The following are transcripts of two anonymous articles that appeared in The Engineer, 87, 30/6/1899, p 644, and 98, 1/7/1904, p 22, both of which are believed to be out of copyright.

The initially small and failing Whickham cement plant had been taken over by Martin and Earle in 1895, and a programme of rapid expansion ensued. By the time of the first article, the plant had expanded ten-fold, and was planning a further doubling of its output (which due to the 1899 depression, did not happen). The active partner, Edward John Vavasour Earle (1851-1923), was planning to break the exclusive, sclerotic industry Establishment, and was trying to get the other Medway manufacturers to join an alliance that would out-perform the likes of Whites and Hilton, Anderson and Brooks. In this he was out-manoeuvred (see APCM formation), and by the time Martin Earles was taken over by BPCM, he had been ousted. In retrospect, Earle's strategy involved much more brawn than brain, and the fulsome description in the article was no doubt part of the campaign.

A certain amount of ingratiating hyperbole was normal in such accounts, and the first article stands out in this regard. The description is of what is in fact a plant with decidedly backward technology, its only virtue (and that much exaggerated) being its size.

Values of imperial units (as of 1904) used in the text (alphabetical order): 1 acre = 0.40468424 Ha: 1 ft = 0.30479947 m: 1 gallon = 4.5460756 dm3: 1 HP (horse-power) = 0.7456998 kW: 1 inch = 25.399956 mm: 1 psi (pound-force per square inch) = 6.89478 kPa: 1 ton = 1.01604684 tonne: 1 yard = 0.91439841 m.

THE CEMENT WORKS OF MARTIN, EARLE, AND CO., LIMITED.

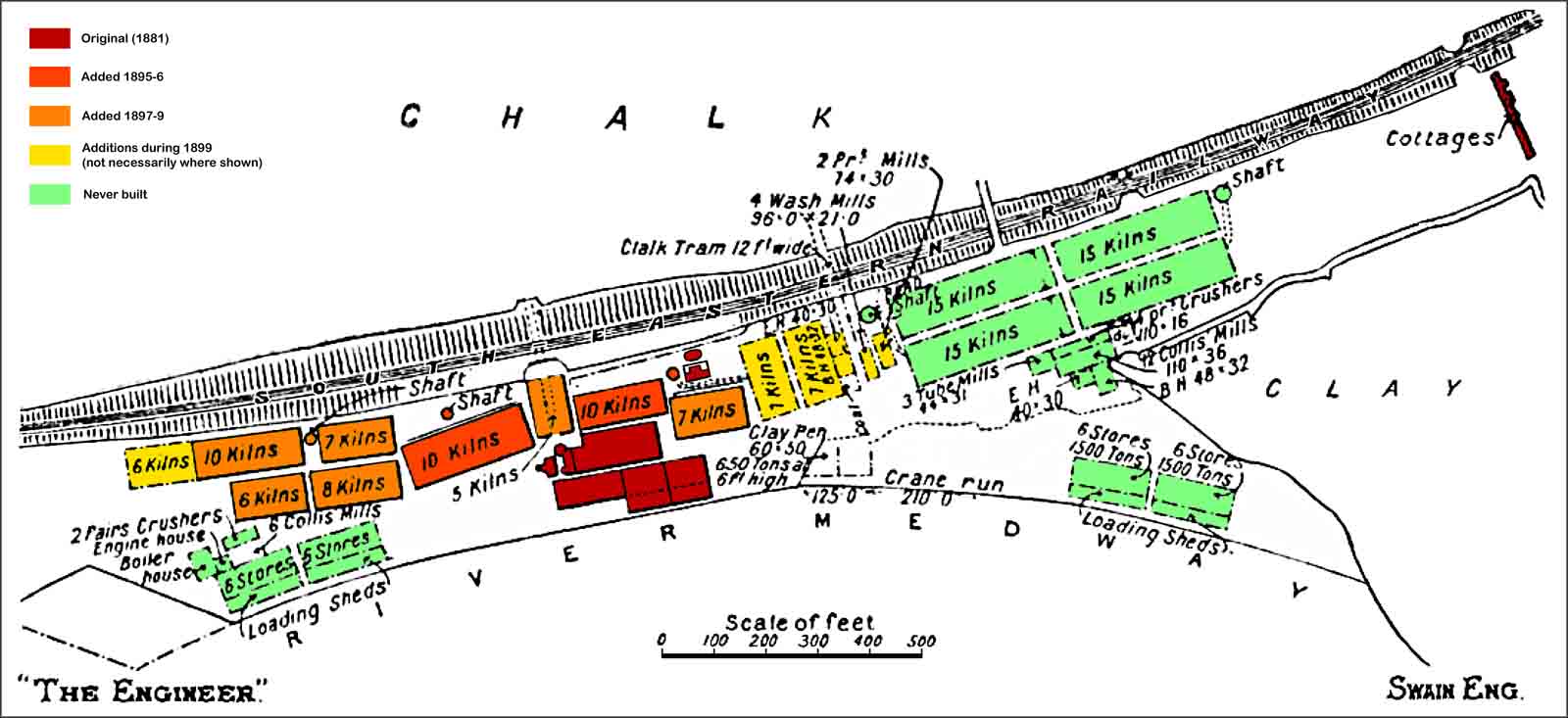

THE Wickham Cement Works of Martin, Earle, and Co., Limited, are situated on the north bank of the river Medway, a little higher up stream than Rochester Bridge. The site could not have been better chosen (Note 1), and it forms an ideal situation for cement manufacture. It is true that coal and coke have to be brought from a distance, but with the exception of these every other requisite is near at hand on the premises. As is, of course, well known, the original ingredients required in the manufacture of cement are chalk and clay (Note 2). These exist in abundance on the company's property; indeed, we are informed, there is sufficient for at least 300 years' working (Note 3). Moreover, both the chalk and the clay are easy to obtain (Note 4), and the machinery has been placed in the most central portion of the works, having regard to all considerations. The foregoing do not by any means form the whole of the advantages possessed by those works, a plan of which we give in our illustration. There is a frontage of about half a mile to the river Medway, and a wharf has been built along the whole of this. When we had an opportunity of visiting the works there was a fleet of no less than twenty-five barges lying by the wharf in the course of being loaded, or waiting to be so. These barges, or some of them, bring coal and coke to the works on their return journeys after discharging their cargoes of cement at their destinations.

By means of the river, too, lighters are sent down loaded to an ocean-going steamer, the property of a small affiliated company, which can come up to just below Rochester Bridge. By thus doing its own carrying, as it were, the Cement Company can deliver its goods with the least possible expenditure. Most of the long distance traffic is done by water, but the local demand is satisfied by means of the two railways - the South-Eastern and the London, Chatham, and Dover - which run actually through the property. Sidings have been constructed in connection with these railways, one of which the - South-Eastern - comes right through the manufacturing portion of the works and between it and the chalk pit, while the Chatham and Dover lies a few hundred feet farther north of the South-Eastern, and only the large scale of our illustration prevents it being shown. The company owns seventy acres of land, with possession of all mining rights of all kinds, while it leases thirty acres in addition, with power to remove the chalk from these. Good water is present in large quantity at but a small distance from the surface, and altogether it may be said that the site has been chosen with the utmost skill, and developed with every regard to utilising all these advantages to the utmost, and with an eye to future developments.

Referring to the plan, the chalk lies to the northward of the railway, and is approached by two tunnels underneath this, while a third is shortly to be constructed. The chalk is at the present time being worked down to a depth of some 80ft. from the ground level, which brings the working level down to a little higher than the level of the works, so that loaded trolleys can travel on the small tram lines which are laid down from the chalk workings into the works almost by themselves. There is a depth of chalk of some 30ft. below this level, however, which could be worked if necessary. We have previously stated that there is a supply sufficient for 300 years, so probably it will be many years before this portion of the chalk is touched. The chalk itself is of considerable purity, averaging, we are told, about 92 per cent. of carbonate of lime, and it is very homogeneous in character, and varies but little over a large number of samples. At present it is brought from the pit into the works by hand labour, the incline rendering the force necessary to propel the trolleys or trucks very small - not more than one man can easily manage. When empty there is no difficulty in returning them up the incline; but shortly this is all to be done by means of endless ropes. This system is also being adopted for a method of aerial conveyance of chalk, where it will no doubt be very successful. This is for taking the chalk from the pits to places from which it can be carted or taken from the works by other means, for the company is in the enviable position of being able to supply chalk to cement manufacturers who are unfortunate enough to have run through their supply of this necessary to their manufacture - a not unfrequent (sic) occurrence among the makers in the surrounding district. This in itself forms no inconsiderable item in the revenue of the company (Note 5).

The process of manufacture of the cement, as carried out at these works, is as follows:- As the chalk is quarried it is taken on tram lines to what are known as "wash mills". These are circular brick-lined pits, in each of which revolves a "spider", the arms of which carry implements much like harrows in construction. As the spider revolves, the harrows catch the lumps of chalk and break them up. With the chalk is added a certain amount of clay, the proportions being, roughly, two-thirds of chalk to one of clay. The addition of the water allows of an intimate mixture of these two substances, and when sufficiently mixed the "slurry" escapes through a grating into a catch pit. From this it is taken up either by bucket wheel, or by an endless chain of bucket wheels to a higher level and delivered into the "rough mills", formed of rough " burr " stones placed horizontally (Note 6). From these it flows in a thick cream, and is led to the "mixers", which are in sets of two. They consist of circular pits, like the "wash mills", and in them revolve four-armed spiders carrying "stirrers". In the "mixers" at present at work these "stirrers", of which there is but one to each "mixer", revolve in one direction. Shortly, however, each "mixer" is to be provided with two stirrers mounted on the same axis, but made to revolve in opposite directions, by which means the time taken to obtain a perfect mixture will be materially lessened. The slurry flows from one "mixer" to the other - the two closely adjoining one another - and, during its progress through these, samples are taken every half an hour to the testing shop so that a continuous check is kept on the composition of the mixture. The "slurry" is now ready for drying previous to "burning". Both these processes are conducted at one operation in one kiln, the method adopted varying slightly with the different type of kiln. A description of one will suffice for the whole, for, though they differ in detail (Note 7), the general principle remains the same. Speaking generally, the kilns consist of two parts - the kiln proper, and the drying tank or floors.

In the kiln are placed alternate layers of coke and dried " slurry." The burning creates a great heat, and the heated gases are led either under or over the tank or floor into which the "slurry" has been pumped to a depth of some 9 in. or 10 in. The action of the kilns is therefore twofold: burning one "charge" while drying and preparing the next charge for burning. The period necessary for adequate "burning" varies somewhat, but it may certainly be taken that three complete "charges" can be passed through each kiln in a fortnight (Note 8). The clinker is now removed, and the slurry, which is now dry and cracked all over, is dug out of its tank and placed in its turn in the kiln, with alternate layers of coke. The slurry tank is again filled, the furnace closed, and the process repeated. The heat used is just below that of the fusing points of the materials, and it is here where, with the exception of the mixing, the greatest skill is required. The burning has, of course, to be carefully watched day and night, and the temperature regulated by means of dampers. Laying the "fire" also requires considerable experience, for there must be just enough coke, and not too much. "Enough", because under-burnt clinker is useless for cement, both in colour and properties; and "not too much", for otherwise the heat is too intense, fusion takes place, and the resulting material rendered of no use on this account. The, clinker, as it eventually comes from the kilns, is grey in colour, and extremely hard. It is also porous, and is not unlike light-coloured coke in general appearance (Note 9), being pierced with numberless minute holes. One is tempted to ask, when looking at this clinker, "How much coke remains in its composition?" so great is the resemblance of the one to the other. And the answer received is, "None at all". All gets burnt away, as a fact, though from appearances it would seem otherwise.

The clinker stage arrived at, there yet remains the crushing, grinding, and production of the cement proper, and to this branch of the subject the company has evidently given the greatest amount of consideration and thought. There is practically no machine which it has not tried, and several kinds are now at work. These are of widely different character. One is not unlike the ordinary mortar mill in general principle (Note 10); another, the "ball mill", consists of a large cylinder containing balls, which as the cylinder revolves are lifted up and fall on the clinker as it passes through the cylinder. The type, however, which meets with most general approval resembles in construction a pestle and mortar. This machine is of American design, and the company is so satisfied with its performances that it is just about to install a large number of this type of machine. The practical result is to do away with sieves - that is to say, sieves as separate machines to the grinders, for they produce an extremely large proportion of "flour" (Note 11). One of these machines is now at work producing cement, and the parts of a large number of others are on the premises awaiting erection. As regards the numbers of the various kinds of machines, &c., which are now at work there are four "wash mills", ten "rough mills", four "mixers", and nearly a hundred kilns (Note 12), besides numerous crushers, grinders, sieves, &c. The general output at the present time is about 2000 tons per week. Extensions of the buildings and machinery are, however, in course of construction which will in a short time allow this output to be doubled, and then this will be without doubt the largest single cement factory in the world (Note 13).

The motive power for all the machinery throughout the works is obtained from steam engines. There are two principal engine-houses. One contains three vertical triple-expansion engines of 600-horse power each. These drive on to shafting by means of cotton ropes. Steam is generated here in four marine type boilers. In fact, one might almost imagine oneself in the engine-room or stokehold of a ship, such an air of the sea is there about all the arrangements. The engines are condensing, and the water is obtained from wells sunk on the premises, the water, after it has been through the condensers, being allowed to flow back into the wells again. The second engine-house contains an old beam engine, which, though old, is still doing excellent work. It is supplied with steam from three Lancashire boilers, only two of which are at work at one time.

The works are very imposing to look at. There are already seven large chimneys, varying from 180ft. to 220 ft. in height, and others are in course of erection. Most of these are for receiving the gases from the flues of the kilns. The arrangements of both the old and the new buildings is excellent, and we may here say that in our illustration the extensions in course of construction are shown by dotted lines (Note 14). The working portion is in each case kept as near to the chalk as possible, so as to save carriage of this further than is necessary. Then when the cement is made, and is in such a form that it can be more easily carried, it is taken to the " stores " in conveyors. The stores are situated on the quay, along which run steam-worked travelling cranes. The quay has recently been very largely extended by the company, having been taken some 300 or 400 yards down stream to the opposite shore of a small bay in the river. The land enclosed by this wharf is now being reclaimed, the filling-up material being obtained from another portion of the works, which is being levelled for building the extensions. This will be a large gain to the company, and will enable it to extend its buildings without encroaching on land which will yield either clay or chalk. It is evidently intended to expand as much as possible, as is shown by the work now in progress, and by the expressed intentions of the directors. Moreover, the company is its own builder, and is itself carrying out the erection of its new buildings. These will contain, as will be seen from the plan, eighty new kilns, with their necessary "wash mills", "crushers", "grinders", engines, boilers, &c., and also of five new stores, capable of holding together some 9000 tons of cement. The present storage capacity is about 7500 tons, so that in a short time the combined storage capacity will be some 16,500 tons.

We have previously mentioned that the slurry is tested continuously. This also applies to the cement, and the test of the briquettes made the week previous to our visit gave an average breaking strain of 485 lb. to the square inch (Note 15). We witnessed the test of a briquette selected at random by ourselves. This had been made just over a year, and it did not break until subjected to a strain of 1000 lb. to the square inch. The tests are carried out in a small building neatly fitted up as a laboratory. The offices are contained in an unpretentious building constructed entirely of cement, the inside fittings being of pitch pine.

A feature in cement manufacture is, of course, the large amount of money which it is necessary to expend on repairs and upkeep, not only of the kilns, but of the machinery. We are informed that until recently the bill at the Wickham works for this latter item amounted to no less than £700 a month. The company, being naturally desirous of paying as little as possible for these necessary repairs, instituted the idea of erecting an engineering shop, so as to do the work itself. This turned out to be so successful that this part of the works has been largely extended ; and now an engineering business has been added to the manufacture of cement, it having been found that plenty of work can be and has been obtained to keep a large establishment busy. Among other things now in course of construction are a pair of 600-horse power triple-expansion engines, destined for the extension of the cement works, and a considerable amount of outside work. The saving of expense in regard to the repairs alone is said to amount to as much as £400 a month. The formal opening of these engineering works took place on the 17th inst., the ceremony being performed by Lord Cranborne (Note 16). The works consist of a large erecting and fitting shop, driven at present by a Davey-Paxman horizontal engine. The building is lightly but substantially erected of steel girders and corrugated galvanised iron, and is exceptionally well lighted. One noticeable feature is that the shafting for actuating the machinery, instead of being overhead, is down on a level with it, and placed well out of the way. A number of machines are already at work, and many more are on order. There is also a foundry and smith's shop, and the beginnings of a boiler shop, for the company evidently intends to do all its work itself. A pattern and carpenter's shop adjoins these buildings, and close by are the offices, contained in a substantial brick structure ; all of these being in a most forward state. A line of railway connects the engineering shops with the cement works and thence to the railway, a distance of some few hundred yards. It certainly is a novelty to find a cement works developing an engineering business, but this is what has happened here (Note 17).