett(l)ing backs, it is found that about 5 per cent. more carbonate of lime can be used (Note 26), and that the quality of the cement produced is more uniform on account of the more even distribution through it of the coarser particles, which in the back process generally settle down near the inlets. The patent wash mills require no skilled attendant, being managed by the loaders engaged in filling the chalk and clay into them. The plates do not require touching when they have been once set to work; they will run between one and two years, when they can be cheaply replaced. The chambers are simple in construction, last well, and require but few and inexpensive repairs. By their use the large quantity of coals ordinarily used in the coke ovens is entirely saved, and the waste heat from the kilns is utilised in a practical and economic manner. From the value of the coals saved must be deducted that of the coke which would have been produced under the old system. Theoretically, a ton of good coking coal should produce a chaldron of coke, which would be superior to that obtained from gas works; but in practice, to obtain increased heat for drying purposes, the ovens are often disturbed, and too much air admitted, so that the chaldron resolves itself into half, and sometimes even less (Note 27); it is therefore difficult to make any reliable comparison, but it may be accepted that the saving in fuel is appreciable, if it does not actually amount to several shillings per ton on the cement produced. We have thus described the two cement works of Messrs. Francis and Co., which may be looked upon as typical, one of the old, or system most commonly in use ; and the other of the new, or that embodying the most recent improvements which have been successfully applied.

Mention has been made of the modes of testing adopted in the first stages of manufacture under the old or "back" system. Under the new system the test for carbonate of lime is applied, with the addition of a simple daily test to ascertain the percentage of water in the sludge as it leaves the wash mills. The small sample kilns are dispensed with, as they are not found to be necessary when the time occupied by the whole process of manufacture is reduced from about eight or ten weeks to very nearly as many days. Under both systems, as the ground cement issues from the mill-stones it should be sampled almost every hour, and pats made and immersed in water as soon as set, in order to at once detect any excess of lime. Briquettes also are made every day from this freshly-ground cement, and their tensile strength tested at two or seven days. Further, the powder is frequently sampled and tested for strength both in the store-shed and as it is loaded into vessels upon leaving the works. There is little doubt that were it practicable no cement should be allowed to quit any works until it has satisfactorily passed a seven days' test for tensile strength, but in consequence of the large masses of material dealt with, and therefore the enormous extent of warehouse room for storage required, to say nothing of the extra cost of labour for moving which would be entailed, it is not found to be possible to insist upon such a practice being always adhered to, although in some special cases it is. It is the custom in some specifications to insist that all the cement used shall be tested upon the works for which it is intended, and the manufacturers are sometimes bound to remove at their own cost any which will not withstand a given tensile strain. The result is that when the guaranteed test is a very high one it is necessary for the manufacturers to charge an unusually high price for their produce, in order to cover the exceptional risk which has to be undertaken. It would seem to be more advantageous to all concerned if the cement could be always tested, as it now sometimes is, by competent persons before it leaves the manufactory. This practice reduces the manufacturers' risk considerably, as in the case of a heavy cheap material like cement the cost of carriage to the spot where it is used often amounts to a very considerable portion of its total value, and it saves the user the expense of erecting large stores to contain the cement whilst it is being tested, as well as the risk of damage by damp, which must necessarily be greater in what are usually temporary structures than in the properly constructed permanent stores at a cement manufactory (Note 28).

It may here be well to describe in detail, for the information of those who may not have had occasion to test any cement, the usual method pursued. The powder is first filled as tightly as possible into an imperial bushel measure and weighed. It is considered that this quantity should not weigh less than 112 lb., but it often weighs more. If the weight is less than 100 lb., it will probably be found that the cement has been imperfectly burnt. After ascertaining the weight per bushel, a small quantity is again weighed, and then sifted by means of a sieve with fifty holes to the lineal or 2500 holes to the square inch. The residue obtained should not exceed 20 per cent. of the total weight of powder under trial. The cement should be ground to this degree of fineness, but Mr. Michele considers that it should not be sifted, as by the use of a sieve the hardest and, in his opinion, the best particles are removed. The next test, for the purpose of ascertaining if there be any excess of lime, is conducted as follows:—By the use of a trowel, the powder, with the addition of as little water as possible, is mixed up to a stiff paste, with which small pats are formed, which are immersed in water on pieces of slate as soon as the cement is set. If there are no cracks visible on their surface, after immersion for forty-eight hours, it is generally considered that there is no dangerous excess of lime, although there can be no doubt that it is better to extend the time to three days, or as long as possible (Note 29).

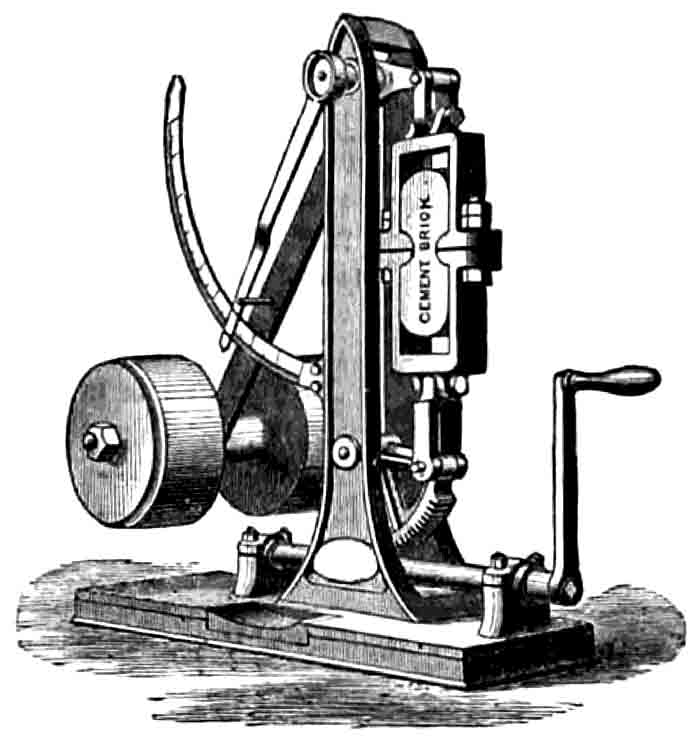

The next test applied is that for tensile strength. At the time the pats referred to are made, some of the stiff paste is carefully placed in brass moulds, which are so constructed that after forming "briquettes" with accurate breaking sections of 1½in. by 1½in. equal to 2¼ square inches in area, they can be easily removed. These "briquettes" should be made with great care, and only by those who have had considerable experience in their formation. Slight inattention or want of the requisite knowledge on the part of the operator will be the cause of perplexing and contradictory results. The briquettes are usually left in the moulds for twenty-four hours, when they are removed and immersed in water until the seventh day from that on which they were made, when they are tested in one of Mr. Michele's machines illustrated herewith (Note 30). It has been found that the best cement so tested should be capable of withstanding a tensile strain of from 300 lb. to 350 lb. per square inch. Though briquettes having a breaking section of 2¼ square inches are used in conformity to established usage, Mr. Michele urges the desirability of substituting an area of one square inch. No substantial arguments can be advanced in favour of the larger section, and it has many inconveniences. To revert to the tensile strength of Portland cement, although as much as 500 lb. and upwards per square inch at seven days has been obtained, it is found that with the existing appliances for manufacture these high strengths are sometimes obtained at the sacrifice of ultimate strength, on account of the high proportions of lime which must be used. The strongest and best cement is that which contains the greatest proportion of lime properly combined with the silica and alumina of the clay. If there is even a slight excess of lime—that is, free, uncombined lime—the cement will sometimes withstand a high tensile strength at seven days, but will be found to depreciate instead of improve in strength afterwards. Too much attention cannot be paid to the test for lime, for if there be any of this free, sooner or later it will make itself known, either by the work for which it has been used showing signs of cracking or crumbling, or by its total collapse. No doubt the first consideration is to obtain the strongest possible cement in order that it may form an effectual matrix for the greatest number of particles of sand or other foreign material, but it is also obvious that unless the strength is permanent or increasing it is valueless. Thus, the cement which really presents the best and most lasting qualities is not necessarily that which shows the highest tensile strength at seven days (Note 31). There are many practical difficulties in the way of extending the age of briquettes before breaking from seven to fourteen or twenty-eight days, though such a practice would enable a more accurate estimate to be formed of the material tested. Mr. Michele seems to consider that for the present the best cement may be secured by a specification which ensures an average tensile strength of 300 lb. to 350 lb. per square inch at seven days, coupled with a strictly enforced test for lime. Briquettes may be broken at four days as well to enable some opinion to be formed of the growing strength of the cement between that age and seven days, but the results so obtained must only be taken with due regard to the time the cement takes to set in the first instance. A quick-setting cement will show but little improvement in strength between four and seven days, whereas one which takes many hours to become firm will often show a very considerable increase of strength in the same period.

It is impossible to foretell what may be reached in the future. Judging by the strides which have been made during the last ten years in the direction of improving the tensile strength of Portland cement, it might be assumed that before the lapse of another similar period strengths of 500 lb. and upwards per square inch at seven days will become common. There is, however, a danger in specifying too high degrees of strength at present. The first aim of an engineer who is responsible for works constructed with Portland cement, is the production of a material for him with the highest possible tensile strength, but at the same time without containing any excess of lime which has not become properly combined in the process of manufacture, and which is therefore liable to expand and disintegrate his structure. The mode of testing above referred to when strictly adhered to will, it is believed. ensure a practically safe cement under the present mode of manufacture, but fresh means may have to be devised in the future. Before, however, any great and striking improvement in the quality of Portland cement can be expected, it would seem to be necessary that the fundamental principle involved in the setting or hardening which takes place when water is added to the powder should be understood chemically. Although several hypotheses have been enunciated to explain this remarkable property of cement, none of them seem satisfactory to chemists. This is a most important question and one which merits the attention of chemists and physicists as well as engineers, for it has an important bearing upon the stability of some of the largest engineering works in the world.

NOTES

Note 1. The block of twelve kilns corresponds exactly with the block that remained at the Quarry plant and still stands, except that the block was extended at some time (before 1895) to sixteen kilns. Later photographs of the block show the stack still placed in the centre, so a pair of extra kilns must have been added to each end.

Note 2. Vitale Domenico de Michele (b. 11/11/1848 Westminster, d. 21/3/1906 Rochester) was the fourth son of Charles Eastland de Michele who had been editor/co-owner of the Morning Post and was British Consul in St Petersburg for most of 1849 to 1866. His great-grandfather had been born in Italy. His many siblings had very conventional English names, and his own names were presumably the result of the effusion of Italian nationalist sentiment that occurred during the year of his birth. Following education at Westminster, he was in 1865 apprenticed in engineering with Robert Stephenson at Newcastle-on-Tyne. His father, on returning from Russia, joined Francis & Co. as a partner in 1868, and Vitale was brought back (reluctantly) to manage the Nine Elms plant. He was accompanied in his move from Newcastle by another Stephenson alumnus - Reginald Empson Middleton (b 1844 St Bees, d 1/7/1925), who seems to have played a large part in the many inventions that Vitale claimed as his own. His father became senior partner in the firm in 1871, after the death of Alfred Francis, and Vitale was made junior partner. While continuing to manage the plant, he and Middleton also established in 1876 a private consultancy, working from an office in Westminster. With Middleton and William Holcombe Francis, he set up "Empson, Holcombe & Co" as a ghost company to independently acquire and develop I. C. Johnson's part of the Cliffe site. After amalgamation of this, the Nine Elms plant and Johnson's Quarry plant in 1886, he managed the whole site. When Francis & Co sold out to APCM, he "severed connection" with the cement industry.

Note 3. Readings from the figures and the OS map confirm the dimensions. Each kiln was 18' wide overall, with the kiln diameter and chamber internal width 15'. The stanchions in Fig. 2 are 10' apart, so it appears that the central duct was about 8'6" wide. The chambers were 65' long, and the kiln sections were 20' long. As mentioned later, the early Johnson chambers were 100' long. It is therefore difficult to see how this block could have been modified from a Johnson original, and the theory that this kiln plant was originated by Johnson appears less likely. Johnson developed his chamber kiln design at Gateshead.

Note 4. There was no reason to put a roof on a Johnson kiln. A Michele kiln might have worked without a roof, but a rain storm at the end of the burn would have caused difficulties.

Note 5. Michele was an engineer, and not a chemist. Portland cement - a chemical product - can only be made by chemists. This practice was guaranteed to un-mix the slurry and cause gross inhomogeneity and poor quality of the product. Later manifestations of the design filled the inside and outside surfaces separately.

Note 6. Thinner brickwork - one course of bricks on end instead of two used by Johnson - was needed to improve heat transmission to the outer layer of slurry. However, the arches were notoriously fragile, and with the necessity of operatives to clamber over them, were the cause of many accidents, some fatal.

Note 7. This is the patented Goreham process, first used at Swanscombe in 1870.

Note 8. This is another engineering solution. The design appears to have been adopted at a few other locations, but later developments in washmills did not use the idea. The distance between the grinding surfaces of 4'6" stone mills was traditionally adjusted with a cigarette-paper shim. Intuitively, the problems here involved in keeping the grinding surfaces at the correct separation must have been insuperable, in addition to the problem of getting the slurry to go through the gap. The fact that the grinding plates were claimed to last two years is sufficient evidence that they did very little grinding.

Note 9. It is clear from these articles that the whole Cliffe site, with three separate manufacturing centres, was under the control of Francis & Co., although this was not formalised until 1886, when the limited company was established. Kelly's Directory 1882 entry for Cliffe lists Francis, Empson Holcombe and I. C. Johnson as three separate companies selling cement, but Empson Holcombe, as discussed above, was a "ghost company". It's not clear what I. C. Johnson was doing at the site; his plant at Greenhithe was under way in 1877, and was the focus of his attention. However, at the 1881 census, John Lamb Spoor, Johnson's kiln expert, was in lodgings at the "Cement Cottages" in Cliffe, having just moved from the Tyne. Was he working for Johnson? Or for Michele? The Johnson directory entry might have been a purely commercial presence.

Note 10. Nine Elms and Quarry, but not Cliffe Creek.

Note 11. Alfred Trelawney Giles (b 3/10/1816 Westminster, d 3/3/1895 Westminster) consulting civil engineer: early expert in concrete construction.

Note 12. This is a fact not always recognised, even today.

Note 13. 1% CaCO3 content was equivalent to about 14% tricalcium silicate in the clinker in the mix in question.

Note 14. The calcimeter illustrated was a comparatively primitive early version. A more advanced version was already in use by 1882.

Note 15. This is nearly the case: southeastern chalks contain 1-3% dolomite, but the amount is fairly stable within a given deposit.

Note 16. Like all analyses of this period, this needs to be regarded sceptically. The "sand" entry is essentially an acid insoluble residue, but done extremely ineptly, so it usually includes some silica that should have dissolved. Iron is usually over-estimated, but perhaps not here. In raw materials, magnesia is assumed to be in the form of carbonate, although, particularly in the case of the clay, this is not the case. This assumption is problematic if the lime is being assessed from the balance of the carbon dioxide. The analysis of the hydrated cement is daft, but at least serves to show that more than one cement analysis was possible. The fifth column is my own, calculated from the hydrated cement by removal of the water.

Note 17. The moisture content of this slurry is, as shown below, about 82%. This had the advantage that coarse material separated out by sedimentation. The process had its origin in the production of ultra-fine slips for ceramics production.

Note 18. The chalk contains about 5% flint: the flint was rejected by the washmill, and the "sand" was probably a mixture of broken flint fragments and superficial sand infiltrated into the chalk joints.

Note 19. The area on the OS map was about 3800 m2. Interestingly, a depth of 3'6" implies a volume of only 4050 m3, containing at the given moisture content only 840 dry tons of raw material, which is only 23 kiln charges, or 2.6 weeks run for nine kilns. Slurry backs were typically left for at least twice this time, so either the kiln throughput on Portland was much less than capacity, or the moisture content was a lot less than that implied here.

Note 20. This volumetric ratio corresponds to around the typical 45-50% coke on clinker, depending on bulk densities.

Note 21. 2½ days; with 1½ days to cool and a day each to load and unload, this makes the six-day working week.

Note 22. This corresponds to a particle size of about 300 μm, exemplifying the extremely coarse cement of the time. In modern cements, the 20 percentile particle size is about 25-30 μm.

Note 23. As mentioned above, the original twelve had been expanded by adding two more at each end of the block.

Note 24. So a 300% water addition has been reduced to 13%! Those familiar with such calculations will immediately spot the error - but a patent agent wouldn't! This is how it really works:

| Total Weight | % Water | Dry Weight | Water | |

|---|---|---|---|---|

| Chalk | 2.000 | 20.0 | 1.600 | 0.400 |

| Clay | 1.000 | 40.0 | 0.600 | 0.400 |

| For "thin slurry" process | ||||

| Water | 9.000 | 100 | 0 | 9.000 |

| Slurry | 12.000 | 81.7 | 2.200 | 9.800 |

| For "thick slurry" process | ||||

| Water | 0.667 | 100 | 0 | 0.667 |

| Slurry | 3.667 | 40.0 | 2.200 | 1.467 |

0.667 tons of water is 22.2% of the 3 tons of wet raw material.

Note 25. I doubt if this conclusion was the result of a poll of the workforce. Conditions in the chambers were hot, humid, dirty, dusty and toxic, and involved heavy lifting while at a permanent stoop (unless children were employed).

Note 26. This is rather startling until you notice in the table of analyses the very low base (70%) from which they were starting.

Note 27. It should be remembered that, even when worked efficiently, these coking ovens were for the production of coke and not gas, and most of the volatiles, containing perhaps half the heating value of the coal, were lost up the stack.

Note 28. This talk of producer- and consumer risk prefigures modern quality assurance talk. The very real risks existing at the time were largely the result of the variability of every stage of the manufacturing process, and consumer-risk reduction consisted of identifying and rejecting defective product before it left the site - always a difficult problem when defects might only emerge months or years after use. This was a long way from a "zero-defects" operation, and the move to chamber kilns, if anything, made the situation worse by eliminating a vital blending stage.

Note 29. The obsession with the possibility of excess lime, in the context of the clinker chemistries shown in the table above, with LSF 75-85, testifies to the chemical variability normally encountered - the LSF was expected to occasionally stray over 100.

Note 30. It was claimed that hundreds of Michele test machines were sold, but they never became the accepted standard - the machines most specified were made by instrument makers like Adie and Avery. The design had the problem that the hand-cranked increase of load transmitted vibration to the test piece and contributed to low results. Later models were hydraulically actuated, and more stages of leverage were added. Another intriguing point about the design is that the standard briquettes had a cross-sectional area of 2¼ sqare inches, so a briquette with a strength of 350 psi needed a breaking force of 787.5 lbf. The counterweight at full extension was only capable of producing 1000 lbf, which is perhaps why Michele was pleading for a smaller briquette, while also disingenuously suggesting that strengths over 350 psi were a bad idea.

Note 31. It's almost as if he's arguing in favour of low strengths! In addition to the minor consideration mentioned above, it seems likely that the plant was having difficulty in getting strengths over 350 psi (8 MPa in modern EN 196 testing) - and he was denigrating the achievements of those (particularly continental producers) who had been more successful.